New Zealand Man 3D Prints An Aston Martin

A few weeks ago, we ran a post about a new computer driven tool developed by Ford that allows them to rapidly prototype sheet metal parts. At the time, I raised the potential that Ford’s Freeform Fabrication Technology might have for enthusiasts working on customizing or restoring cars. Load a sheet of metal in the frame, load a file on the computer, and watch it hammer out a fender for your classic or custom car. Apparently that wasn’t much of a stretch. Engadget reports on a New Zealand man named Ivan Sentch who is using an $800 desktop 3D printer to fabricate the body for a 1961 Series I Aston Martin DB4 replica he is making.

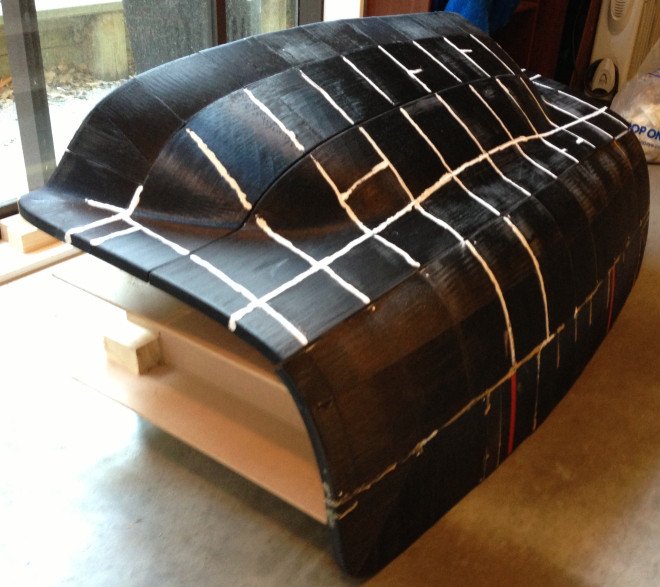

Technically speaking he’s not solid printing the actual car body, that’s going to be made of fiberglass, pulled from a mold made from a buck. A buck is a reproduction of a body in wood to which panels can be shaped or from which a mold can be made. It’s the surface of the buck that he’s printing. Bucks have been used since carriage making days, so Sentch is using an interesting combination of new technology and old school body making. What makes the project even more amazing is that his home 3D printer, a Solidoodle 2, can only make pieces as large as 150 by 150 by 150 millimeters, so Sentch is slowly covering the wooden framework of the buck with those small pieces. Think of it as a rather large 3D jigsaw puzzle. He started with the back deck, the “boot” as he calls it. One the buck is fully skinned with the 3D printed segments, Sentch will smooth everything out and use it to make the female body mold. It’s really a rather impressive accomplishment.

The finished body will hang on the bones and muscles of a Nissan Skyline GTS25T donor car. The wheelbase is right and it should give the final product sufficient performance. Sentch already has used the same engine in a Ferrari 250 GTO replica that he finished before starting on the Aston Martin project.

According to the blog he’s keeping to record the build, Sentch currently has the “body” 72% printed, and a bit more than halfway assembled.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can dig deeper at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Ajla A union fight? How retro 😎

- Analoggrotto Finally, some real entertainment: the Communists versus the MAGAs. FIGHT!

- Kjhkjlhkjhkljh kljhjkhjklhkjh *IF* i was buying a kia.. (better than a dodge from personal experience) .. it would be this Google > xoavzFHyIQYShould lead to a 2025 Ioniq 5 N pre-REVIEW by Jason Cammisa

- Analoggrotto Does anyone seriously listen to this?

- Thomas Same here....but keep in mind that EVs are already much more efficient than ICE vehicles. They need to catch up in all the other areas you mentioned.

Comments

Join the conversation

How long before someone prints something like a Landstalker from GTA, and puts it on a donor Suburban chassis? ;) No copyright infringement there, cause it's not a real car.

I'm fascinated by the long-term implications of this, especially for fans of esoteric but not ultra-rare classic cars. Got a Studebaker you need a fender for? No problem, just find one person with the same year and body style and intact sheetmetal, 3-D scan theirs, and print out the pattern to make a new one. Or to apply it to a wider audience, imagine getting into an accident and the local body shop simply downloads the patterns for the non-electronic parts and fabricates them on-site. This could reduce the need for parts inventory and ultimately reduce the cost of these parts since places like NAPA could stock raw materials locally.