Guest Post: Society Of Automotive Analysts Reliability Study

From time to time someone comes to me with a great idea: instead of surveying car owners to get TrueDelta’s reliability stats, why not use warranty claims data? The reason why not: manufacturers consider such data to be highly proprietary. So when I heard that the auto industry’s “first OEM warranty and recall study” was going to be presented at a Society of Automotive Analysts meeting, I was intrigued. Had someone gotten their hands on this data? What were they able to learn from it?

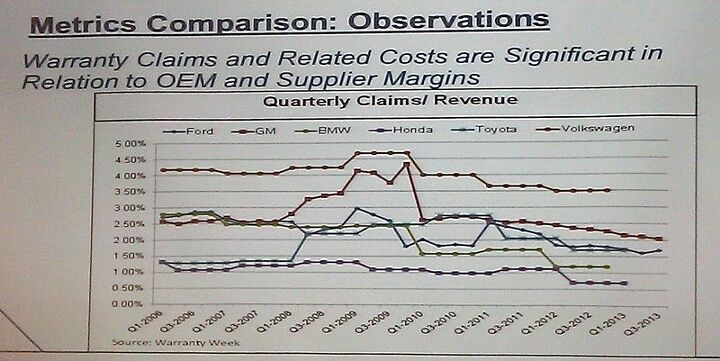

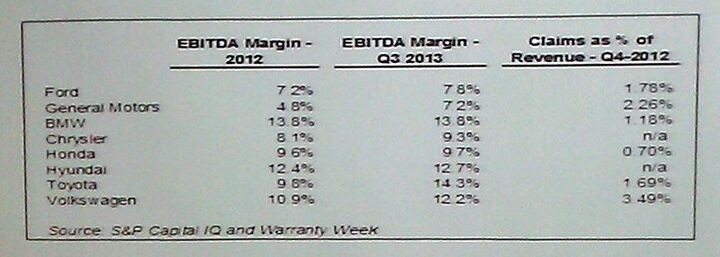

It turns out that Stout Risius Ross, the financial consulting firm that conducted the study, didn’t have access to any proprietary data. Instead, they used recall filings and the manufacturer-level data available in financial statements. Recall filings include the number of cars affected. Annual costs of warranty claims must be disclosed in financial reports. These data tend to be messy, as different companies include different things in these costs; there’s no precise universal standard. Also, multiple model years are often lumped together, and changes in both warranty claims and recalls lag changes in the number of cars sold. Keep these limitations in mind when viewing the “warranty claims as a percentage of revenue” comparison.

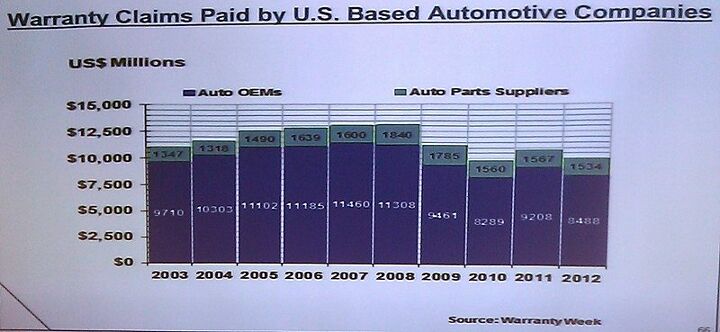

The presenters downplayed the relationship between recalls and quality, as the latter includes things gone right as well as things gone wrong. So what’s the point of studying all of this warranty and recall data? The usual point for a business audience: money. Warranty claims and recalls cost manufacturers billions of dollars each year. Finance needs to be able to predict these costs so they can set aside appropriately sized contingency funds.

Of even greater interest to the people in the room: who pays. OEMs want suppliers to pick up half or more of the cost of warranty claims and recalls. So far suppliers have been picking up only a small fraction of these costs, but OEMs have been getting more aggressive. Suppliers are smaller, sometimes much smaller companies. A big recall could bankrupt them—if they had to pay for it, and they were not insured.

To help them not pay for it, they can hire good lawyers. One was on the panel. To the many suppliers in the room he suggested “if you’re not at the table, you’re part of the meal.” To avoid getting stuck with the costs of recalls and warranty claims, suppliers must first push to be included in any discussions the OEMs have regarding who pays. Otherwise they’ll just receive an invoice.

Despite the availability of excellent legal assistance, a supplier might end up having to pay out millions for a recall or warranty claims anyway. To protect themselves, they can buy insurance. The price of this insurance will depend on calculations of risk. Currently, no one outside the OEMs has good data on the costs of recalls and warranty claims. To fill this need, we have this study.

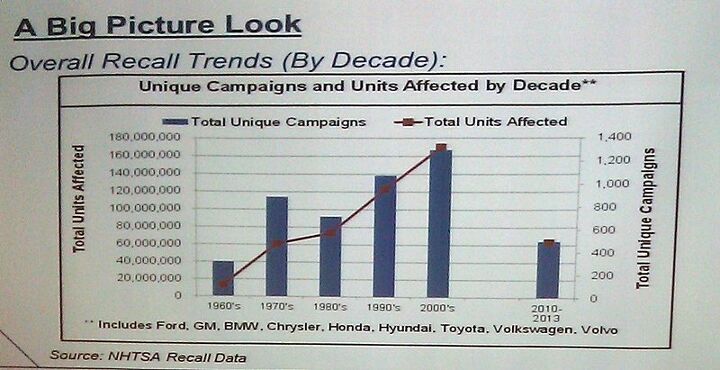

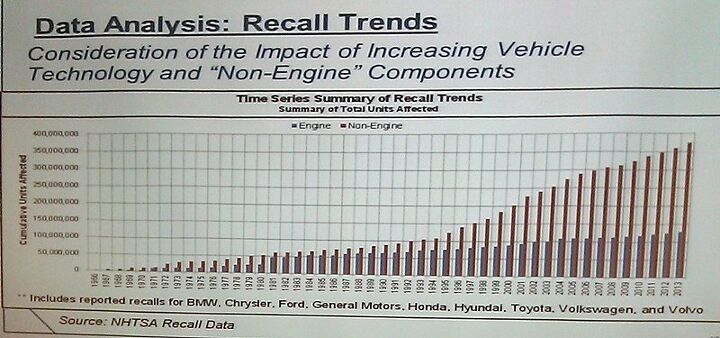

Two trends of greater interest to car owners did come up in the presentation. The first is fairly well known: warranty costs have been declining as cars’ reliability (a narrower term than quality) improves. The second trend is much less well-known: since the mid-1990s the number of cars recalled each year has been surging. The presenters weren’t able to get too far into the reasons for this. The addition of airbags has been one driver. When cars didn’t have them, they couldn’t be recalled. In recent years airbags have been one of the most frequently recalled systems. Engine-related recalls have grown much less quickly than non-engine-related ones. Also, the NHTSA has gotten more aggressive. The lawyer on the panel offered protection from big government—it’s important to push back.

A third driver of the increasing number of cars recalled wasn’t part of the presentation. To increase economies of scale, OEMs have been striving to communize as many parts as possible across multiple products. As a result, when a critical part does fail, a much larger number of cars can be affected. The number of cars recalled has grown faster than the number of recalls.

This is just the initial phase of a planned annual study. Perhaps they’ll be able to get more detailed data in the future? Unfortunately, this doesn’t seem likely. The people in the room (OEMs, suppliers, business consultants) generally agreed that the companies should not have to disclose any more detail; model-level information should be proprietary, and the requirements suck up an excessive number of person-hours already.

Michael Karesh lives in West Bloomfield, Michigan, with his wife and three children. In 2003 he received a Ph.D. from the University of Chicago. While in Chicago he worked at the National Opinion Research Center, a leader in the field of survey research. For his doctoral thesis, he spent a year-and-a-half inside an automaker studying how and how well it understood consumers when developing new products. While pursuing the degree he taught consumer behavior and product development at Oakland University. Since 1999, he has contributed auto reviews to Epinions, where he is currently one of two people in charge of the autos section. Since earning the degree he has continued to care for his children (school, gymnastics, tae-kwan-do...) and write reviews for Epinions and, more recently, The Truth About Cars while developing TrueDelta, a vehicle reliability and price comparison site.

More by Michael Karesh

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- 28-Cars-Later I know someone who would snap this up for the right money, but Ontario and likely the ask would prohibit it.

- Buickman dumb questions generate responses.

- Buickman wouldn't have one if it was free, seriously speaking.

- Arthur Dailey So please tell me, how long are you willing to wait to get one?Reported delivery times of over 18 months for the RAV-4 hybrid.Then in the Toronto area, if you do get one, what are the chances that it will not be stolen? The CRV and the RAV-4 are among the most popular vehicles for car thieves up here.

- TMA1 2018 GTI, purchased early 2019. One warranty repair so far. Check engine light came on a few days ago. Good thing it came with a 6-year factory warranty. Thanks, Dieselgate!

Comments

Join the conversation

Interesting article. Good to see Michael back. My takeaway: VW's claims as a % of revenue are 5X Honda's. Five times. Wow.

Perhaps there is another way...Technical Service Bulletin TSBs...is there a way to collect and list all reported and published TSBs released or sent out by manufacturers? So...although these are not life threatening, they do show a repair or issue important enough that a TSB had to be sent out. Are these available to use as data?