Tesla Unveils $5 Billion Gigafactory

After months of speculation, Tesla drew back the curtain on their most ambitious project to date, the Gigafactory.

Yahoo News reports the Gigafactory’s price tag would total $5 billion, $2 billion of which would directly from Tesla — including a portion from a proposed $1.6 billion convertible note offering that will also be used for future vehicle development — with current partner Panasonic and their partners fronting the remainder of the investment. Interestingly, Morgan Stanley announced it was expecting to c ollect underwriting fees from the note just one day after also issuing a research memo that called for a doubling of their price target for Tesla shares.

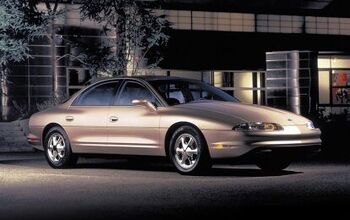

Four sites in Arizona, Nevada, New Mexico and Texas are under final consideration for the site of the Gigafactory, and the finished project will employ 6,500 workers. The first goal for the Gigafactory is to begin construction this year in time to open its doors in 2017 at the same time the low-cost Model E is set to enter showrooms, with battery costs projected to fall 30 percent in the same timeframe. The milestone will be followed by a push to increase cell and pack outputs by 35 and 50 GWh/yr by 2020, where Tesla expects to move 500,000 units a year into showrooms around the world. Despite widespread reports to the contrary, Musk told Bloomberg that Panasonic’s participation “ is not 100 percent confirmed“.

Seattle-based writer, blogger, and photographer for many a publication. Born in Louisville. Raised in Kansas. Where I lay my head is home.

More by Cameron Aubernon

Comments

Join the conversation

This is great. make a computer drawing and the stock goes up 20%. I am starting to think SCTY has more potential than TSLA. I do admire the style he gives the car. That should be the easiest thing for a mfg. to do, but for some reason, nobody does it. Thanks Mr. Musk for paying back your loans, and good luck to you.

Here's hoping my native home state, the Great State of Nevada, gets the nod. Screw those other states, especially that absolute crazy land of Arizona, with their openly discriminatory stances on stuff. Texas has plenty of manufacturing. Spread the love, Elon. Plus we are closer to the plant.

Don't go to Texas, where the state is considering ways of limiting Tesla's direct sales.

There is just no way Tesla goes to TX unless he is using the Gigfactory as a bargaining chip to get the state to reverse its position on direct sales. NV IS the most likely location for this pie in the sky project. In fact, there may be no Gigfactory. Panasonic hasn't yet agreed to join. Why would they? The money hasn't been raised. And any factory that employees 6500 workers is extremely vulnerable to a Chinese competitor. Recall what happened to Solyndra.