Swiss Environmental Study Finds EV Battery Production Impacts Outweighed By Operation Impacts

What about battery production? It’s one of the most popular criticisms of the green halo surrounding battery-electric vehicles, and one that’s widely circulated in anti-EV circles. Battery production, it is argued, requires the mining, transportation and processing of minerals which puts EVs at an environmental disadvantage compared to ICE vehicles. Needless to say, quantifying the impacts of ICE and electric drivetrain production is extremely difficult, due to the complexity and global supply chains required to produce both (not to mention the inherent difficulty of quantifying environmental impacts). But a study by the Swiss Federal Laboratories for Materials Science and Technology [via Green Car Congress] took on just that question, and indicates that

the impact of a Li-ion battery used in BEVs for transport service is relatively small. In contrast, it is the operation phase that remains the dominant contributor to the environmental burden caused by transport service as long as the electricity for the BEV is not produced by renewable hydropower.

Impacts for the study are measured in Global Warming Potential (GWP), and Cumulative Energy Demand (CED), which were

chosen for their broad acceptance and relevance in decision making.

Abiotic depletion potential (ADP) was also used to track potential impacts on mineral resource stocks, and Ecoindicator 99 was used to measure

(toxic) effects on human health and ecosystems, as well as damage to resource quality.

PM10, SO2, and NOx emissions are also measured and compared to complete the environmental impact as part of the overall Life Cycle Assesment (LCA). ICE and Battery-Electric Vehicles (BEV) were modeled as follows:

A new efficient gasoline car (Euro 5 standard) was chosen as a basis for comparison. This ICEV consumes 5.2 L of gasoline per 100 km in the NEDC, resulting in a direct emission of 0.12 kg CO2 per km. The car chosen was representative of neither the European fleet nor the fleet of new cars sold in Europe in 2009: 51.4% of the latter consists of diesel fuel cars with an average fuel consumption of 5.7 L/100 km diesel or 6.6 L/100 km gasoline (calculated from CO2 emissions reported in ref). However, the ICEV was chosen to represent a technological level similar to that of the BEV.

The key finding:

The Li-ion battery plays a minor role regarding the environmental burdens of E-mobility irrespective of the impact assessment method used. Transport services with an ICEV cause higher environmental burdens than with a BEV (ADP, + 37.47% or 261 kg antimony equivalents; GWP, + 55.3% or 37,700 kg CO2 equivalents; CED, +23.5% or 593,000 MJ-equivalents; EI99 H/A, +61.6% or 2530 points). The share of the total environmental impact of E-mobility caused by the battery is between 7 (CED) and 15% (EI99 H/A). Analysis with EI99 H/A showed a relative share of E-mobility caused by the battery that is twice as high as analysis with the other impact assessment methods, and this is mainly at the expense of the operation phase.

Though very different than the NiMH chemistry used in most hybrids, and other cobalt or nickel-based Lithium-ion chemistries, the lithium-manganese-based chemistry modeled for this study uses very little actual lithium (0.007 kg per kg Li-ion battery).

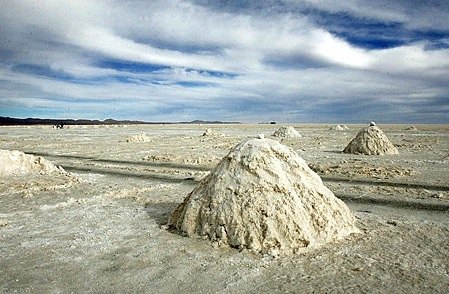

In addition, the processes used to extract lithium from brines are very simple and have a low energy demand. Although lithium occurs in average concentrations lower than 0.01% in the Earth’s crust and hence can be considered to be a geochemically scarce metal, assessment with ADP does not result in a high impact for the lithium components. Li2CO3, the base material for the cathode active material and the lithium salt have an impact of only 1.9%. Compared to other components, for example, Mn2O3 (4.4%), copper (5.3%) or aluminum (15.1%), the abiotic depletion of lithium resources does not seem to be critical. However, these results are valid only as long as Li2CO3 is produced from brines. If the lithium components were based on spodumene, a silicate of lithium and aluminum, the extraction of the lithium would require a considerable amount of process energy… The major contributors to the environmental burden for the production of the battery, regardless of the impact assessment method used, are metal supply and process energy.

Of course, this finding is limited to a certain chemistry of lithium-ion battery, made under certain circumstances, and measured using imperfect (though widely-accepted) standards. Still, it’s something to think about the next time someone argues that EV batteries do more environmental harm than good. The major limitation of EVs, it seems, continues to be the fact that most electricity is generated from highly dirty sources, which hurts the EV’s operational efficiency advantages.

More by Edward Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- SCE to AUX All that lift makes for an easy rollover of your $70k truck.

- SCE to AUX My son cross-shopped the RAV4 and Model Y, then bought the Y. To their surprise, they hated the RAV4.

- SCE to AUX I'm already driving the cheap EV (19 Ioniq EV).$30k MSRP in late 2018, $23k after subsidy at lease (no tax hassle)$549/year insurance$40 in electricity to drive 1000 miles/month66k miles, no range lossAffordable 16" tiresVirtually no maintenance expensesHyundai (for example) has dramatically cut prices on their EVs, so you can get a 361-mile Ioniq 6 in the high 30s right now.But ask me if I'd go to the Subaru brand if one was affordable, and the answer is no.

- David Murilee Martin, These Toyota Vans were absolute garbage. As the labor even basic service cost 400% as much as servicing a VW Vanagon or American minivan. A skilled Toyota tech would take about 2.5 hours just to change the air cleaner. Also they also broke often, as they overheated and warped the engine and boiled the automatic transmission...

- Marcr My wife and I mostly work from home (or use public transit), the kid is grown, and we no longer do road trips of more than 150 miles or so. Our one car mostly gets used for local errands and the occasional airport pickup. The first non-Tesla, non-Mini, non-Fiat, non-Kia/Hyundai, non-GM (I do have my biases) small fun-to-drive hatchback EV with 200+ mile range, instrument display behind the wheel where it belongs and actual knobs for oft-used functions for under $35K will get our money. What we really want is a proper 21st century equivalent of the original Honda Civic. The Volvo EX30 is close and may end up being the compromise choice.

Comments

Join the conversation

What? Who? When? Where? I don't recall anyone moaning about the cost of refilling your Nissan Leaf with Double-As...

Hydropower is ~not~ innocuous; it's certainly good in terms of air quality and CO2, but it's the most dangerous form of power when you consider the body count... Dam failures have killed tens of thousands of people. Hydropower is particularly bad in terms of habitat destruction. One dam can destroy the habitat value of a river for species whose lifecycle involves migration. Fish ladders just don't work... There's a reason they're ripping up hydroelectric dams in the Pacific Northwest. If we want to keep the lights on, we really need to feed our nuclear waste into a sustainable plutonium economy powered by limitless U238 from seawater... But we gotta solve some tough technical problems and clear a lot of ignorance out of the way.