Patent Reveals GM Is Working on a High-compression, Twin-turbocharged, Hybrid Powertrain

General Motors has recently filed a patent that could point to the future of the company’s high-performance offerings, including the C8 Corvette.

After 18 months in review by the United States Patent and Trademark Office, documents published on October 24, 2017, reveal GM has been granted a patent for an internal combustion engine with elevated compression ratio and multi-stage boosting.

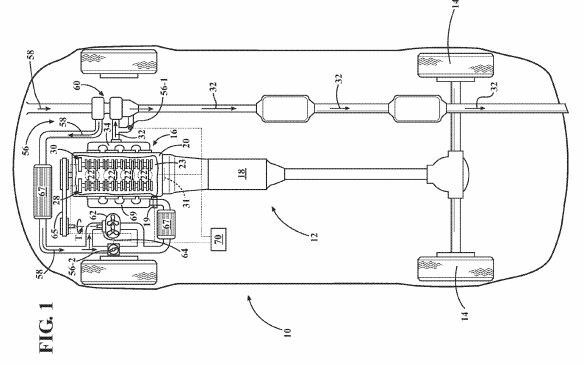

The document describes a propulsion system made up of a high compression internal combustion engine that uses a low-flow supercharger in combination with a high-flow turbocharger, linked to “one or more electric motor/generators.”

It gives us an interesting look at how GM engineers plan to continue producing obscene performance cars like the Corvette ZR1 and Camaro ZL1 1LE in a world of increasingly stringent emission regulations.

The illustrations depict a longitudinally mounted four-cylinder engine, but GM claims the thinking disclosed could be applied to engines with larger cylinder counts as well.

Typically, street legal engines using forced induction operate below a 10.5:1 compression ratio in order to mitigate the effects of pre-detonation. High compression and forced induction don’t usually mix because the extra air-fuel mixture crammed into the cylinder by the turbo or supercharger can ignite prematurely as a result of the elevated cylinder temperatures generated by higher compression ratios.

In order to make high-compression ratios and forced induction viable for an engine that must meet federal requirements, GM is proposing an extreme variation of the Atkinson-cycle – using late intake valve closing to allow some of the air-fuel mixture to escape and eliminate the risk of pre-detonation.

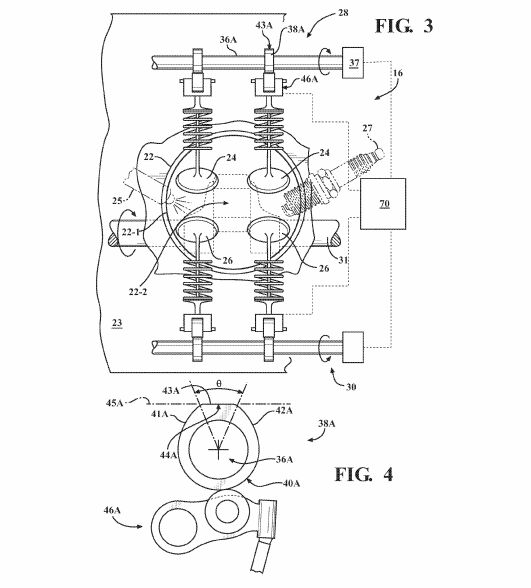

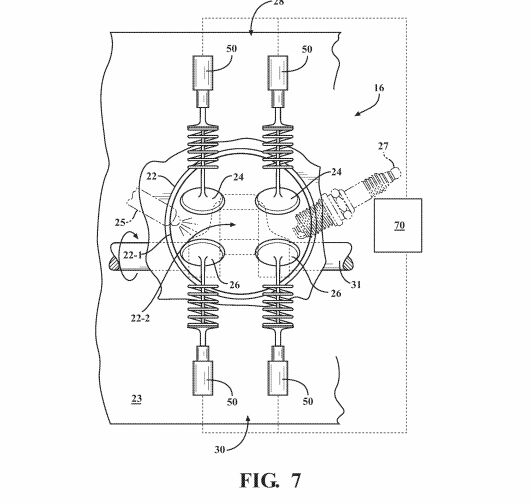

Where GM’s patent differs from other Atkinson-type applications is the length of time the intake valves would be kept dwelling at peak lift. In the document GM proposes two different methods for generating peak lift for an extended period of time – simple cam lobe profiling in combination with a variable-ratio rocker arm between the valve stem and the cam lobe; or an electro-hydraulic actuator which could replace the conventional camshaft.

Using the cam and rocker solution, GM would employ a “generally flat” portion of the cam lobe that would interact with the variable-ratio rocker arms to jam the intake valve open for a slightly extended period of engine rotation.

The rocker arms would include their own rotatable cam-shaped roller, which could alter the duration of peak lift dwell from substantial to insignificant. In another variation, a more traditional cam lobe could interact with a cam follower to achieve the same effect.

Like conventional engines with variable cam and valve technology, the position of the cam and rollers could be changed by high-pressure streams of oil shot by phasers. Using this method, GM claims the intake valves could be kept at peak lift for an extra 20 degrees of cam rotation.

Should GM replace the camshaft with a hydraulic or mechanical actuator, the ECU would offer much greater control over the valvetrain. The document claims peak intake dwell could be achieved for 5-80 degrees of crankshaft rotation, which is just shy of a quarter rotation, or nearly one full cycle.

GM claims using either solution would yield compression ratios for forced induction engines between 11 and 16:1. To put that in perspective, methanol-fueled drag racing engines typically run a 15:1 compression ratio, while Formula 1 cars operate at 17:1. It’s unclear if GM intends to use the system to offer variable compression ratios like other automakers have proposed.

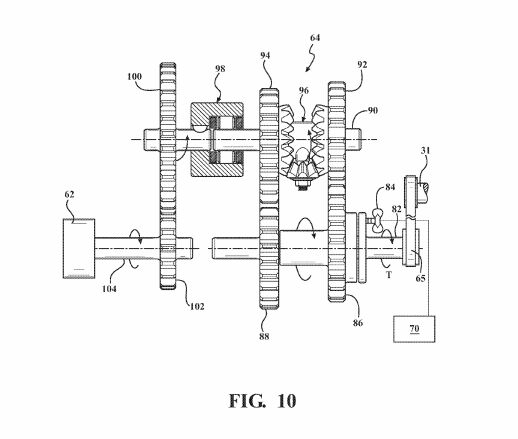

The document also includes new thinking on twincharging and the application of boost pressure. GM says the supercharger could be driven by either the crankshaft or a dedicated electric motor, with the blower’s speed managed by a continuously variable transmission that would control the supercharger independent of engine RPM.

Meaning the CVT could keep the supercharger pegged at peak boost if necessary, or spooled for low-RPM acceleration before the turbocharger clicks on above 3,000 RPM, when enough high-flow exhaust would be available to feed the impeller. The multi-boosted system could be capable of operating sequentially or in tandem based on what the vehicle’s ECU wants, which will, in turn, depend on if it’s been programmed for performance or economy.

It’s unclear how GM plans to apply the thinking delineated in the patent, but considering the high-performance potential of the proposed system, this could be our first inkling of what’s going to motivate the hybridized mid-engine Corvette.

[Images: General Motors, U.S. Patent and Trademark Office]

More by Michael Accardi

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Master Baiter I told my wife that rather than buying my 13YO son a car when he turns 16, we'd be better off just having him take Lyft everywhere he needs to go. She laughed off the idea, but between the cost of insurance and an extra vehicle, I'd wager that Lyft would be a cheaper option, and safer for the kid as well.

- Master Baiter Toyota and Honda have sufficient brand equity and manufacturing expertise that they could switch to producing EVs if and when they determine it's necessary based on market realities. If you know how to build cars, then designing one around an EV drive train is trivial for a company the size of Toyota or Honda. By waiting it out, these companies can take advantage of supply chains being developed around batteries and electric motors, while avoiding short term losses like Ford is experiencing. Regarding hybrids, personally I don't do enough city driving to warrant the expense and complexity of a system essentially designed to recover braking energy.

- Urlik You missed the point. The Feds haven’t changed child labor laws so it is still illegal under Federal law. No state has changed their law so that it goes against a Federal child labor hazardous order like working in a slaughter house either.

- Plaincraig 1975 Mercury Cougar with the 460 four barrel. My dad bought it new and removed all the pollution control stuff and did a lot of upgrades to the engine (450hp). I got to use it from 1986 to 1991 when I got my Eclipse GSX. The payments and insurance for a 3000GT were going to be too much. No tickets no accidents so far in my many years and miles.My sister learned on a 76 LTD with the 350 two barrel then a Ford Escort but she has tickets (speeding but she has contacts so they get dismissed or fine and no points) and accidents (none her fault)

- Namesakeone If I were the parent of a teenage daughter, I would want her in an H1 Hummer. It would be big enough to protect her in a crash, too big for her to afford the fuel (and thus keep her home), big enough to intimidate her in a parallel-parking situation (and thus keep her home), and the transmission tunnel would prevent backseat sex.If I were the parent of a teenage son, I would want him to have, for his first wheeled transportation...a ride-on lawnmower. For obvious reasons.

Comments

Join the conversation

If someone else like the Koenigsegg Free Valve or the Qoros Qamless people decide to give the intake valve(s) an opening profile similar to this, who is going to stop them? A GM lawyer? GM is patenting a particular system and valve lift and duration variability which doesn't seem very novel to me. I've read of the above two small Scandinavian companies doing exactly this, quick open to full lift that is sustained. Or anything in between. So what's new here really? Not much. Typical patent overreach in the claims. Good luck suing someone else who's been at something similar for years. Prior art and all. The physical compression ratio remains the same, the expansion ratio changes as in all Atkinson or Miller cycles, where one can fiddle with the amount of air let in a cylinder and then sometimes some is pushed back into the intake manifold. Or not if one limits intake valve opening timing. If the variable CR is just being quoted because the intake charge varies in mass compared to what a "normal" system would admit at those revs, then a weak case can be made for the nomenclature, but all Atkinson cycles pull that same trick off. There are other ways that maximize volumetric efficiency and expansion ratio like the VW Brudack cycle used on the new Tiguan's 2.0t engine, and Mazda do something not dissimilar on their CX-9 turbo engine but without variable lift except at cold start. Doubt that parallel versus series compression using a supercharger and turbocharger hasn't been tried before. It's that obvious. Volvo uses one or the other on the 316 hp engine; can't be bothered looking up which it is. The only novel thing I see is using a CVT for the supercharger drive. With the new 48V systems the Germans are coming up with to use an electro-turbocharger - Daimler claims 70,000 rpm in 0.30 seconds from stop in the electro-turbo in the new M256 engine, doing it mechanically on the supercharger instead is indeed novel. And that's about it. The 48 volt electric assistant turbo spin up systems will likely win as the technology is virtually off the shelf from Continental now. No mechanical CVT required, thus cheaper.

I read it as a regular powertrain CVT managing the boost - not the blower being spun by a CVT.