High Yen Drives Japanese Carmakers To Importing More. But Is It Good?

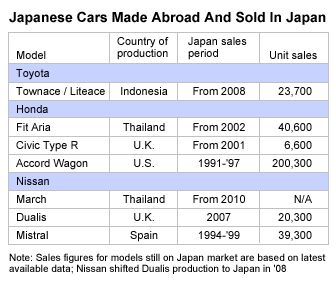

You think Japan is import-adverse? Have a look at that chart that follows, and you will see a wondrous trend: Japanese automakers are importing more and more foreign owned cars to Japan. Some of them even from the U.S. Now, the imports will increase. Not from the US, but from ….

Thailand.

Nissan has started shipping their March subcompact, made at its Thai plant, to Japan The Nikkei [sub] calls it “the first move by a Japanese carmaker to export a mainstay model to the home market.”

The success of the Thai-made car “will have huge implications for the future of Nissan and the Japanese auto industry as a whole,” says the paper. Bringing in cars from abroad is not unusual for a Japanese carmaker, as the table on the left shows. Those were niche models. The Nissan March (known outside Asia as the Nissan Micra) is a whole other story. That’s a volume model. With the Yen going higher and higher, and manufacturing costs in Japan not going down, bringing in a volume model from a low cost country is alluring.

It is also dangerous. Japanese consumers are feared and famous for their high standards. Most stuff on U.S. Walmart shelves would never get sold in Japan. To make sure that their made-in-Thailand cars pass muster, Nissan spent two years training Thai factory workers and tweaking the manufacturing process. Nearly 90 percent of the components for the Thai-made Marches are made in Thailand. That allowed Nissan to sell the car for around $11,000.

Even the cheapest car won’t sell and could turn into a time bomb if the quality is not there. Cars are literally double-checked as they roll off the line in Thailand. When they come off the boat in Japan, they are checked again at Nissan’s Oppama plant. We’ll see how it works out. A stringent quality process usually beats obsessive quality control. You want to avoid throwing stuff away or do costly rework. However, if Nissan pulls it off and can import high quality at low prices into a quality obsessed market, then there may be those huge implications. The Japanese might get very affordable cars. But could be out of a job. Sound familiar?

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jrhurren Worked in Detroit 18 years, live 20 minutes away. Ren Cen is a gem, but a very terrible design inside. I’m surprised GM stuck it out as long as they did there.

- Carson D I thought that this was going to be a comparison of BFGoodrich's different truck tires.

- Tassos Jong-iL North Korea is saving pokemon cards and amibos to buy GM in 10 years, we hope.

- Formula m Same as Ford, withholding billions in development because they want to rearrange the furniture.

- EV-Guy I would care more about the Detroit downtown core. Who else would possibly be able to occupy this space? GM bought this complex - correct? If they can't fill it, how do they find tenants that can? Is the plan to just tear it down and sell to developers?

Comments

Join the conversation

1. Does Honda still sell Fit Aria in Japan? 2. Didn't Honda also, at one time, import vehicles like: Accord coupe, USDM Odyssey and MDX? How about EuroAccord R from the U.K. (circa. ~99-02)? 3. Don't believe cheap goods have no market in Japan. There're many Y100 stores (like dollar stores over here) and, like Wal-Mart, import their goods from China. Of course, they are of (a bit) higher quality.

Re. japanese quality and support expectations ... In 2001, my company got a major business suppling the a major component for the world-wide production of a japanese mid-size car. We would produce the component, alongside an identical component made for our european customers, in our european plant (largest of its type in Europe, highly modern, highly automated, with endless quality awards from every major western OEM), and ship it to Japan, where it would be warehoused and staged for delivery to the customer. I started this business, and so had a 3 month assignment in Japan opening an office, screening employees (we hired 4), selecting logistics providers (we picked 1). I was concerned about legendary japanese quality expectations (and how my company might over-confidently think itself up to the task due to all those euro-Q-awards hanging in the conference room) after I heard so many stories of other supplier's parts having been rejected for defects only noticed in Japan (i.e. suspension parts with paint blemishes, etc.), "defects" that never would have been flagged, much less rejected in, Europe. So we flagged our plant to be on their best behaviour; they were offended by the implication that they were not up to the task. The shipments began, and not long later, the rejections did too. The customer complained. Parts out of spec here, out of spec there, pallet boxes partially filled, pallet boxes empty, pallet boxes filled with parts for our european customer (!), parts with rusty fingerprints, etc. The customer complained again. Additional checks were implemented in Europe ... besides all the automated checks, and end of line checks, and in-plant audits, the parts were then shipped to a remote warehouse, reinspected (so called Firewall-inspection) before going to Japan. In Japan, they were checked once again before being sequenced and delivered to the OEM's plant. The customer complained some more. Fortunately, because of the in-line sequencing in Japan, everything besides the rust and out of spec parts were caught in our warehouse... the plant didn't really believe a) these non-conformanies existed, and b) if they did, it wasn't really all that bad (by european standards), and kept demanding approval to eliminate both the euro firewall check and the japanese sequencing check (to eliminate the chargebacks that were going to the plant.) The customer continued to complain. I kept warning that if we continued to treat this customer this way, the following would happen: a) we would get a bad reputation in Japan, b) the customer would eventually stop complaining and c) we would eventually loose this lucrative business, this customer, and risk losing our japanese beachhead. Our business was growing everywhere but Japan. We won quality awards from our western OEM customers. In Japan, our company was listed on the 'wall of shame' in the purchasing office for too many ppms and too little success in cost-down activities. Management kept pushing the customer to give us other businesses even before we had properly satisfied them by bringing our problems under control ... my european boss, came with me on a trip, and first thing he said after meeting our customer's purchase management for the first time was "I'm here because we want more business." (When he finished blathering, I turned the converstaion back to "he means we want to know where you are not satisfied and unsupported by us, so we can fix these unfortunate circumstances, and, we hope, honour us by considering if we are worthy of more business" (that sort of thing.) The customer complained, the boss made notes of things that had been already known for a couple of years now, we left, the problems still continued. I moved to new responsibilities, we won a major new business in the U.S. We grew elsewhere and continued to earn quality awards from U.S. and european OEM's. Our people in Japan were in daily contact with the customer, we had sales and engineering people regularly (quarterly) visiting from Europe. Somewhere along the way, the customer also felt we were too slow in giving commercial responses and engineering support. Complaints continued, and european team members blamed our japanese team members for the bad quality, and for not keeping their customers under control(!). The new guy who had followed me as sales responsible for this japanese OEM was a good guy, but clearly not understanding what our customer expected. The the problems remained mostly unsolved, and I was offered the job as the "company man" in Japan. Our management really wanted to get more business, but I wanted to fix that which we had first, then turn our efforts to growth. I asked for a 3-man team, me, an engineer, and a quality guy. Rejected. I declined the offer. The complaints continued. Another guy (a good one) took over sales responsibility for the business. A couple of years went by. He did a good job, but without enough understanding and support of management, or cooperation from the plant, he could only do so much. The customer continued to complain. The company continued to search for a westerner (or a japanese w western experience) to serve as the company man. I was offered the job twice more, I repeated my conditions. Twice more rejected. I declined twice more. The customer continued to complain. Via another market, we picked up a sub-component business with another japanese OEM (much smaller business than the running one). A european was sent to fill the company-man job, but located and focused himself on the new business, and aside from occasional visits to our much larger and profitable business at the original OEM, seemed to mostly handle firings of our original staff, and hirings of replacements. The customer continued to complain aobut the product and began to complain about members of the newly hired local staff (along w our european colleagues). Complaints continues, visits continued, engineering discussions were held again and again, non-conformancies were not dealt with, our sales management kept pushing for more business with our original japanese customer. Customer warned that quality was not optimal ... also warned of a shifting in technology away from where we were positioned ... such a change would end our business there ... we stayed on the same steady course toward the shoals... Customer was spending less time complaining... I think few noticed... Customer announced that they would be going with a competitor for this new technology, we heard our customer was having trouble making a sub-component, one for which a european OEM had replaced our competitor by taking our sub-component ... So, our tactics changed, instead of trying to go up from component to system, we started trying to push our sub-component (grab any little bit of business possible)... An engineer was booked to fly and present our proposal ... one day before departure, the engineer was told not to bother coming, they didn't want to see us. The customer had stopped complaining. Summary: What passes for high-tech, high-quality, outside of Japan will not necessarily be so seen in Japan. Going-in, the japanese have high expectations, pay better attention, have more inspection, and generally expect the supplier to deliver what is being paid for. The japanese complain responsibliy, reasonably, consistently, persistently, patiently, but - eventually - they too turn their back on the supplier if the product does not improve. Moral of Story: Get it right before you sell it there, and keep it right!