Nissan Mulls Extra U.S Manufacturing Capacity

Earlier this year, the big bosses at Nissan expressed their desire to grab a full 5 percent of pickup truck market share in the United States. However, chasing arbitrary targets has now fallen in favor of smart growth.

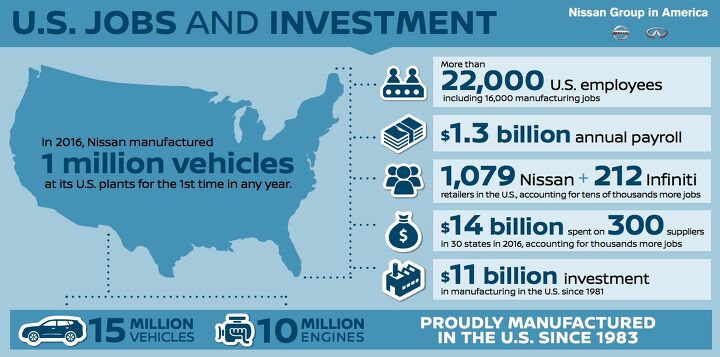

Still, lighting a fire under the brand seems to have worked, with Nissan moving nearly 1.5 million units in 2016, almost a million more annual sales than 15 years ago. With those numbers in mind, the company is acknowledging it’ll soon need a new assembly plant in America.

According to the Japan Times, Jose Munoz, chairman of Nissan North America since 2014, stated, “At some point, we may need it,” referring to additional U.S. production capacity. There’s an excellent chance that any extra capacity would have to come from a new facility, since the plants in Tennessee and Mississippi are currently running at capacity.

The two Nissan assembly facilities in America crank out a bevy of high-volume products. In addition to a couple of other models, the Tennessee plant makes the strong selling Rogue and three-row Pathfinder. In Mississippi, Nissan hosts Titan production, along with that of the Frontier and Murano. That facility has an annual production capacity of 450,000 vehicles, and Nissan’s Mississippi workforce has assembled more than three million vehicles since opening the site in 2003. The Tennessee plant employs 8,400 workers and has an annual capacity of 640,000 vehicles. (The Altima and new Leaf are built stateside as well.)

Going forward, Nissan has committed to building the next-gen Frontier at the same plant where the present truck is being assembled, meaning that any new production will likely add to, not replace, current manufacturing numbers in America. The Mississippi plant employs more than 6,000 workers and, according to a 2016 study by Mississippi State University, the facility has generated 25,000 direct and indirect jobs statewide. Numbers such as these would no doubt be welcome in any manufacturing town across America.

Nissan sold its first automobile in the U.S. in 1958, with U.S. manufacturing starting in June of 1983 as a white Nissan pickup truck rolled off the assembly line at a brand new plant in Tennessee. Now, Nissan has U.S. manufacturing facilities capable of producing 1.14 million vehicles and 1.5 million engines annually. A new facility would only add to those totals.

Now, I’m posting pictures of the ’97 Pathfinder and Frontier because a) they’re wonderful and b) Nissan has an archive of official photos stretching back to 1997. My productivity may suffer for the next 30 minutes.

[Images: Nissan]

Matthew buys, sells, fixes, & races cars. As a human index of auto & auction knowledge, he is fond of making money and offering loud opinions.

More by Matthew Guy

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Rochester I'd rather have a slow-as-mud Plymouth Prowler than this thing. At least the Prowler looked cool.

- Kcflyer Don't understand the appeal of this engine combo at all.

- Dave M. This and the HHR were GM's "retro" failures. Not sure what they were smoking....

- Kcflyer Sorry to see it go. The interior design and color options in particular are rare in the industry

- Wolfwagen Here is my stable. not great not bad I try to do as much as possible. I work for an Aftermarket automotive parts company so I can get most parts at a discount.i try to do as much of my own work as possible. My wife hates that I spend time and money fixing the vehicles but she doesn't want car payments either so...2019 VW Atlas 50K (wife's) Only issues so far were Brakes and normal maintenance.A Bad Cat Converter which was covered and a replacement of the rear bank head gasket which was a manufacturing defect due to improper torquing at the factory. All under warranty2003 Saab 9-5 Arc Wagon (my DD) 116 K picked up used last year. Replaced Struts, brakes, hatch struts, motor mounts, D/S swaybar link, Timing belt, water pump and thermostat Power steering pump Fuel pump, Both Front window regular rollers, Heater core and cabin air filter. Oil and transmission changes. Love the car but Saab/GM packaging is a nightmare.2005 Cadillac Deville (former DD now Son # 1 DD) picked up used 5 years ago with only 47K now 83K Plugs, coils, P/s pump, Water pump, hoses, P/S lines (mechanic job) evap valve, brakes, Front brake calipers and rear brake calipers. Currently has oil pan gasket leak - looking to have a mechanic do that2009 Mini Cooper (Daughters dd)picked up 2 years ago 67K Brakes and thermostat house to clear check engine light2001 Mazda Tribue (Son#2 dd) 106K picked last summer after he severely damaged a 2004 Hyundai accent. Oil changes

Comments

Join the conversation

He's flooding the market w/ lower level stuff because he knows some buy purely on price. There's Toyota, Honda and Mazda and then there's Nissan, below Hyundai and Kia.

Mitsubishi Normal Illinois Assembly plant would have been inexpensive and appropriate to expand Nissan manufacturing. Rivian Automotive purchased it. Perhaps Nissan-Mitsubishi could buy it back.