1965 Impala Hell Project Part 6: Gauges! Switches! Buttons!

When we last saw the 1965 Impala Hell Project, it was the fall of 1990 and I was installing headers, dual exhaust, and a TH350 transmission in place of the original Powerglide. The car drove pretty well with those upgrades, but the fact that the entire instrument panel (except for the oil pressure idiot light) was kaput became quite an annoyance. Was the engine running hot? Was I going 80 in a 45 zone? How much gas do I have? Those questions remained mysteries, and finding functioning replacement parts for a then-26-year-old car in the junkyard would be tough. I had a solution, however; scavenging Pick-Your-Part for instrument-panel components on Half Price Day weekends and building my own instrument panel from scratch.

The factory instrument panel looked cool, but there was no way I’d be able to buy new replacement gauges on my recession-grade office-temp wages. Once I had all the parts I needed, a “DIP” street sign I found somewhere (no, I didn’t steal it) donated some high quality aluminum sheet and I was ready to go.

The car was developing some nice patina at that point; I’d taken to hitting it with black or gray spray paint whenever I spotted any sort of scratch or blemish in the gloss-gray industrial paint that the previous owner had hosed over the original Tahitian Turquoise paint.

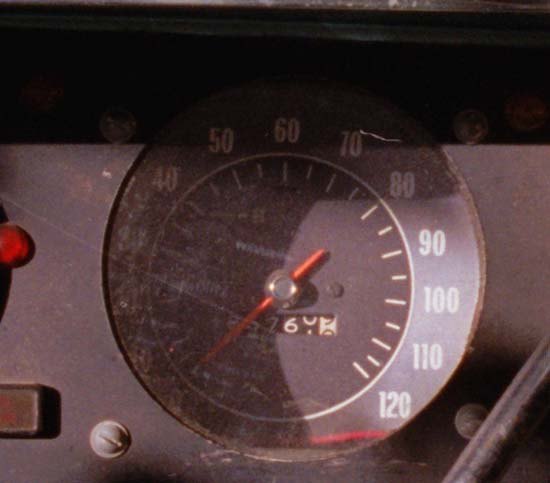

After determining that just about all GM cars of the 1960s shared a common speedometer-cable connection, I scored this speedo out of a late-60s Buick. A Wildcat, perhaps? In any case, it was round, it looked cool, and the donor car had a similar differential gear ratio to the 3.31 in my Impala’s 12-bolt.

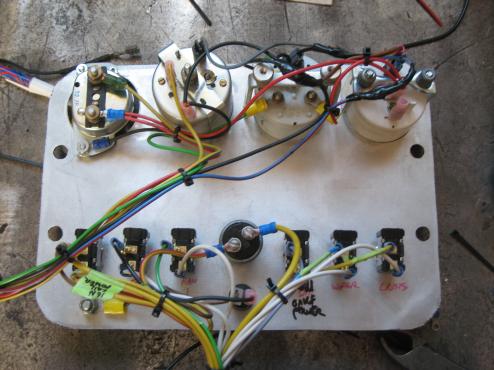

This is the only photo I can find of the aluminum panel that became the new dashboard (damn pre-digital photography era!).

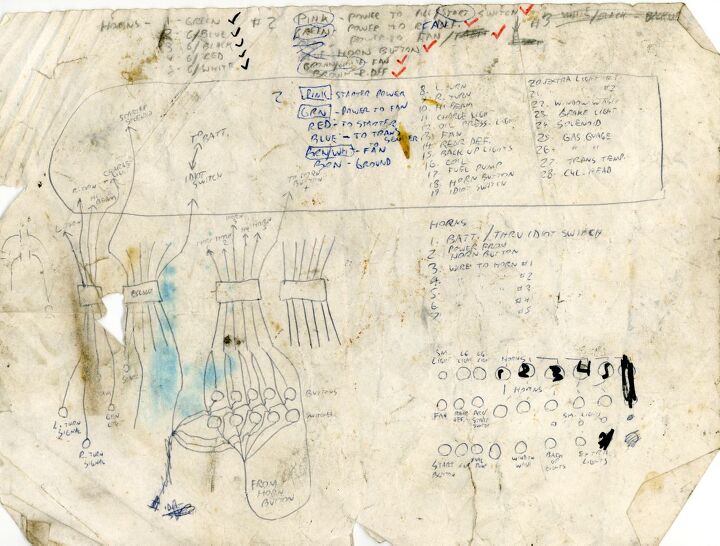

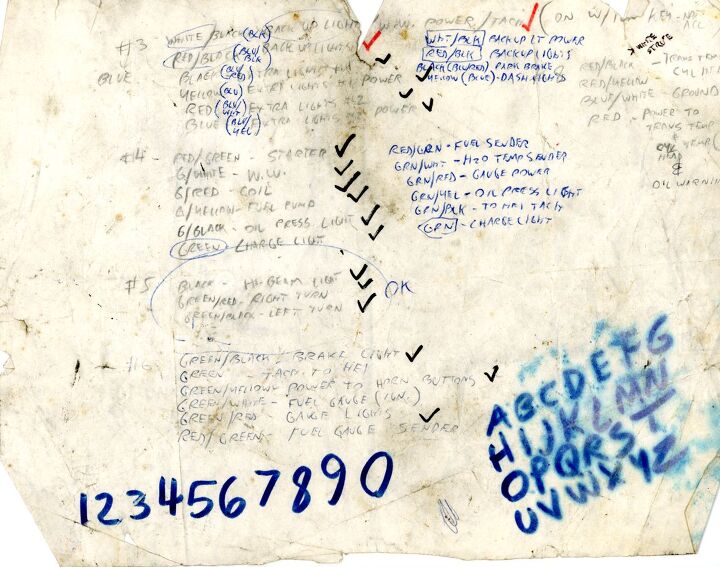

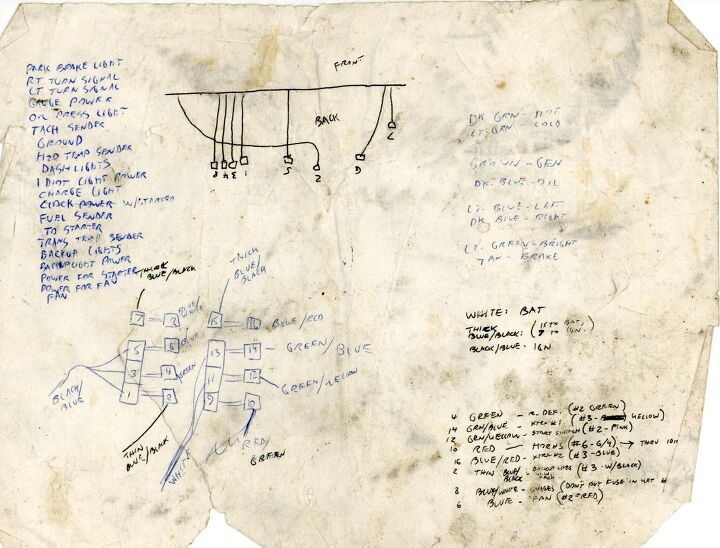

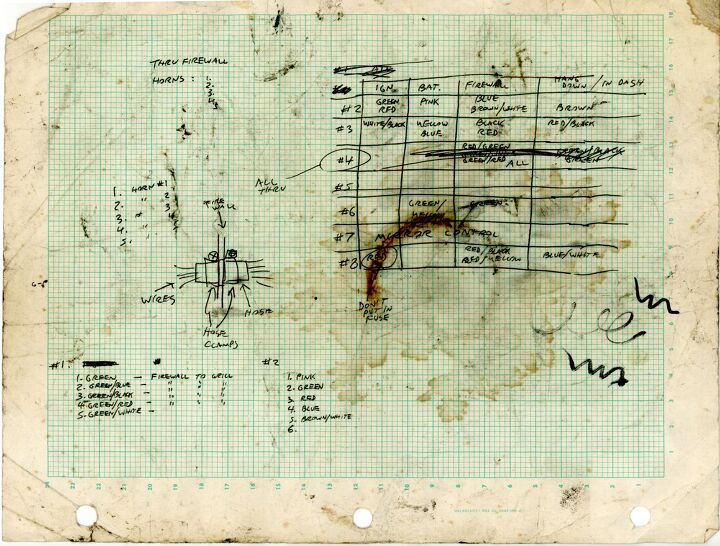

However, I do still have the original diagrams I drew up to help with the wiring. They’re pretty thrashed, because they spent 10 years in the car’s glovebox. I got a lot better at this sort of thing a few years later, when I became a technical writer, but at least these diagrams are quasi-intelligible.

I used junkyard connectors scavenged from Toyota and Nissan wiring harnesses, with surplus wire bought cheap at the legendary (and now defunct) Mike Quinn Electronics. Quinn’s, as San Francisco Bay Area electronics geeks recall, provided much of the raw material for the Grateful Dead’s scratchbuilt sound system in the mid-1960s; a decade later, Jobs and Wozniak bought many of the components used in the prototype Apple I computer there. That gave my Impala provenance!

Most of the toggle switches also came from Quinn’s, but I decided to go Italian with the warning lights. Fiats used these beautiful metal-and-glass units in their cars for years.

Back in 1991, it was pretty easy to find Fiats in self-service junkyards, so I gathered a good-sized collection of stylish indicator lights. In fact, I still have a stash of them to this day (even after using many of them in the Junkyard Boogaloo Boombox a few years back).

When it was all assembled, my car had a cockpit that looked like something out of the Space Shuttle: Voltmeter, vacuum gauge, tachometer, speedometer, transmission temp, oil pressure, water temp, fuel, clock— everything from the junkyard. For switches, I had just about everything possible wired up, including a James Bondian taillight-cutoff switch and wiring for five separate horns (inspired by the multiple horns in my ’58 Beetle; unfortunately, I never did get around to installing additional horns in the Impala). The speedometer was mounted to the back of the instrument panel with a plywood spacer, and I installed red and green speedo-face lighting in the spacer (with a three-way switch to control lighting color).

The Kienzle clock came from a 1966 Opel Kadett, featured an Opel emblem and was the gauge that pleased me most. I’d found it in U-Pull-It Auto Wrecking in Oakland during my earliest junkyard expeditions, installed it in my Beetle during high school, and hung onto it long after the Beetle got crushed.

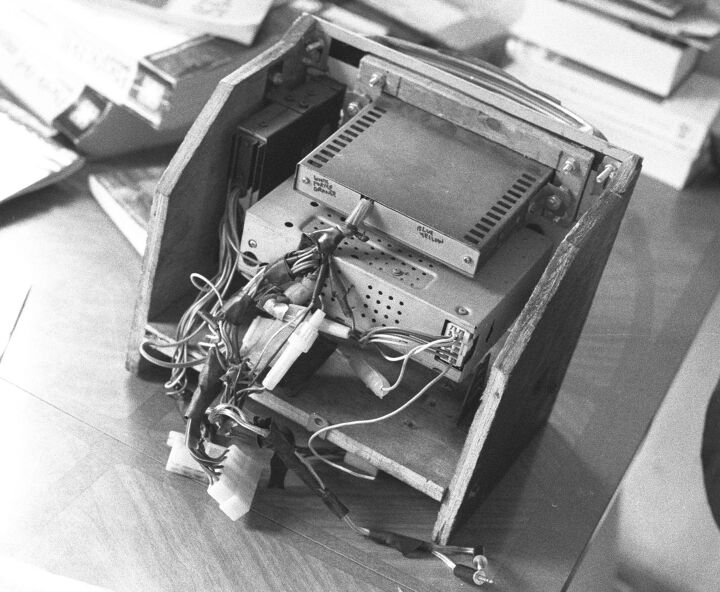

The factory AM radio was long dead, and I needed to listen to my collection of Motörhead and Public Enemy cassettes at all times behind the wheel. So, I broke out the plywood and the jigsaw and made this removable console unit to sit beneath the dash and atop the transmission hump (held in place with a couple of brass deadbolts). With eight junkyard speakers (four in the rear package shelf, two in each front door) driven by a pair of four-channel Brand X equalizer/amplifiers fed by a not-too-terrible Sony cassette deck (veteran of at least three of my previous vehicle dashes by that time), I had serious sound for next to nothing. Because I was parking the car in a lot of sketchy rip-U-off neighborhoods of San Francisco and Oakland at the time, I rigged my semi-unwieldy pull-out stereo with quick-disconnect harness connectors salvaged from junked Corollas. To remove the unit, I just pulled a couple of deadbolts and disconnected four harness connectors; it made for quite a conversation piece when I’d set it on the kitchen table at parties. I wish I had a photo of the front of the unit, but… damn pre-digital photography era once again.

Overall, this setup proved quite reliable, although I had to replace a few of the cheapo gauges over the years. At this point, the only real problems with the car, from a daily-driving perspective, were the four-wheel drum brakes and the lack of a heater. I solved those problems soon enough, as we’ll see in an upcoming episode of this series.

The skills I learned from this project proved useful in later years; when it came time for me to build the instrument panels for the Black Metal V8olvo race car, I was up and running in a hurry.

This setup remains in the car to this day, just awaiting its new owner to fly to California and get behind the wheel. Yes, I mean the legendary donk-racin’ Speedycop.

My 20R-powered ’67 Sprite, which now sits in the Evil Genius Racing on-deck-projects yard awaiting a narrowed RX-7 rear, also benefited from my instrument-panel-creating experience. See, working on Hell Projects pays off! Next up: Disc brakes, Generation X road tripping.

Murilee Martin is the pen name of Phil Greden, a writer who has lived in Minnesota, California, Georgia and (now) Colorado. He has toiled at copywriting, technical writing, junkmail writing, fiction writing and now automotive writing. He has owned many terrible vehicles and some good ones. He spends a great deal of time in self-service junkyards. These days, he writes for publications including Autoweek, Autoblog, Hagerty, The Truth About Cars and Capital One.

More by Murilee Martin

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Spectator Wild to me the US sent like $100B overseas for other peoples wars while we clammer over .1% of that money being used to promote EVs in our country.

- Spectator got a pic of that 27 inch screen? That sounds massive!

- MaintenanceCosts "And with ANY car, always budget for maintenance."The question is whether you have to budget a thousand bucks (or euro) a year, or a quarter of your income.

- FreedMike The NASCAR race was a dandy. That finish…

- EBFlex It’s ironic that the typical low IQ big government simps are all over this yet we’re completely silent when oil companies took massive losses during Covid. Funny how that’s fine but profits aren’t. These people have no idea how business works.

Comments

Join the conversation

Don't even get me started on how much hassle it was to cut the STEEL back deck of my '63 Nova to get those Jensen Triax speaker in there...

Quite impressive! Can't wait for the next write up!