Williams Engineering and Italdesign Launching Joint EV Platform

Williams Advanced Engineering is teaming up with Italdesign to establish another electric vehicle platform targeting the wealthy — or an “upper-premium EV production solution,” according to those responsible for its development.

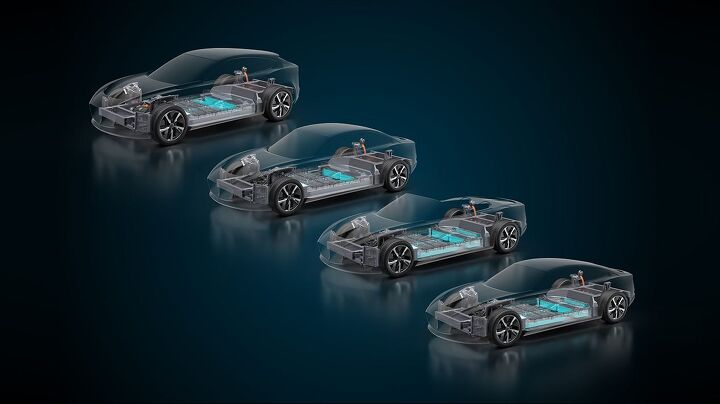

Dubbed the EVX modular electric platform, the architecture uses large structural batteries and an abundance of recycled composites mixed in with lightweight aluminum. They should also be pretty chic, considering the parties involved. Williams exists specifically to adapt technologies utilized by its Formula 1 team for commercial applications while Italdesign is probably the most famous automotive design studio in automotive history.

Everything starts with WAE’s chassis, which can accommodate power packs between 104 and 120 kWh with the ability to discharge over 1000 kW (roughly 1,300 mechanical horsepower). Williams is leaning on its performance expertise to sell the concept, though it claims that will translate to an enviable range. On the outer limits, the manufacturer said cars could be equipped with an expanded 160-kWh unit that could deliver over 621 miles on a single charge. While not a fully-fledged battery supplier, WAE has been supplying them for the FIA Formula E World Championship for years. It does the same for ETCR (electric touring cars) and Extreme-E (off-roaders) — which bodes well for the EVX.

Platforms can be scaled for automobiles using wheelbases between 114 and 122 inches and aren’t picky about body style. Williams said it was excited to see an array of high-end vehicles using its skeleton, noting that the platform could handle both rear and four-wheel drive. Mixing composites with aluminum helps minimize weight and lets WAE brag about using recycled materials. But it’s also supposed to set a new standard for static and torsional stiffness — though the manufacturer did not divulge what materials were used beyond the ever-popular carbon.

The structural battery plays a large role here as well. In addition to keeping a low center of gravity, its case attaches directly to the chassis and has reinforced areas at key stress points. This makes for a more rigid structure before bodywork has even been considered, which makes Italdesign’s job that much easier. Williams’ even suggested that it would allow the design firm to have more freedom in certain instances, by not needing to add as much strength to the bodywork.

After WAE wraps on its duties, Italdesign becomes responsible for taking the electric skateboard and finishing it up for whichever automotive brand placed the order. While the bodywork will be done by the studio, it will need to be approved by whatever company placed the order and include their branded safety systems and user interface.

“We are extremely glad and thankful of the chance to cooperate with Williams Advanced Engineering,” Antonio Casu, CTO at Italdesign, stated in the release. “With 53 years of experience in design and engineering development, our role in the partnership will be to advance the rolling chassis developed by WAE to the complete platform and shape it according to the vehicle body style, architecture and contents defined with customers. Over the past five decades we have developed skills and experiences in turnkey projects, meeting our customers’ needs, whether international OEMs or new born start-ups.”

“We aim to develop vehicle architectures in the GT, Sedan, Crossover and Convertible markets, fully customisable [sic] inside and outside. We are targeting business cases that will cover different production volumes from an Ultra Limited Series up to 10,000 units a year, 500 of which can be built by Italdesign at our facilities in Turin.”

[Image: Williams Advanced Engineering]

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- EBFlex No they shouldn’t. It would be signing their death warrant. The UAW is steadfast in moving as much production out of this country as possible

- Groza George The South is one of the few places in the U.S. where we still build cars. Unionizing Southern factories will speed up the move to Mexico.

- FreedMike I'd say that question is up to the southern auto workers. If I were in their shoes, I probably wouldn't if the wages/benefits were at at some kind of parity with unionized shops. But let's be clear here: the only thing keeping those wages/benefits at par IS the threat of unionization.

- 1995 SC So if they vote it down, the UAW gets to keep trying. Is there a means for a UAW factory to decide they no longer wish to be represented and vote the union out?

- Lorenzo The Longshoreman/philosopher Eri Hoffer postulated "Every great cause begins as a movement, becomes a business, and ends up as a racket." That pretty much describes the progression of the United Auto Workers since World War II, so if THEY are the union, the answer is 'no'.

Comments

Join the conversation

In short, WAE is going to develop an EV platform, and Italdesign will build bodies for low-volume mfrs to attach to the WAE foundation. This sounds like a very expensive kit car, with 3 significant mfrs involved. Who do I call for service? Where does Williams think it can source so many batteries? I love the hand-drawn pencil designing - those shots appeal to people who don't know how design is done today. Could they have added more buzzwords to the video? That 621 miles range is certainly a WLTP estimate, so figure it'll be more like 525 miles. With a 160 kWh battery, that's about 3.2 mi/kWh - not terrible considering the performance they could provide. Maybe Lotus should talk to these guys instead of developing their own EVs.

Nice writeup, Matt. - "Mixing composites with aluminum helps minimize weight and lets WAE brag about using recycled materials..." - "set a new standard for static and torsional stiffness" - "The structural battery plays a large role here as well." This is impressive stuff (to me). Allow me to clarify: In a world where Ford's product portfolio bears remarkable resemblance to a progressive collapse [of a building or bridge], this kind of clean-sheet approach is impressive. (And separating the development of the pretty parts from the development of the functional parts is smart.)