Tesla Owner Finds Torn A-Pillar on Freshly Delivered Model S

Imagine you’ve just taken delivery of a car with a price tag of $127,100. You’re leasing it for a monthly sum that could pay for a nice two-bedroom apartment in most North American cities.

The A-pillar is torn. Split. Structurally compromised. And it was delivered that way from the factory.

According to one Toronto-area man, that’s the situation he’s facing with a brand-new Tesla Model S 90D.

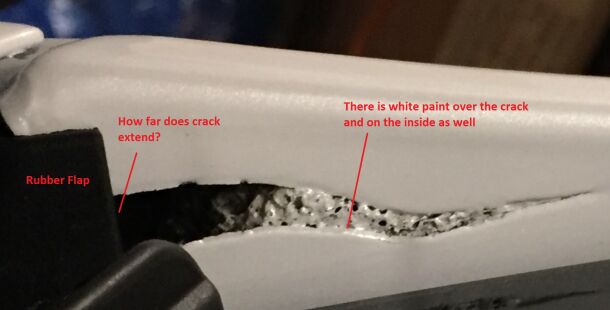

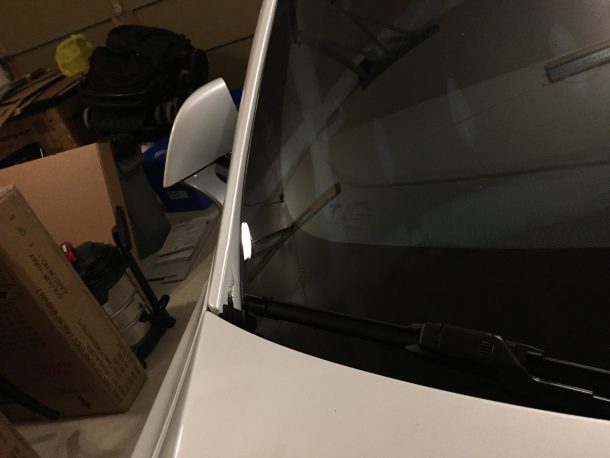

On Tuesday, a Canadian Tesla Motors Club member — aptly named Snowstorm — posted a fairly shocking indictment of the automaker’s quality control to the club’s forum. Photos posted by the member appear to show a gaping tear in the passenger-side A-pillar just above the hoodline. The crack, wider at the bottom than the top, descends out of sight below the lower windshield trim.

Given that there’s white paint spanning the gap in places, one can only conclude that the damage occurred at the factory.

Snowstorm describes the discovery:

I picked up my S90D last Friday and was super happy about it, there was some trim mis-alignment on delivery but nothing serious. Today, I was showing off the car to my brother in-law and noticed something very wrong with the A-Pillar. On the passenger side where it touches the front of the windshield, the aluminium was actually cracked and there is a gaping hole to the inside! There is no way that I would have actually caused this and you can see that they painted the crack part as well.

After emailing the delivery contact, Snowstorm continued in a follow-up post:

How can the delivery folks not see this as they are prepping the car? Would have been obvious on a wash. I don’t even know how can the part be replaced without taking apart a lot of things. If I saw this on delivery, I would have asked for a different car…

Ignoring the part where misaligned trim on a six-figure car is perfectly acceptable, Snowstorm’s tale is alarming. The Model S’ high-strength aluminum side member is a one-piece unit stretching from A-pillar to C-pillar. Given the piece is a structural component, this owner runs the risk of having his car deemed unroadworthy.

This discovery comes after Tesla posted a record number of deliveries in the first quarter. The increased output and recent investment news sent the automaker’s stock soaring this week, with the company’s market capitalization surpassing Ford and eventually General Motors.

On the forum, most of the members expressed shock at the damage, and some anger — not something you see everyday on a fan site. While Snowstorm began the process of rectifying the crack right away, repairs come with annoyances, even for a regular automaker with an established dealer network.

From yesterday morning:

I emailed the pics to the service center and my delivery speaclist [sic] last night. Got a call from them this morning to bring it in at 11am. The service center place said this need to go to their “certified body shop” for an evaluation. Unforunately [sic], there is only 2 body shop in the greater Toronto area and they are pretty busy. Once it gets there, they’ll decided what part to order and rebuild. Not sure how long it will take, but I am concerned due to all the horror stories I’ve heard on months and months to wait. It really sucks to have to do major body work on a brand new car and then be without it for months just 4 days after delivery.

Snowstorm claimed the delivery person “was a bit defensive” after hearing about the issue, with the contact apparently refusing to believe the car could be delivered in such a state. The paint stretching over the crack was apparently all the evidence the owner needed to prove it wasn’t his fault.

Later in the day:

I got in contact with my delivery manager Jenny in Toronto and mentioned about the rebuild. She is sympathetic to the situation but needs to speak with the service manager and the body shop tomorrow AM before deciding what to do. I looked at the loaner and noticed that the broken part appears to be part of the entire side frame and not just a trim piece

While Snowstorm claims to not posses a Twitter account, at least one user brought the crack to the attention of Tesla CEO Elon Musk on his behalf. The Model S arrived at the body shop last night.

Early this morning, an update:

Tesla is being proactive in following up with me and the regional service manager is aware of what’s happening. I am in contact with Kevin, the Mississauga ON service manager now. He thinks this is highly unusual and is awaiting an assessment from the body shop to look at the extend [sic] of the defect and proposed fix.

So far, it seems like Tesla has stayed in close touch with the owner, who mentions the outreach several times. While Snowstorm hasn’t been painted as the culprit behind the crack, this Canuck’s saga seems far from over, and we still don’t have answers on what caused the cracked metal. Indeed, we’re not sure if the owner will ever receive an answer.

Quality control issues are no stranger to the Model S and especially the Model X, what with its Exorcist-like doors, but past claims by Musk have sought to allay fears on similar issues cropping up on the upcoming Model 3. That affordable electric sedan goes into production late this year, with the company’s long-term hopes pinned squarely to its featureless face.

A torn A-pillar in a newly built car isn’t going to cause investors, Tesla executives or Model 3 reservation holders to breathe any easier.

[Images: Tesla Motors Club Forum]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy "Note that those vehicles are in direct competition with models Rivian sells"• I predict that we are about to hear why this statement may not be exactly true

- ToolGuy From the relevant Haynes Repair Manual:"Caution: The 4.6L models require a special tool to extract the water pump from the coolant crossover housing. This special tool is expensive and the removal procedure is difficult. Have the water pump replaced by a dealer service department or other qualified automotive repair facility if the tool is not available."One version of the tool is Lisle 14440; I paid $10.82 (less 5% discount, plus shipping).You can see why I never attempt my own maintenance or repairs. 😉

- Dave M. IMO this was the last of the solidly built MBs. Yes, they had the environmentally friendly disintegrating wiring harness, but besides that the mechanicals are pretty solid. I just bought my "forever" car (last new daily driver that'll ease me into retirement), but a 2015-16 E Class sedan is on my bucket list for future purchase. Beautiful design....

- Rochester After years of self-driving being in the news, I still don't understand the psychology behind it. Not only don't I want this, but I find the idea absurd.

- Douglas This timeframe of Mercedes has the self-disintegrating engine wiring harness. Not just the W124, but all of them from the early 90's. Only way to properly fix it is to replace it, which I understand to be difficult to find a new one/do it/pay for. Maybe others have actual experience with doing so and can give better hope. On top of that, it's a NH car with "a little bit of rust", which means to about anyone else in the USA it is probably the rustiest W124 they have ever seen. This is probably a $3000 car on a good day.

Comments

Join the conversation

Here you go...NHTSA have now published my complaint. Is this "fraudulent" or what? Sorry bout the capital letters..that's just NHTSA shouting to get Ewon's attention. April 5, 2017 NHTSA ID NUMBER: 10970820 Components: STRUCTURE NHTSA ID Number: 10970820 Incident Date April 3, 2017 Consumer Location BEVERLY HILLS, CA Vehicle Identification Number UNKNOWN**** Summary of Complaint CRASH Not yet FIRE Not yet HERE IS A REPORT FROM AN OWNER OF A BRAND NEW MODEL X THAT HAS A CRACKED IN HALF A-PILLAR. HTTPS://TESLAMOTORSCLUB.COM/TMC/THREADS/HELP-A-PILLAR-DEFECT-FOUND.88657/ PHOTOGRAPHS ARE ATTACHED. SNIP "I PICKED UP MY S90D LAST FRIDAY AND WAS SUPER HAPPY ABOUT IT, THERE WAS SOME TRIM MIS-ALIGNMENT ON DELIVERY BUT NOTHING SERIOUS. TODAY, I WAS SHOWING OFF THE CAR TO MY BROTHER IN-LAW AND NOTICED SOMETHING VERY WRONG WITH THE A-PILLAR. ON THE PASSENGER SIDE WHERE IT TOUCHES THE FRONT OF THE WINDSHIELD, THE ALUMINIUM WAS ACTUALLY CRACKED AND THERE IS A GAPING HOLE TO THE INSIDE! THERE IS NO WAY THAT I WOULD HAVE ACTUALLY CAUSED THIS AND YOU CAN SEE THAT THEY PAINTED THE CRACK PART AS WELL. I HAVE EMAILED MY DELIVERY PERSON AND AM SUPER SAD ABOUT THIS AS I DON'T KNOW HOW THEY CAN ACTUALLY REPLACE THAT PART WITHOUT RIPPING APART THE CAR. THIS CRACKED PART IS OBVIOUSLY UNACCEPTABLE BUT I DON'T WANT THEM TO CAUSE MORE ISSUES RIPPING IT APART TO REPLACE IT. WHAT SHOULD I DO?" IT IS SCANDALOUS THAT SUCH A SERIOUS STRUCTURAL DEFECT COULD PASS QUALITY CONTROL. THIS IS YET ANOTHER EXAMPLE OF TESLAS BEING RUSHED OFF THE PRODUCTION LINE IN ORDER TO MEET QUOTAS WHILE IGNORING THE PRODUCTION DEFECTS. PLEASE INVESTIGATE HOW THIS CAR WAS ABLE TO ESCAPE FROM THE FACTORY. CONCERNED CITIZEN ETC.

Dustin, the regional service manager in my area, reached out to me yesterday and confirmed that Tesla will be building a new Model S for me. The logistics of the actual transfer still has to be worked out (lease, government rebate in progress etc...) and I'll need to build a new Model S where the option and prices have changed a bit in my region (e.g. one up) since I built mine last November. Overall, it is disheartening to see such a defect on a brand new car and it is a hassle to deal with. Nevertheless, the Tesla service team have been going a good job so far in helping me remedy the situation. I do hope the replacement process will be smooth and they'll fix whatever issue that cause this in the 1st place. I didn't hear anything about what caused the original problem or what will become of the original Model S, I'll let you guys know when/if find out.