ZF and Levant Power Develop Regenerative Active Suspension

ZF Friedrichshafen AG and Levant Power Corp., a Woburn, Massachusetts technology company spun off from MIT, have announced what they call the first fully active suspension system that includes a regenerative function that recovers energy from the motion of the suspension. The system is branded GenShock. Active suspensions are not new, General Motors experimented with an actively suspended ZR-1 Corvette when the automaker owned Lotus, which had worked with active suspensions before the technology was banned in Formula One. Going back even farther, there were the hydropneumatic Citroens and the last true Packards’ “torsion level” suspension. With road cars the goal in using such a system would be to combine good ride with good handling, soft sometimes and stiff sometimes, depending on the driving circumstances. Early tries at developing what chassis engineers call a “high bandwidth active suspension”, capable of dealing with those varying circumstances, have run into cost, complexity and power consumption issues. The GenShock system is claimed to be affordable, simple to integrate in existing suspension designs, and not only have modest power consumption but also be able to recover energy from the suspension.

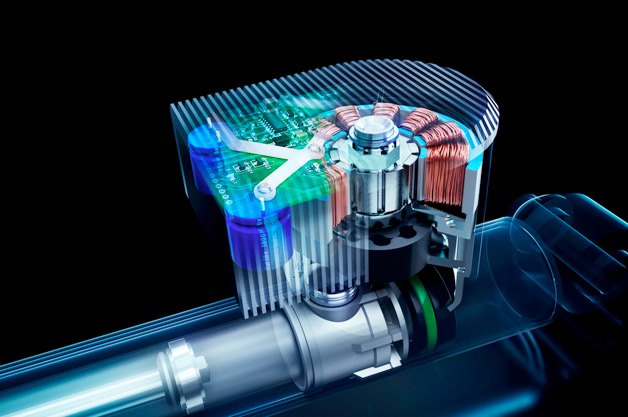

The heart of the system is what Levant Power calls the Activalve TM, a device that combines electric and hydraulic motors (the companies are calling that an “electrohydraulic gear pump”) and can be adapting to standard mono, twin, and tri-tube damper configurations. Hydraulic fluid in the shock absorber is routed from the damper body through the valve, where the electric motor can be used to control the flow of fluid through the gear pump, or alternatively, the pump can be used to drive the electric motor as a generator, recovering electricity. The poorer the road quality, the more bumps there are, the more energy is recovered. Electronic controls adapt the damping characteristics to the driving situation, reducing body pitch and roll during cornering and braking. While the system adds a little bit of weight, compared to a passive suspension, it also eliminates the need to carry a jack, since the system is capable of raising or lowering each wheel independently.

Note that this is not a perpetual motion machine, like putting a wind generator on a car. It creates no new load on the powertrain, it merely recovers energy that would normally be turned into heat. ZF and Levant Power haven’t released any figures on just how much energy is recovered and whether that exceeds the power required to run the system. Like Innowatech‘s piezoelectric roadways, BMW’s Turbosteamer concept, or Purdue professor Xianfan Xu’s work recovering electricity from engine exhaust using large scale Peltier devices, the GenShock is harvesting energy that would otherwise go to waste.

More by TTAC Staff

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- BrandX "I can charge using the 240V outlets, sure, but it’s slow."No it's not. That's what all home chargers use - 240V.

- Jalop1991 does the odometer represent itself in an analog fashion? Will the numbers roll slowly and stop wherever, or do they just blink to the next number like any old boring modern car?

- MaintenanceCosts E34 535i may be, for my money, the most desirable BMW ever built. (It's either it or the E34 M5.) Skeptical of these mods but they might be worth undoing.

- Arthur Dailey What a load of cow patties from fat cat politicians, swilling at the trough of their rich backers. Business is all for `free markets` when it benefits them. But are very quick to hold their hands out for government tax credits, tax breaks or government contracts. And business executives are unwilling to limit their power over their workers. Business executives are trained to `divide and conquer` by pitting workers against each other for raises or promotions. As for the fat cat politicians what about legislating a living wage, so workers don't have to worry about holding down multiple jobs or begging for raises? And what about actually criminally charging those who hire people who are not legally illegible to work? Remember that it is business interests who regularly lobby for greater immigration. If you are a good and fair employer, your workers will never feel the need to speak to a union. And if you are not a good employer, then hopefully 'you get the union that you deserve'.

- 28-Cars-Later Finally, something possibly maybe worth buying.

Comments

Join the conversation

I read all the negativity, and I remember my friends who would not buy a car with an automatic transmission because "it would break". Also, a friend that would not buy a car with electronic ignition because "it would break". You can be sure that if this active suspension system is put into mass production, it will be OK. If not the first iteration, by the time it works down to mass market vehicles, it will be OK. The same with electric cars. The first generation cars are not practical. The early adopters pay the price for buying early. People who wait, get the perfected product. But, without the early adopters, there would be no perfected product. Just because you would not buy it, does not mean that it should not be produced.

Now I'm no electrical engineer, but couldn't you make the bumps in the road produce electricity with just some sort of piezo electrical material between the spring and the perch on all 4 corners? Sure it wouldn't produce as much power as something like this, but it would cause no problems when/if it failed and could be implemented for a few bucks on any car.