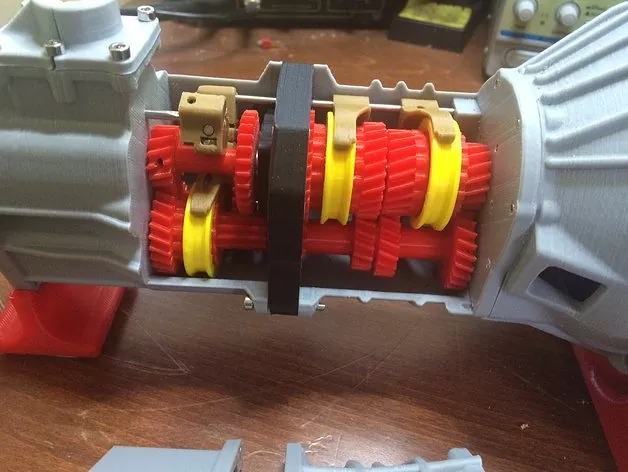

Make Your Own Toyota Transmission At Home (Kind Of)

“The transmission works exactly like most manual transmissions found in any car or truck,” explained Harrell. “However, I can barely explain how it works. It’s fairly hard to grasp unless you assemble one or see an animation of one opened up.”

Last year, I wrote Concours d’Angst as a vision of what small-scale manufacturing might bring to the automotive enthusiast landscape. While I was busy imagining the future, however, someone else was busy making it.

It’s a 3-D printed Toyota transmission made of plastic, for use with a similarly small-scale Toyota 22R engine. You can see it work here:

Obviously, this is neither full-sized nor ready to install in any engine of any type. What makes it important is that it was reverse-engineered by someone who was in no way involved with Toyota, or even with transmissions. As 3-D printing transcends technical limitations and becomes a lingua franca for small-scale fabrication of all types, it will become possible for hobbyists to immediately produce full-sized steel transmissions and other complex parts themselves. It will also become commonplace for those designs to be shared. Imagine a world where you could obtain almost any out-of-stock part for any car through this process, and you’ll see the possibilities.

There will be problems of course — how will you be able to be absolutely sure that the transmission in that hundred-year-old ’77 Celica you just paid two million New Dollars for was machined from tool-grade steel? — but those problems will also be solved as time goes on.

Now, if you’ll excuse me, I’m going to wait for somebody to build me a new four-speed 1990 Fox.

More by Jack Baruth

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jkross22 When I think about products that I buy that are of the highest quality or are of great value, I have no idea if they are made as a whole or in parts by unionized employees. As a customer, that's really all I care about. When I think about services I receive from unionized and non-unionized employees, it varies from C- to F levels of service. Will unionizing make the cars better or worse?

- Namesakeone I think it's the age old conundrum: Every company (or industry) wants every other one to pay its workers well; well-paid workers make great customers. But nobody wants to pay their own workers well; that would eat into profits. So instead of what Henry Ford (the first) did over a century ago, we will have a lot of companies copying Nike in the 1980s: third-world employees (with a few highly-paid celebrity athlete endorsers) selling overpriced products to upper-middle-class Americans (with a few urban street youths willing to literally kill for that product), until there are no more upper-middle-class Americans left.

- ToolGuy I was challenged by Tim's incisive opinion, but thankfully Jeff's multiple vanilla truisms have set me straight. Or something. 😉

- ChristianWimmer The body kit modifications ruined it for me.

- ToolGuy "I have my stance -- I won't prejudice the commentariat by sharing it."• Like Tim, I have my opinion and it is perfect and above reproach (as long as I keep it to myself). I would hate to share it with the world and risk having someone critique it. LOL.

Comments

Join the conversation

The main thing with 3-D printing is that it changes the economics for producing one-off or small runs of things. It's not going to cause factories to disappear and people to have cars automatically assembled in their garages, anymore than CNC milling did. It will, though, revolutionize the aftermarket in both underhood parts and interior/exterior bling. I want one of those model transmissions...

3D Printing has changed the face of car manufacturing.