#FactoryNews

Rivian Completes First Production Vehicles Intended for Customers

Despite EV startups taking a lot of flak for habitually overpromising, sometimes on a level that approaches criminal fraud, things appear to be going rather well at the Rivian factory. Founder and CEO Robert Joseph “RJ” Scaringe announced that the company started building its very first production units on Tuesday.

With the necessary regulatory certifications in hand, Rivian can now begin delivering vehicles directly to customers and the timing couldn’t be much better. The electric brand had said it was basically done with prototypes and ready to spin up the assembly lines for the final product late last month. While this still placed it a bit behind schedule, the company now says it has all the necessary certifications from the relevant regulatory agencies (NHTSA, EPA, CARB, etc.) and an automobile that’s been federally approved for sale.

Place Your Bets: German Gigafactory Operational By October?

Tesla Gigafactory has been hit with more red tape than a last-minute Christmas present and is reportedly nearing completion. Elon Musk even suggested the facility could be producing vehicles by the end of October. However, some of the language emanating from his recent 0n-site engagement has us wondering what the odds are on that becoming a reality. The facility has already been delayed on more than one occasion by environmental activists and bureaucratic hang-ups. Though it now appears to be within a few weeks of commencing operations, Tesla’s CEO didn’t sound overly optimistic about the target.

On Friday, Musk met with Armin Laschet — Germany’s leading Conservative candidate to succeed Angela Merkel as chancellor — to tour the grounds of Gigafactory Berlin (technically Gruenheide). Though the main event was Elon’s preceding meeting with local Brandenburg officials that have not yet given final approval on the facility, citing ecological concerns.

GM Prioritizing Pickup Production Over Crossovers, Sedans

General Motors will resume full-size pickup assembly next week, leaving its crossovers will have to continue enduring production hang-ups related to the semiconductor shortage. American manufacturers have been absolutely creamed by supply shortages this year and a lack of chips really hurt pickup volumes. We’ve seen a lot of creative solutions, including automakers putting unfinished vehicles on the lot in hopes that they can install the missing hardware later.

But GM’s latest solution involves prioritizing Michigan’s Flint Assembly, Indiana’s Fort Wayne Assembly, Silao Assembly in Mexico — all of which were previously idled or operating on reduced schedules. Unfortunately, that means giving other North American facilities more downtime and, sadly, plenty of it.

Tesla's German Factory Needs Help From Shanghai

Despite achieving a miraculous global expansion in a period where established industrial conglomerates and regulatory hurdles make it nearly impossible for new automakers to persist, Tesla’s German facility is running behind schedule. Production at the Gruenheide plant (aka Giga Berlin or Gigafactory 4) was originally planned to commence this month, with deliveries kicking off shortly thereafter. But those targets have been shifted closer to the end of this year or the more likely scenario of early 2022.

As Tesla would still like to supply the market, its facility in Shanghai will begin shipping vehicles to Europe in August until local production can be achieved. Model Y crossovers will be imported from China until its German site has its assembly lines humming, which has turned out to be a harder task than the automaker anticipated.

Stellantis Plots More Factory Downtime, Ford Loses Tech Chief

Stellantis plans to extend the typical summer downtime at a couple assembly plants while relaunching production at Windsor Assembly next month. The Canadian van factory will be see two shifts returning on July 5th, while its Belvidere Assembly Plant in Illinois and Toluca Assembly Plant in Mexico will be idled due to the ongoing semiconductor shortage. This has become a common tactic within the automotive industry, with our doubting it’ll be the last occasion we’ll be reporting on extended summer vacations.

Meanwhile, Ford Motor Co. appears to have lost its technology chief to Amazon. Ken Washington was hired into Blue Oval after a stint with Lockeed Martin in 2014 and will be leaving the automaker next month to become vice president of software engineering for the tech giant.

Subaru Getting Super Screwed By Semiconductor Shortage

The global semiconductor shortage has been particularly hard on Western automakers, though it’s not been peaches and cream for Asian brands. Following news that Nissan had run into issues resulting in additional downtime this summer, we’ve learned that Subaru is currently operating with a scant, nine-day supply of product and will be required to conduct more plant closures due to a lack of chips.

Having already stalled its Yajima plant on multiple occasions, as well enacting work stoppages at Subaru of Indiana Automotive (its U.S. facility), this is hardly where the brand wanted to find itself going into the warmer months. On Friday, Subaru announced it would be idling two plants in Japan’s Gunma prefecture this July.

Polestar Announces Electric SUV Will Be Made in America

Volvo-owned Polestar has announced that its upcoming “performance SUV” will be manufactured within the United States, starting late in 2022. The model will be assembled alongside other Volvo products at the Swedish company’s facility in South Carolina. It also provides an opportunity for Chinese parent Zhejiang Geely Holdings to make meaningful moves on the North American marketplace and less ammunition for critics to reference the EV-focused Polestar as a foreign brand.

“Polestar 3 will be built in America, for our American customers,” said Polestar CEO Thomas Ingenlath. “I remember the great response when I first shared Polestar’s vision here in the USA and I am proud that our first SUV will be manufactured in South Carolina. From now on, the USA is no longer an export market but a home market.”

Chip Shortage Encourages Nissan to Idle U.S. Facilities Again

Rumor has it that the semiconductor shortage is going to be leaving Nissan facilities operating in North America to contend with a difficult summer. This issue appears to have been largely unavoidable but it’s hardly the position a manufacturer hoping to launch a comeback tour wanted to find itself occupying.

But, before we make this look like some failing on the part of Nissan, let’s take a look down memory lane to see some of the other companies that were negatively impacted by the chip shortage this year.

Report: GM Needs More Manpower, UAW Suggests It Stop Drug Testing

Flint Truck Assembly is the only standing reminder of General Motors’ formerly impressive commitment to Genesee County, Michigan. Other representations include a myriad of crumbling factories that were closed decades ago and the area’s preponderance of vintage, high-mileage Buicks retained out of utility after the employment situation turned sour. Saying that the region has fallen upon hard times would be a grotesque understatement.

But that doesn’t mean there still aren’t still automotive jobs to be had. Despite GM reducing its Flint workforce from roughly 80,000 in the mid-1970s to fewer than 10,000 in 2010, the truck plant is still operational and reportedly looking for 450 temp workers to help fill in scheduling gaps for the 5,100 union-represented staffers it currently employs. Unfortunately, it’s been having trouble finding enough bodies, though the UAW has a solution. It believes that General Motors should stop drug testing, especially now that Michigan has legalized recreational marijuana use.

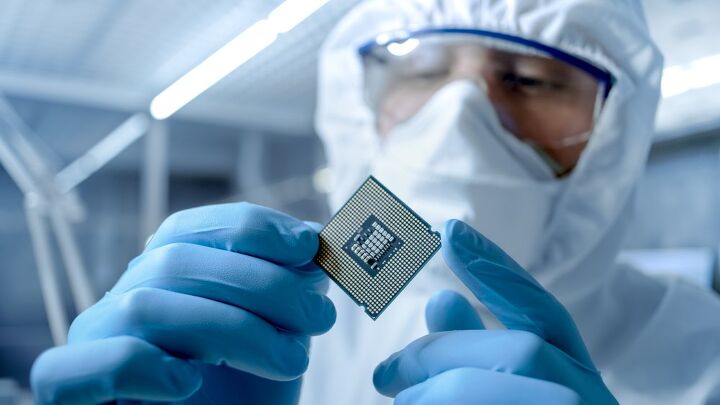

QOTD: Should the U.S. Produce Its Own Semiconductor Chips?

Now that it’s effectively too late to avoid a crisis, the United States has begun asking itself whether or not now is the time to put into motion a plan that will eventually lead to the nation manufacturing its own semiconductor chips. As you’re undoubtedly aware, the automotive sector has taken a beating as Asian-based supply chains are experiencing what can only be described as unprecedented demand. But they aren’t building enough to satisfy everyone and the local markets are taking precedent.

U.S. Commerce Secretary Gina Raimondo proposed a $52-billion solution on Monday that would cram fresh government funds into production and research that could result in seven to 10 new U.S. factories. But that’s just to get the ball rolling on an industry that will take several years to mature, leaving some to wonder whether the country should even bother.

Lordstown Motors Cuts Production Estimates By More Than Half

One of the biggest contributors to EV skepticism are the companies associated with furnishing the technology. While brands like Tesla have unquestionably proven that there’s a market for electric cars, there’s a cadre of startups that seem built on a foundation of falsehoods and do nothing other than vacuum money to feed hypothetical products that never seem to manifest in the physical realm. But the problem is that it’s incredibly difficult to distinguish between them when even Tesla participates in making wild promises it clearly has no intention of keeping and is heavily dependent on regulatory issues favoring EVs — specifically via the sale of carbon credits.

Lordstown Motors has occupied a gray area between the extremes. However, it recently cut this year’s production targets by more than half, warranting some legitimate concern.

Report: Semiconductor Chip Shortage Could Affect 4 Million Vehicles

The semiconductor shortage marches onward with no real end in sight. Supply chains remain a tangled mess following a year of pandemic-related restrictions and demand remains ridiculously high as we unnecessarily network and digitize increasingly more consumer goods (e.g. toothbrushes).

Though this website is really only concerned with the pace of automotive factories — most of which seem operating at the industrial equivalent of driving on the shoulder with the hazards on. The global number of vehicles lost in announced shutdowns and line slowdowns as a result of chip shortages is swiftly closing in on 3 million and estimates have it continuing on unabated for the rest of 2021.

Report: Tesla Won't Be Buying More Land in Shanghai

Tesla has reportedly canceled plans to expand its Shanghai plant. The electric vehicle manufacturer originally intended to make a land purchase and create a global exportation center for its products. But tensions between China and the United States have persisted, making any vehicles shipped to our market substantially less profitable for the company.

Automobiles exported from China are currently subject to a 25-percent tariff issued under the Trump administration as retaliation for the Chinese Communist Party’s heavy restrictions on foreign manufacturers. While Tesla is one of the only companies in existence that isn’t subject to China’s mandatory joint venture, resulting in a factory it wholly owns, the firm would still be subject to tariffs on every vehicle shipped to the U.S. and has recently endured a campaign of negative publicity in the region. China seems suddenly less friendly toward Tesla and it’s responding with the maximum amount of caution.

South Korean Battery Firms Reach Settlement, Georgia Factory Approved

It looks like the White House won’t be needing to take any action in response to the International Trade Commission’s decision on how to handle the feud between South Korea’s LG Chem and SK Innovation. The duo has reached a settlement that would allow the former battery manufacturer to complete assembly on its $2.6-billion plant located in Georgia.

LG alleged that SK had stolen intellectual property and the ITC was backing punitive measures that would have forbade the latter company from importing certain lithium-ion batteries into the United States under a 10-year exclusion order. While exemptions were made for the components necessary to manufacturer them in the country, the arrangement was tied to SK’s existing orders and limited to just 4 years. The settlement gives SK additional leeway and prevents Joe Biden from having to consider the possibility of blocking the ITC decision as a way of maintaining American jobs.

Ford Skipping Summer Shutdowns

Ford will be ignoring the typical two-week summer shutdown this year as a way to make up for production downtime caused by the semiconductor shortage. That’s undoubtedly going to complicate some vacation plans. But Blue Oval has already given loads of workers time off and has more downtime planned through April and now that the necessary factory maintenance can be accomplished while assembly lines are idled during supply chain issues, leaving employees to schedule any time off through their local union.

Recent Comments