What's in the Box?! - With GMC's CarbonPro Pickup Bed, Plenty

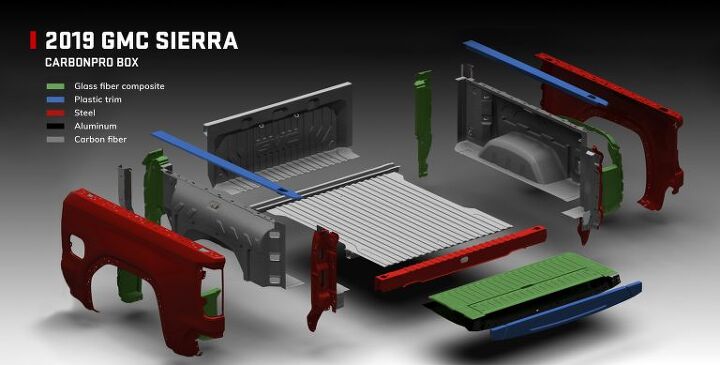

GMC unveiled the 2019 GMC Sierra amid great pomp and circumstance on March 1st. Much of the buzz surrounding the new truck focused on new features like a multi-function tailgate and comprehensive towing suite. One of the new features, CarbonPro, is the industry’s first carbon fiber pickup box. Duncan Aldred, GMC’s Global Vice President, went as far as saying, “In 116 years of making GMC pickup trucks, our industry-first carbon fiber box is the toughest and most durable pickup box we have ever made.”

While we have little reason to question that statement, it gives the impression that this pickup box is made out of supercars and iPhone cases. In reality, it’s chopped up carbon fiber in a nylon plastic resin. After talking to GMC and the supplier that builds the CarbonPro box, we’ve this product does indeed have some important advancements. At the same time, it is also shares some similarities with the pickup boxes found on the Toyota Tacoma and Honda Ridgeline.

Following a similar plan as Toyota and Honda isn’t a bad idea. Both the Tacoma and Ridgeline have durable beds that are lighter than the steel competition. The Detroit Three aren’t blind to that fact.

Ford and GM actually made composite pickup boxes before Honda or Toyota. Ford’s Explorer SporTrac had a four-foot composite bed. Meanwhile, GM had the first full-size truck with a composite bed in 2001. Unfortunately for the future of composite beds, the Silverado and Sierra’s Pro-Tec box, an $850 option, had a take rate of just 10 percent of what GM expected. Sales performance was so poor that it took General Motors over 15 years to introduce another composite box.

This leads us to GMC’s new CarbonPro pickup box. Work on the box started a few years ago as a global development project with Teijin Automotive. GM had engineers co-locate at the Teijin facility in Auburn Hills, Michigan, to create a collaborative product development cycle. At first, joint development work focused on how to design and process the new material; co-development steps included modeling techniques, material validation, manufacturing strategies, and manufacturing processes.

In 2017, Teijin acquired Continental Structural Plastics (CSP). This gave Teijin and GM the materials and manufacturing capability to build the product. CSP had been honing its manufacturing expertise of composite products by making the boxes for the Honda Ridgeline and Toyota Tacoma, as well as hardtops for the Jeep Wrangler and other auto industry composite products.

The end result of the collaboration is a carbon fiber-reinforced plastic box that will be molded in the U.S. and made via a process Teijin calls Sereebo. It is the world’s first mass-production technology for thermoplastic carbon fiber-reinforced polymer. Teijin claims it improves production efficiency by significantly reducing molding time while still yeilding a durable product.

The CarbonPro box uses a chopped 1-inch carbon-fiber thread. The carbon fiber is reinforced with nylon plastic resin sheets, then molded to allow the carbon fiber to bond with the plastic. The process happens in minutes. It’s not a pure carbon fiber weave like pieces of the Lexus LFA. CSP and Teijin are not weaving these beds in giant carbon fiber looms; rather, the molding process is similar to how other composite truck beds are made.

CSP plans to mold the box at its facility in Huntington, Indiana. The 340,000 square-foot factory opened in 2010 and employs around 350 people. It is also less than 30 minutes from GM’s Fort Wayne Truck Plant.

The CarbonPro replaces the standard steel box inner with a lightweight, purpose-designed material that supposedly offers “exceptional” impact resistance, as well as strength and durability. GMC claims the box has significantly stronger material properties that any other composite box on the market. It also estimates the CarbonPro box is 40 percent lighter than steel. Competitors’ composite boxes are only 10 percent lighter than steel, the automaker claims.

Taking the pickup rivalry even further, GMC says traditional “sheet molded composite” — the material used in competitors’ boxes — “would not have met our full-sized truck structural requirements or saved as much mass.” Weight loss, compared to a standard Sierra steel bed, stands at 62 pounds (more, if you included the weight of a spray-on or drop-in liner).

While all the materials underwent durability testing during the co-development process, GM did some unique testing on its own. According to CSP, “Engineers challenged the box’s durability with new creative tests that included dropping 30 Bobcat loads (of) materials including large gravel, crushed concrete and Belgian blocks, as well as the loading in and out of studded snowmobiles.” These tests are what led the automaker to declare it as “the toughest and most durable pickup box we have ever made.”

So far, GMC has only announced that the box will have late availability on the 2019 GMC Sierra Denali. The company wouldn’t comment on future availability on other products or Sierra trims. At this point, it appears there is a future for CarbonPro. There’s already a similar product in use on other trucks, there continues to be an industry-wide quest to save weight, and GMC is marketing this bed aggressively.

But questions about the viability of this product remain. The biggest concern is price. So far, GMC isn’t talking price. In communications with TTAC, CSP did mention this product being affordable. However, without actual numbers, it is difficult to define what constitutes “affordable.” It will also be interesting to see if GM can use this material on other products. The automaker’s partner already makes a large number of sheet molded composite parts for other manufacturers, and there’s the possibility GM can expand on the lightness and strength of the material.

Since the CarbonPro box is only available on the Sierra Denali, sales will be limited —expanding the box to other GMC and Chevrolet models would allow GM to spread out the costs, but if the price is too high, the option will go unordered.

In the past, GM introduced a number of new truck features that never caught on. Quadrasteer, the Pro-Tec bed, Two-Mode Hybrid, and the GMC Envoy XUT were all interesting ideas doomed by price or marketing. We’ll soon see if CarbonPro joins those failed attempts, or if it forces FCA and Ford to develop new pickup boxes of their own.

[Images: Adam Tonge/TTAC, General Motors]

More by Adam Tonge

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Fahrvergnugen cannot remember the last time i cared about a new bmw.

- Analoggrotto More useless articles.

- Spamvw Did clears to my '02 Jetta front markers in '02. Had to change the lamps to Amber. Looked a lot better on the grey wagon.I'm guessing smoked is illegal as it won't reflect anymore. But don't say anything about my E-codes, and I won't say anything about your smoked markers.

- Theflyersfan OK, I'm going to stretch the words "positive change" to the breaking point here, but there might be some positive change going on with the beaver grille here. This picture was at Car and Driver. You'll notice that the grille now dives into a larger lower air intake instead of really standing out in a sea of plastic. In darker colors like this blue, it somewhat conceals the absolute obscene amount of real estate this unneeded monstrosity of a failed styling attempt takes up. The Euro front plate might be hiding some sins as well. You be the judge.

- Theflyersfan I know given the body style they'll sell dozens, but for those of us who grew up wanting a nice Prelude Si with 4WS but our student budgets said no way, it'd be interesting to see if Honda can persuade GenX-ers to open their wallets for one. Civic Type-R powertrain in a coupe body style? Mild hybrid if they have to? The holy grail will still be if Honda gives the ultimate middle finger towards all things EV and hybrid, hides a few engineers in the basement away from spy cameras and leaks, comes up with a limited run of 9,000 rpm engines and gives us the last gasp of the S2000 once again. A send off to remind us of when once they screamed before everything sounds like a whirring appliance.

Comments

Join the conversation

This bed reminds me of those fibreglass swimming pools. A friend of the family owned a swimming manufacturing company and he produced fibreglass pools. It was fascinating to watch. A gun was used that feed the fibre and cut it into 2" lengths and another part of the gun sprayed the epoxy resin. This kind of technology has been around since the 50s and has been modernised by GM. Unless robotics are used extensively I can't see this tub being viable, it's might just be a marketing push.

So, this is so great the mining industry has not adopted this? You would think the agri, construction, etc industries would already be applying this tech. So, why? Hmmm??