This is How the Nissan Micra Cup Racecar is Built for $20,000

When the Nissan Micra Cup series was announced in late 2014, there was one main goal: be the most affordable, semi-professional racing series in Canada.

In order to achieve that goal, everything about the series needed to be cost-effective. All races were scheduled in Quebec, where the majority of competitors reside, and tires and brakes had to wear in a predictable manner so as not to “fall off” during race weekends. However, the difficult part was building a racing car to a price — $20,000 CAD, or $15,225 USD at today’s exchange rates, to be exact — so that racers could either pony up the personal funds to buy it themselves or more easily woo sponsors to make their racing dreams come true.

During the planning phase of the series, Nissan Canada and series promoter JD Motorsport tapped racing car builder Motorsports In Action of St-Eustache, Quebec to build the pint-sized racers. MIA, which is located in an indescript row of commercial units racing at Autodrome St-Eustache about 40 minutes northwest of Montreal, fabricates and preps vehicles for varying types of racing series and prides itself on build quality. However, as they say, “Good, Fast, Cheap. Pick Two,” it’s much easier to build a racing car with a high-dollar budget than it is to put together an economical package like the one requested for Micra Cup.

Thankfully, due to MIA’s combined knowledge and ingenuity, racers get a decent chunk of all three. And MIA’s Carl Hermez gave us a tour to show us exactly how they do it.

For those of you who don’t know already, the Micra Cup is a single-model spec series where drivers campaign these specifically prepped Nissan Micras built by MIA. The series just wrapped up its inaugural season during the Fall Classic at Mt-Tremblant. Next year, the season will be expanding its venues to Ontario and growing its schedule from six race weekends to eight.

The organizers must be doing something right if this race series is succeeding where so many others have failed.

Back at MIA’s shop after the final round of the series, a few cars eagerly awaited repairs. MIA offers race support and an arrive-and-drive rental program for those who want to get into the series but don’t necessarily have the capital to buy a car right away.

To build the cars, MIA starts with a bone stock Micra S, which costs them $11,000 after PDI and tax, leaving only $9,000 to work with to convert the subcompact into a racecar.

“Making the project happen within the guidelines was tricky to say the least,” Hermez said during our visit. “When I first started this program, there was — and still is — nothing on these cars to prepare them for racing. There is no bolt-in roll cages available, no cold air intake. Nothing. There’s nothing available on the market. Everything was designed and built in-house.”

On top of it all, MIA needs to complete the entire build in 25 hours for it to be financially viable, which means the order in which they install parts is vital. In comparison, Hermez said, one of their one-off builds — like an Audi R8 — can take anywhere between 500 and 1,000 hours to complete.

Before those parts can be installed, the cars need to be gutted of their interiors. As soon as that’s complete, the airbox is removed and a fire suppression system is installed.

The fire system is a semi-automatic, two-head system. One of the heads is located under the hood. The other is, well, aimed directly at your gentleman or lady bits.

“You definitely don’t want to get sprayed in the face because then you can’t see,” explained Hermez.

The tank holds 1.25 kilograms of a water-based, AFFF solution that’s released at the pull of a lever. The whole system costs about $200. While MIA is installing it, they install the cut-off switch (and its associated wiring) and the race pedals since they are working in that area of the car anyway.

Next comes the hood pins, front tow hook and the cold air intake that they fabricate in-house.

“Hood pins are never simple,” said Hermez. “Getting the holes to lineup is always a pain.”

The cold air intake also provides its own challenges. The Micra racecar still uses a mass airflow sensor, which Hermez said “is not a very accurate way to determine fuel delivery,” so it needs to be accounted for in the design of the cold air intake. Also, all the diameters are exact so the car doesn’t run rich or lean.

The cold air intake, since it is made in-house, is another cost savings opportunity for MIA since they don’t need to farm out the work at a higher cost to account for someone else’s profit margin.

The steering hub is installed next while holes are drilled for the safety harness nut plates. The harness eye-bolts are installed immediately after.

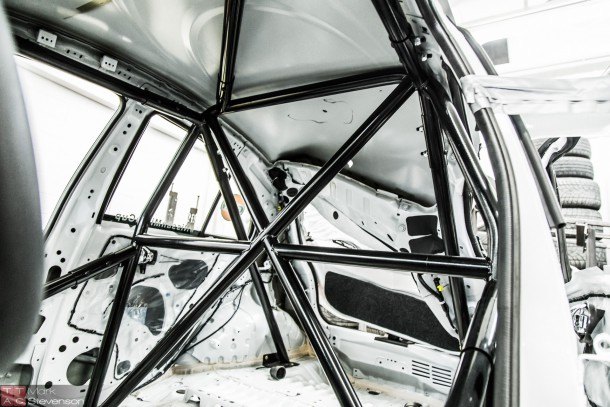

The largest piece — the in-house developed, bolt-in roll cage — is assembled and installed next. MIA farms out bending the individual pieces of the cage, but assembles them on an on-site jig.

And they’re damn strong, as evidenced by a recently wrecked Micra sitting near the jig.

The car was an absolute disaster on the outside. Not a single panel seemed untouched during this Micra’s crash.

The inside of the car was a different story. Not a single section of the roll cage had given way.

“I have never seen a bolt-in cage fit as tightly as this one. A tight fitting cage is everything in terms of its capacity to hold up. Welding them inside the car was not an option because we don’t paint inside the cars,” Hermez said.

However, it wasn’t necessarily the cage itself Hermez was proud of, but the jig to build them. He was quoted $50,000 by a fabricator to make a jig — so he decided to build it himself instead.

“I wasn’t going to spend $50,000 for that!”

Once the cage is in, a false floor is installed as the driver’s seat is much lower than stock and to smooth it out for safety reasons. It also provides the driver a dead pedal. The floor is manufactured off-site, but designed by MIA.

The spare tire is removed and a plug used to fill the spare tire bolt hole before the entire exhaust system is replaced, another part that was developed in house. MIA makes everything between the end of the downpipe and the rear of the car, excluding the muffler.

Since they are already under the car, brakes, brake lines, suspension and camber kit are either replaced or installed. Better performing front brake pads are added to bring the Micra to a stop in a hurry (and they work very well, I found out later). The rear brakes aren’t touched, instead relying on the stock drum setup.

An oil change is performed along with an initial alignment. Door panels are installed, along with the seat, roll cage padding, steering wheel, harness and window net.

And then it’s done. Sometimes.

For racers wanting to get data from their runs, MIA will install an optional AiM Sports MXL2 data acquisition system for about $4,200, ready to go.

So, do you want a piece of this for yourself but don’t want to come to Canada to race it? You might be in luck, but it won’t be $20,000.

“The cars could be Spec B legal with a couple modifications. I’ve been asked by one of our suppliers to prepare a B Spec package, but it will probably cost a bit more than the package for Micra Cup.”

And it isn’t just Americans that could possibly enjoy the cheap fun of Micra Cup in the future.

“I had an organization call me from Columbia that was interested in roll cages.”

More by Mark Stevenson

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- SCE to AUX Range only matters if you need more of it - just like towing capacity in trucks.I have a short-range EV and still manage to put 1000 miles/month on it, because the car is perfectly suited to my use case.There is no such thing as one-size-fits all with vehicles.

- Doug brockman There will be many many people living in apartments without dedicated charging facilities in future who will need personal vehicles to get to work and school and for whom mass transit will be an annoying inconvenience

- Jeff Self driving cars are not ready for prime time.

- Lichtronamo Watch as the non-us based automakers shift more production to Mexico in the future.

- 28-Cars-Later " Electrek recently dug around in Tesla’s online parts catalog and found that the windshield costs a whopping $1,900 to replace.To be fair, that’s around what a Mercedes S-Class or Rivian windshield costs, but the Tesla’s glass is unique because of its shape. It’s also worth noting that most insurance plans have glass replacement options that can make the repair a low- or zero-cost issue. "Now I understand why my insurance is so high despite no claims for years and about 7,500 annual miles between three cars.

Comments

Join the conversation

I'm not that into racing and I really enjoyed this. Great reporting.

Thank you for this. I always wanted get involved with racing, but nothing happening locally.