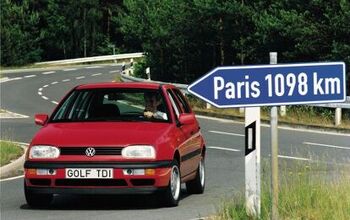

Volkswagen Waited Six Years to Use 'Defeat Device': Report

The device Volkswagen used to cheat on emissions tests sat on a shelf for years before the automaker employed it on its diesel-powered vehicles.

Audi engineers created the software in 1999, but it was not immediately used by Volkswagen, according to the German newspaper Handelsblatt (via Reuters).

That changed in 2005, when VW engineers found themselves unable to bring the emissions of their new TDI engines into compliance with existing laws. The German report cites industry and company sources.

To deal with the inconvenient emissions, Audi’s software — which was capable of turning off certain engine functions — was taken off the shelf and employed in the new models. Eventually, a total of 11 million vehicles across the company’s model range were equipped with the device.

Volkswagen and Audi were silent in the wake of the report, citing the ongoing U.S. investigation into the diesel emissions scandal. Law firm Day Jones is expected to publish a detailed report of their findings at the end of the month.

The scathing revelation comes on the eve of a crucial deadline imposed by a U.S. District Court judge, regarding the company’s plan to fix its diesel models. Volkswagen has until April 21 to outline a comprehensive plan to bring the affected vehicles into compliance with U.S. environmental regulators.

More by Steph Willems

Comments

Join the conversation

It vas not us! It was ze, how you say, "bad Germans" over at ze Auto Union! Ve are ze "good Germans" like ze cuddly Sergeant Schultz from your Hogan's Heroes program.

The "Easy" button strikes again.

Sense of things to come? http://www.autonews.com/article/20160420/OEM11/160429985/vw-to-hike-diesel-scandal-provisions-to-double-digit-billions-of

It doesn't matter why that software was written initially. Software is always developed with a lot of "instrumentation" code to permit testing or debugging, but as it moves to production-quality, very little of that (if any) is included. There will still be ways to "debug" production code -- those are generally standardized, but do not involve altering the behavior of the entire system. They are strictly meant to help create a reproducible test case which can be brought back to a development environment where more and pricier tools and equipment are available to fully trouble-shoot the offending code or component. Two more facts: a. ECM software is thoroughly tested, and doesn't generally contain any bugs of serious consequence; b. typical engineering reviews of any large/complex or safety-related software such as ECU programming take months and involve many from various parts of the organization scrutinizing every single line of code. This is the most fun-less (painful?) experience for any techie seeing their code off to market. If there was a breakdown in the internal processes at VW, there would be tons of other much more serious (dangerous?) flaws in ECU code, and they'd have been discovered in the wild. If they dropped all internal controls just for this cheat to move to production, it was a deliberate act (and at that point it doesn't matter if it was developed for testing only, or explicitly for use in production).