Chrysler-Roush Gemini Engine, Conceived in Auburn Hills, Born in Livonia, Killed in Stuttgart

Two or three times a year, Jack Roush’s Roush Collection has an open house. The Collection is the private museum where Roush keeps many of the race winning cars from what is now Roush-Fenway Racing as well as cars and artifacts from his personal collection of cars, motorcycles and airplanes (the “Cat in the Hat” must have nine lives indeed because the guy has survived two plane wrecks). Since they bring in tables for merchandise and memorabilia to sell during the open house, some of the items in the museum get moved around. Up against the back wall were a bunch of engines, race and prototype, from various projects or race cars. I was admiring one of Jack’s beloved flathead Ford V8s and nearby noticed an odd looking V4, banded to a pallet, with just a tag that said “Gemini engine” and instructions to send it to the Roush museum, with a couple of names after “Attn:”. One of the names was that of a senior Roush engineer.

Did I call it an odd looking V4? Doesn’t that belong in the Department of Redundancy Department? All V4s are kind of odd looking, at least as far as cars are concerned. The blond stepchildren of the car world (I’m a redhead). There have been a few V4 motorcycle engines, including the killer ‘half an LS’ from Katech (they also built the LS based V16 for the Cadillac Sixteen concept), but offhand outside of the Ford V4 used in Europe (and in Saabs) in the 1960s, Lancia’s narrow angle V4s from the 1920s to the 1960s, and in Murilee Martin’s beloved Zaporozhets, it’s an engine configuration that you just don’t see that often in cars or trucks.

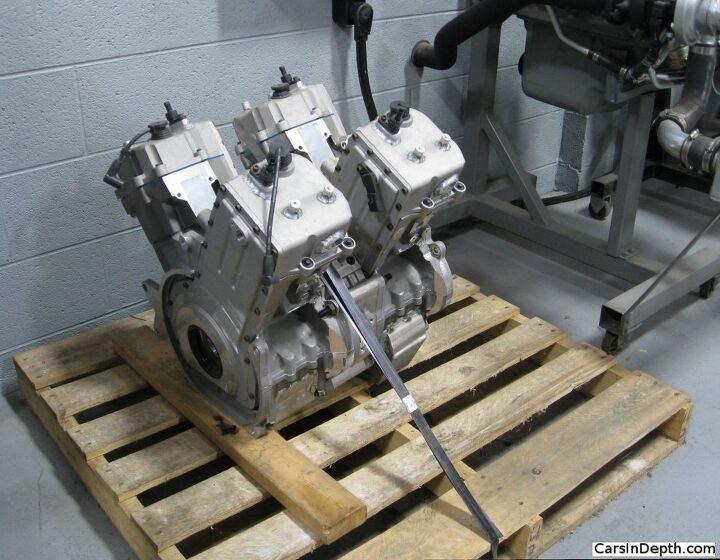

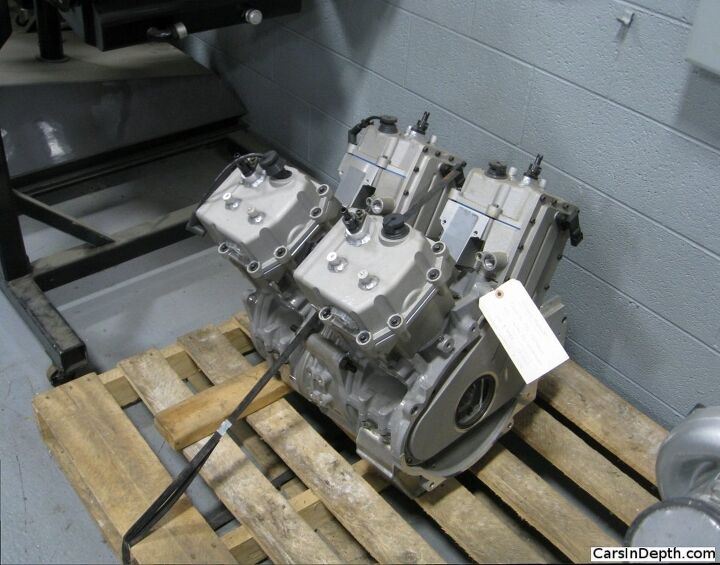

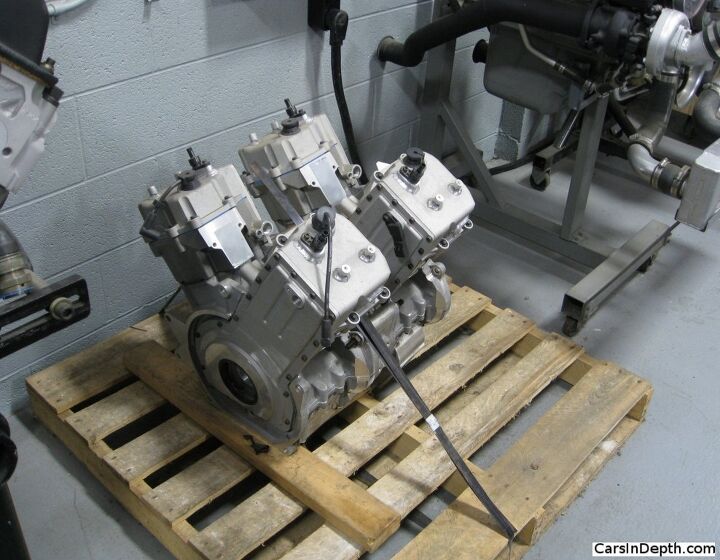

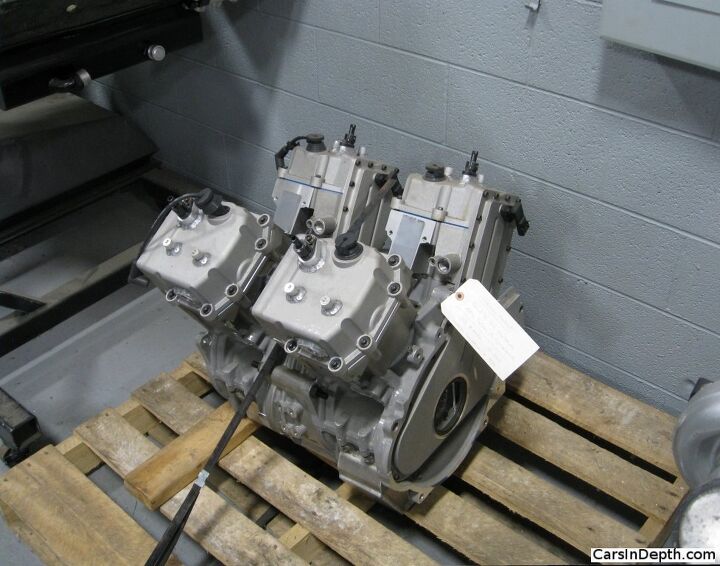

Even for a V4 it was unusual, since it didn’t appear to have the cylinders in a common engine block, each cylinder was separate. To be honest, I thought it was a motorcycle engine and that it looked a little like the engine for the Harley Davidson VR1000 sportbike, a bike that wasn’t terribly successful but ultimately led to the creation of the H-D Revolution engine used in the V-Rod. Roush had worked on the VR1000 engine so it made sense. While processing the photos from that day, I jotted down the name of the engineer and through LinkedIn or something like it, I was able to contact him. Though coincidentally some of the people who worked on the Gemini project had also worked on the VR1000 motor at Roush, he told me that the two projects were in fact not related.

The Harley Davidson VR100 V-twin engine looks a little like the Gemini engine but the engines are not related.

Chrysler had an advanced powertrain program starting in 1989 called Liberty (unrelated to the SUV with the same name) and Roush was one of their primary contractors. That may surprise you because the name Roush is generally associated with Ford. The Roush racing teams have always raced Fords with a variety of series and sanctioning bodies and they are known for the high performance Roush Mustangs they sell. Jack Roush started out as a Ford engineer who liked to drag race, which led to having an engine shop, which he then built into an industrial empire that stretches across Livonia, Michigan. The truth is that Roush does business with all three domestic manufacturers and more than one car company that’s headquartered outside the United States. I’ve seen executive-used Fiat Abarths getting CPO level reconditioning prior to auction sale at one Roush facility and a Mazda 3 with mfg plates in the lot at the Roush Mustang build facility. At the large facility where Roush assembles (to order) the Drag Pak Challengers that compete in NHRA SuperStock with COPO Camaros and Cobra Jet Mustangs (Roush used to build the Cobra Jets in the same building but Ford now has a different contractor doing the final assembly), there was pallet upon pallet of brand new GM V6 engines, about 3,000 I was told. Apparently, GM caught a manufacturing defect, the result of one bad part, before the engines were installed in cars. Roush’s job is to take the engines apart so they can return the constituent parts back to the engine plant for reassembly.

So it’s not really a surprise that Roush has done work for Chrysler, including engine development. You may think that the Belchfire V8 (or today maybe the Hopes-And-Dreams Hybrid Drivetrain) under your hood was designed by the company whose brand is on the car but a lot of engineering work gets jobbed out to companies like Mahle, AVL, and Lotus. In Detroit, Roush gets a lot of that sort of work. For example, the engine at the heart of the Ecomotors startup may have been designed by Ecomotors engineers, but they’re developing it at a Roush facility.

Sp here’s the story: More than a decade ago, as part of their Liberty advanced drivetrain program, Chrysler contracted with Roush to work on a modular V4, essentially two V Twin modules hooked together with a clutch between them. The name Gemini came from the twin modules. The idea was to effect cylinder deactivation without the pumping and frictional loses associated with conventional variable displacement engines by completely shutting down one module. The two modules did share common coolant and lubrication systems so the shut down engine would always be at operating temperature. According to my source, the engine ran fine and met all the test criteria.

Publicly, Daimler-Chrysler CEO Dieter Zetsche praised the 50 member Liberty team, “I am always amazed at the amount of innovation this small group creates.” Privately, Daimler stepped in and essentially told the folks in Auburn Hills, “Ve haf a development team in Chermany,” and killed the Gemini project as well as the entire Liberty program. What could have the Liberty have meant for, say, the Caliber, which was certainly done no favors by its “world” engine? We’ll never know.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can dig deeper at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

The unrelated Harley Davidson VR100 V-twin engine.

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Redapple2 I love my geolander by yokohama. Wild Peak are almost as good.

- Redapple2 Why is a mexico BYD china car BAD -End of the World! But > gm < Buick Envision good (build more !) ?

- Kwik_Shift_Pro4X Supporting EVs is supporting Chi-nah.

- Eliyahu Oh, a nicer looking 2025 Camry!

- Analoggrotto Sell Canada to Mexico.

Comments

Join the conversation

I need that engine for my Harley.

Diamler had previous experience with a clutched dual engine install. See DB610. The results were quite illuminating during night ops.