Editorial: Get Ready For Massive Recalls Driven By Modular Platforms

Today’s recall announcement by Toyota estimated to span at least 6.4 million vehicles, serves as a nice distraction from the ongoing recall occurring at cross-town rival General Motors. The Best & Brightest are free to squabble about which faceless corporate entity with zero regard for their individual well-being is the superior one. The rest of us have bigger fish to fry.

At 6.4 million vehicles, this Toyota recall is massive. It won’t be the last one. In fact, I think that ten years from now, this will be a low number.

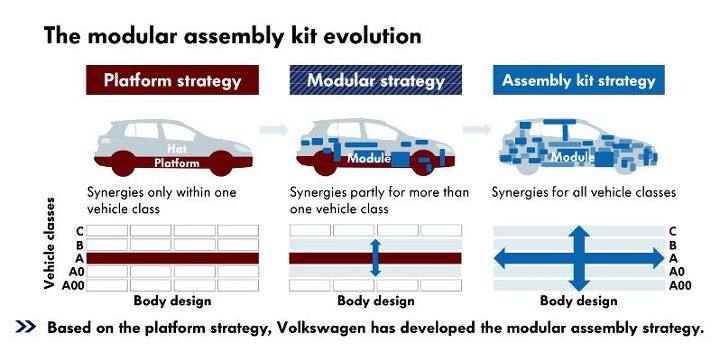

The big trend in the auto industry today is modular platforms, which allow an enormous range of vehicles to share components. Volkswagen’s MQB architecture is an oft-cited example of this, largely because it takes a holistic approach to modularity. Much like Lego bricks, different “modules” can be assembled to create different vehicles. MQB is capable of spawning everything from a B-segment Volkswagen Polo to a D-segment Volkswagen Passat to an Audi TT sports car to a Volkswagen Touran minivan. Only a small number of “hard points” like the dimension from the center line of the front wheel to the pedal box, or the engine mounts, are fixed.

Within these modules are a high level of common parts, designed to be used across the entire range of MQB vehicles. This can include everything from whole powertrains to braking systems to smaller components that could be shared across a range of small to mid-size vehicles – which is, in theory, a truly vast quantity. Other commentators have expressed worries that MQB will lead to components being mismatched to their application. An A/C system engineered for a Passat might be overkill on a Polo (or vice versa) from a utility or financial standpoint.

From a purchasing standpoint, MQB will allow Volkswagen to buy lots and lots of widgets, receiving a significant discount on the cost per widget. This will equal significant savings for VW (though just how much they’ll save seems to depend on who you ask) while leading to shorter assembly times and more standardized production of vehicles. In the event that demand for a given model changes, a factory could scale back production of a slower selling model to help meet demand for the more popular one. This gives Volkswagen unprecedented flexibility in the way that cars can be designed, engineered and manufactured.

It also leaves Volkswagen in a very vulnerable position. What happens if they get a bad batch of widgets from a supplier, or the widget in question was poorly engineered? What if a manufacturing process was poorly designed, and the widgets aren’t installed properly? With so many vehicles assembled with the same faulty part or process, the impact could be enormous: millions of vehicles requiring repair, a black eye for Volkswagen and, heaven forbid, human lives negatively impacted.

This kind of exposure to potential quality defects and mass recalls was dubbed a “Cascading Failure” in a prior article, but many readers with engineering backgrounds objected. Instead, we can call it a “platform level failure”, which is the key difference between the scenario outlined above, and the Toyota recall, which affects everything from the Yaris subcompact to the Land Cruiser SUV.

But in a future where every car maker will have to adopt some kind of modular architecture, the likelihood of these events occurring is almost certain. And those who have invested most in common vehicle architectures are at the greatest risk.

More by Derek Kreindler

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Analoggrotto GM under Bob Lutz.

- Aja8888 For that kind of money, you can buy a new 2024 Equinox!

- Ras815 The low-ish combined EPA rating on the hybrid version might be a bit misleading - I'd imagine in a real-world case, you could see a substantial improvement in around-town driving/hauling compared to the gas equivalent.

- Lim65787364 Melissa needs to be get my money back up and for new car payment

- 3-On-The-Tree Lou_BCAnd at the top for critical shortage’s to include law enforcement.

Comments

Join the conversation

You're leaving out one part of the equation. Sharing same parts among more models means that if the part goes wrong, the recall is larger. But, at the same time, it means that there is less variants of said parts to go wrong. Which means that there will be bigger recalls, but less of them. And it could be argued that since there will be less parts to design, automakers will be able to put more effort into designing each of them, so recalls can, in the end, be more scarce than they are now.

Does it follow that there would be fewer recalls if platforms were not modular? Or is the issue not modular but quality control?