Toyota: Quality is Job Two

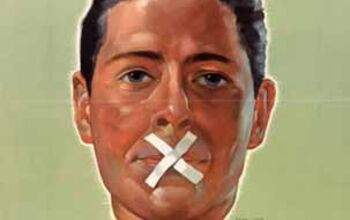

Japanese society is known for its rigid social stratification. Depending on the listener’s relative status, there are four ways to say “this is a book." Individuals within this system are well aware that anyone who moves upwards from their "natural" place in the pecking order risks ridicule, jealousy and attack. Hence the ancient Japanese proverb: “The nail that sticks out gets hammered down." Automotively- speaking, Toyota is the tall nail these days, and boy, is it getting hammered.

Earlier this year, Toyota passed General Motors as the world’s largest automaker. Last month, Toyota’s U.S. operations ended Ford’s 76-year reign as America’s second biggest automaker. If you’re wondering why Toyota hasn’t celebrated these accomplishments with a bit of good old American swagger, see paragraph one. The Japanese carmaker knows it’s in the crosshairs. For now, the company figures that silence is the better part of valor.

The problem is simple: Toyota’s reputation exceeds them. The automaker is famous for building vehicles that never break, rust, fail or fall apart. Automobiles that are so well-built they’ve stood the old ‘70’s idea that “made in Japan” means cheap on its head. Toyota’s reliability rep is so strong that a disgruntled aircraft owner recently evoked the company’s mythical mechanical prowess on an internet forum: “I want Toyota to make a single engine piston [airplane].”

For some time, domestic supporters have been trying to tell American consumers to stop drinking the Toyota Kool Aid. Citing independent surveys, they claim The Big 2.8 have narrowed the quality gap to the point where it’s statistically meaningless, making the discrepancy a matter of [misinformed] perception. More to the point, they say the Japanese company is no stranger to product delays and recalls, and mechanical issues. Which is true.

While Toyota’s design, parts and production process remains second to none, carmaking is such a vastly complex business, and Toyota such a vast enterprise, that mistakes are inevitable. No carmaker– or car– is perfect. Toyota’s recent problems with the new Tundra pickup’s defective camshafts illustrate the simple fact that shit happens– especially when you’re building a new product in a new factory using new suppliers.

Still, there’s no question that Toyota’s rapid expansion in the North American market is giving the company growing pains– or should I say, continuing to challenge the storied Toyota Production System. Ironically enough, Toyota is suffering from a perception gap. Their quality problems are not significantly worse than before, but the company’s newly assumed tall poppy status makes them seem so. Simply put, people are paying attention.

Well, the media is, as witnessed by the relatively prominent play given the Tundra screw-up. That said, it would take at least a decade of crap Toyota products and bullet-proof Detroit metal to reverse the curse. And no matter what The Big 2.8 do or don’t do, Toyota is not about to let its products suffer from endless rounds of mechanical mishaps and expensive recalls.

Toyota is taking radical action to sort out its North American quality woes. The company is currently retraining ALL of its North American assembly workers. This “back to basics” course is designed to identify and correct defective working practices and highlight the need for increased front line vigilance. At the same time, Toyota is devolving decision-making powers and back office support from its Erlanger, Kentucky headquarters to regional centers in California and Texas.

Anyone who thinks Toyota will ease-up on its commitment to product quality, brand integrity and customer satisfaction is delusional. The automaker is nowhere near the peak of its global or national ambitions, and they know exactly what they have to do to get there. And make no mistake: Toyota’s current production problems are NOT a reflection of corporate hubris. They're a direct result of their desire to keep a low profile. To avoid the hammer.

How’s this for an inconvenient truth: building vehicles abroad would be the easiest way for Toyota to assure product quality and increase profits. They refrain from doing so for political reasons. The Japanese automaker knows that their top dog status makes them the logical scapegoat for failing American automakers. Planting factories on U.S. soil at least partially protects them from the slings and arrows of outraged patriots.

Speaking to Automotive news, management guru Jim Womack went further. The co-author of a seminal book on Toyota’s lean, mean production machine claims that the American political landscape makes it difficult for Toyota to be Toyota.

"The short-term rate of expansion in the States is not being driven by long-term judgment about what is truly best for the business as a business," Womack said. "Rather, it's being driven by an assessment of what is necessary for the company due to short-term politics.

“Toyota is terrified that it will be blamed for the collapse of Ford and the potential collapse of Chrysler, followed by GM."

If you were wondering how such a successful automaker could have such a paranoid corporate culture, it's best to think of Toyota's psychology as the reverse of Abraham "hierarchy of needs" Maslow's aphorism. When you're a nail, everything looks like a hammer.

More by Robert Farago

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Zerofoo 5-valve 1.8T - and OK engine if you aren't in a hurry. These turbocharged engines had lots of lag - and the automatic transmission didn't help.Count on putting a timing belt on this immediately. The timing belt service interval, officially, was 100,000 miles and many didn't make it to that.

- Daniel J 19 inch wheels on an Elantra? Jeebus. I have 19s on my Mazda 6 and honestly wish they were 18s. I mean, I just picked up 4 tires at over 1000 bucks. The point of an Elantra is for it to be cheap. Put some 17s on it.

- ToolGuy 9 miles a day for 20 years. You didn't drive it, why should I? 😉

- Brian Uchida Laguna Seca, corkscrew, (drying track off in rental car prior to Superbike test session), at speed - turn 9 big Willow Springs racing a motorcycle,- at greater speed (but riding shotgun) - The Carrousel at Sears Point in a 1981 PA9 Osella 2 litre FIA racer with Eddie Lawson at the wheel! (apologies for not being brief!)

- Mister It wasn't helped any by the horrible fuel economy for what it was... something like 22mpg city, iirc.

![Toyota: [Falling] Quality is Job One](https://cdn-fastly.thetruthaboutcars.com/media/2022/06/28/8378066/toyota-falling-quality-is-job-one.jpg?size=350x220)

Comments

Join the conversation

Quick comment on the built/engineered in Japan vs USA observation: I am a major Honda/Acura fan (having a few friends that work with them in Marysville and Anna, OH helps) and maybe it is my perception, but yes, I do feel there is a difference. My last new car, an Acura RSX Type-S was one of the few Honda products still designed and built in the Land of the Rising Sun (I verified - mind is drawing a blank, but I want to say it was built in Hiroshima - I remember I had to wait for it to cross the ocean and arrive in Seattle before crossing the country to the east coast.) While the interior door panels bordered on spotty given the hard plastic, the rest of the interior and exterior looked and felt solid and reliable. At one time, I was recently looking at the S2000, and it is the same story - although I'll agree with any critics that the "metal" panel that covers the stereo is terrible. The new Civic, however, seems to have taken a slight step backwards in terms of interior quality. I don't think the drop is as steep as a Camry (having friends and family with several generations makes a great measuring stick.) On the other hand, explain the Korean manufs? When they came here, they improved with each generation and they were no pushover in their home market. Toyota is still well above average in correcting their problems which borders on stunning given the size of the company. In my "home base" area around Cincinnati, their growth (shout out to Erlanger) has been rapid and 70 miles down the road, the massive complex in Georgetown hires tens of thousands of Kentucky workers to stable and secure jobs that assemble reliable cars. Personally, I'll take that any day of the week instead of the constant worry that GM, Ford, and whatever Chrysler will call themselves - that they will continue to shed jobs, ruin lives with closings, and destroy their suppliers from around the world. One other thing - speaking of improving an initially "damaged" product, how about Nissan/Infiniti? When the new leadership team took over, Nissan was coming out with some striking designs, but the interior quality was just terrible. With the recent refresh of the Maxima and 350Z, far more soft-touch plastics and better quailty seat materials were installed. With the redo of the Altima and G35, they nailed it right in terms of a quality feel. Toyota can do the same. Maybe, like Nissan, they need to reel in costs for the time being. Once the purse strings are loosened a bit, they can improve the Camry and Avalon interior. Of course, that doesn't excuse the junk that replaced the xB.

Toyota's interiors have never been all that great in my opinion, save for Lexus. Take a look at the Celica and MR2 Spyder before they met their demise; those are positively trashy. The current tC isn't that much better. If you want something nice, you pretty much have to go with Honda or something European.