"Supplier Bailout" Ends

If there’s a single phrase dominating the imaginations of auto executives right now, it’s the infamous neologism of “too big to fail.” Whether executives justify their obsession with consolidation with their fear of a Chinese planet, efficiency-standard ramp-ups, or mere groupthink, there’s no doubt that consolidation is currently the name of the game. And it should be, not only for these reasons, but also because the last several years have proven that the car game is no industry for small companies. Nothing illustrates this quite like the US government’s “bailout” of auto industry supplier firms, which ended on April Fools Day.

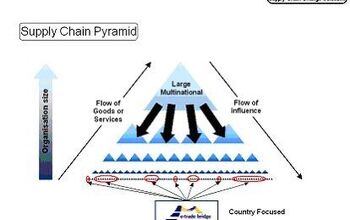

The $3.5b “supplier bailout” came only after GM and Chrysler had been given access to the federal trough, based largely on fears that their failure would put hundreds of small supplier companies out of business in a “cascading bankruptcy” scenario. Ironically, however, supplier aid wasn’t actually given to suppliers at all, let alone the mom and pop shops that form the basis of GM and Chrysler’s emotional appeal for government assistance. Instead, the program gave money to GM and Chrysler to pay back the largest suppliers that the two firms already owed significant amounts of money to, in effect, perpetuating the unsustainable relationships between these firms until private capital became more available. According to a recent GAO repor t:

Treasury had rejected appeals from the auto supply sector for direct aid to assist a broader portion of the supplier industry because, according to Treasury officials, it had become clear that the vast network of suppliers had to engage in a substantial restructuring and capacity reduction to achieve long-term viability.

In other words, the only difference between the bailed-out automakers and their un-bailed-out suppliers was scale. After all, GM and Chrysler were given billions in aid (including this $3.5b supplier debt-enabling slush fund) to restructure and reduce capacity. And their largest suppliers, who were carrying hefty OEM accounts receivable, were able to survive on cash funneled to them through this program. As the Detroit News reports:

According to GM, 74 percent of its 1,300 suppliers were eligible for the program, but only 28 percent of its suppliers received funds under the program.

Nearly half of the $947.8 million in program funds that GM dispersed went to 31 of its top 40 suppliers.

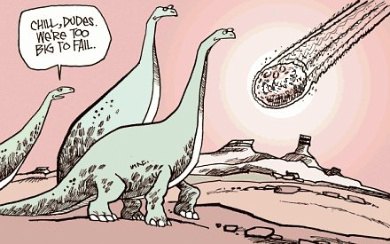

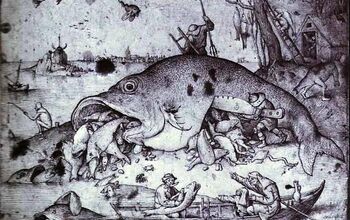

The moral of the story: if your supply firm was big enough to allow GM or Chrysler to carry a balance, you survived. If not, you became just one more bankruptcy in a supplier sector that had already been enduring hundreds of Chapter 11 filings per year before GM and Chrysler ever went a-begging to Washington. Forget all the other motivations for industry consolidation: “too big to fail” is the operating term here. And as the Cretaceous-Tertiary Event proved, bigger isn’t always

More by Edward Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- HotRod Not me personally, but yes - lower prices will dramatically increase the EV's appeal.

- Slavuta "the price isn’t terrible by current EV standards, starting at $47,200"Not terrible for a new Toyota model. But for a Vietnamese no-name, this is terrible.

- Slavuta This is catch22 for me. I would take RAV4 for the powertrain alone. And I wouldn't take it for the same thing. Engines have history of issues and transmission shifts like glass. So, the advantage over hard-working 1.5 is lost.My answer is simple - CX5. This is Japan built, excellent car which has only one shortage - the trunk space.

- Slavuta "Toyota engineers have told us that they intentionally build their powertrains with longevity in mind"Engine is exactly the area where Toyota 4cyl engines had big issues even recently. There was no longevity of any kind. They didn't break, they just consumed so much oil that it was like fueling gasoline and feeding oil every time

- Wjtinfwb Very fortunate so far; the fleet ranges from 2002 to 2023, the most expensive car to maintain we have is our 2020 Acura MDX. One significant issue was taken care of under warranty, otherwise, 6 oil changes at the Acura dealer at $89.95 for full-synthetic and a new set of Michelin Defenders and 4-wheel alignment for 1300. No complaints. a '16 Subaru Crosstrek and '16 Focus ST have each required a new battery, the Ford's was covered under warranty, Subaru's was just under $200. 2 sets of tires on the Focus, 1 set on the Subie. That's it. The Focus has 80k on it and gets synthetic ever 5k at about $90, the Crosstrek is almost identical except I'll run it to 7500 since it's not turbocharged. My '02 V10 Excursion gets one oil change a year, I do it myself for about $30 bucks with Synthetic oil and Motorcraft filter from Wal-Mart for less than $40 bucks. Otherwise it asks for nothing and never has. My new Bronco is still under warranty and has no issues. The local Ford dealer sucks so I do it myself. 6 qts. of full syn, a Motorcraft cartridge filter from Amazon. Total cost about $55 bucks. Takes me 45 minutes. All in I spend about $400/yr. maintaining cars not including tires. The Excursion will likely need some front end work this year, I've set aside a thousand bucks for that. A lot less expensive than when our fleet was smaller but all German.

Comments

Join the conversation

This was no bailout. As corporate staff sales and market monitoring manager (basically an internal consultant for all kinds of wierd stuff) for a billion-dollar european Tier 1, I was asked by our board, at the last minute (17:00 on a Friday evening), to take over the issue from the formerly responsible employee, and to make a recommendation as to whether we should participate in this initiative. In our case, we had no significant GM business, but a large Chrysler business. Our board was looking for any solution that would provide a measure of coverage for our receivables (we are not the kind of company that at our level has to go to the markets to secure capital, this is handled by the corporate finance departement of our parent company; so this means we would not have participated in the program as a way of securing loans with receivables as many smaller companies do.) Several hours later, after reading through 2" of program documents and internal correspondence, I came to the conclusion that this program, due to the consditions imposed by Chrysler upon its supply base (essentially having to take and maintain a 5% price cut, and agree to further stretching payment terms, both until the undefined end of the program) made it an unattractive deal (and, in other ways, made the supplier even more dependent upon the OEM, and limited the freedom of the Tier-1 to quit the business if the OEM didn't take proper steps to ensure the supplier recover monies owed to it by the OEM.) So, my memo written in the wee hours of the morning was to skip enrollment in the program. Up until that point, the convention wisdom was that it would be good to enroll in the program, but come the following Monday, that was changed by my memo. Noboby was really sure what would happe if the OEM's entered bankruptcy protection, or if they would emerge, or to what extent a Tier-1 would be able to recover monies owed via the bankruptcy process. In the end, I didn't get burned by events and my recommendation looked pretty good given all the administrative headaches gained by suppliers having to work to get on track with the OEM and Citibank (who administered the programme.) Chrysler filed for BK and in the process, they ensured that their supply base received 100% of receivables owed (this was a rather unusual, but necessary, step taken to ensure Chrysler's supply base didn't go illiquid before Chrysler could emerge from BK. This was also used by Chrysler as a big lever to get Tier-1s to accept Chrysler's new contract conditions.) We, as opposed to many other Tier-1's were lucky, I had seen Chrysler's BK coming in 3Q08 and beat the drum for our company to take some necessary steps to position for a Chrysler BK, when this finally happened in Feb 09, we were then positioned to be able to define the terms for continuing business with Chrysler, and of the post-Ch-11 contract relationship. So we didn't have the urgent need to jump into this program. This program was not free, and it was funded by the supplier cutting prices by 3% or 5% (depending on which of two options the supplier selected), and for some suppliers, who could afford the price cut, so as to ensure they would be able to get their receivables (and keep their bankers happy) during a very uncertain time, the program may have been a good deal. (Keep in mind, no one had been able to get receivables insurance from mid-2008, and this impacted the ability of some suppliers to secure funding for CapInv.) Paul, I was casually tracking supplier bankruptcies beginning in 2007, and watching with interest and concern as these increased thru 2008 and 2009... Perhaps the remark of "hundreds" of suppliers having gone bankrupt includes Tier-2 and -3 suppliers, but I am unaware of "hundreds" (more like dozens) of suppliers having gone BK... I'd be interested to see the references that support this claim.

As we continue to feel the effects of "too big to fail" we have determined to solve the problem by having the small firms that were allowed to fail be absorbed by those that were brought down by their own Brobdingnagian nature. Tomorrow: Save your village by burning it to the ground.