Behind The Scenes: General Motors Production Build Center – Building the LS9 Engine

When Bertel Schmitt launched TTAC’s Behind The Scenes series with an exclusive and in depth look at Toyota’s high-tech LFA Works, I thought to myself, “Self, you live in Detroit. Lots of automotive scenes to get behind in and around this area.” So, following up on Bertel’s idea to use the access TTAC affords us to give you a look at things you might otherwise not experience, I sent an email to someone in communications at GM about their Performance Build Center in Wixom, MI.

The GM PBC is a small factory where about two dozen high skill employees hand build many of GM’s highest performance engines, primarily the 505 HP normally aspirated LS7 used in the Z06 Corvette, and the supercharged 638 HP LS9 that goes in the ZR1 ‘Vette (the supercharged LSA fitted to Cadillac’s CTS-V models, which slots in between the LS7 and LS9 in terms of power, is assembled in Mexico). The PBC also builds crate versions of those motors as well as the dry sump equipped LS3 for the track oriented Grand Sport edition of the base Corvette, and it will be assembling all 200 or so engines that will be available in the 69 non-street legal COPO Camaro drag cars they are selling (each COPO car can be ordered with up to three engines to match various NHRA Stock Eliminator and Super Stock classes).

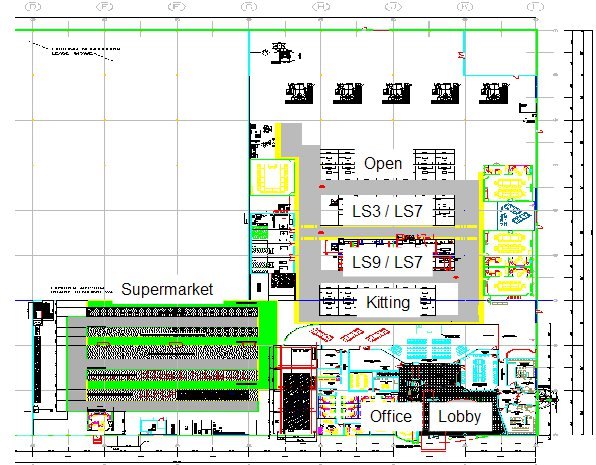

The facility has been building engines since 2005, and was designed as a showcase facility, using AMG’s engine plant and Hendrick Motorsports’ engine shop as benchmarks. GM says that it’s a unique facility, not really matched by any other large car company. Large automobile manufacturers make engines by the millions, not short runs of essentially hand built components. When a large manufacturer needs a relatively small number of specialty engines built, they usually turn to an outside firm. In Bertel’s LFA series, he points out that the V10 in that car is actually assembled by Yamaha, who also supplied Ford with the original Taurus SHO V6. Even the Lotus-designed LT5 in the previous C4 based ZR1 of the early 1990s (GM had control of Lotus at that point in time) was assembled for Chevy by Mercury Marine. Some car companies do build hi-po engines in house, Ford built the Ford GT’s V8 at their Romeo, MI engine plant and Volkswagen builds the Bugatti Veyron’s W16 at VW’s engine facility in Salzgitter, Germany. While of course there are dedicated assembly lines and particularly skilled workers involved, those are both huge factories. The GM PBC has three small lines of 15 stations each. I was told that it’s GM’s most “flexible” facility. One line currently builds LS7s and LS9s, another line does the LS7 and the Grand Sport’s LS3, and the third line is “open” and currently used for COPO builds not done by customers and some special builds The shop floor also has an area where component kits for specific engine builds are put together, and a “supermarket” where parts and subassemblies are kept in inventory. The 100,000 sq ft plant has an annual capacity of 15,000 engines, a small fraction of the engines a typical automaker’s engine plant can produce. If needed, there’s a railroad siding out back. I’m not sure exactly how the GM PBC differs from AMG’s Affalterbach facility, from which the GM PBC borrowed the “one man one engine” assembly method, but GM says that the PBC is one of a kind. Perhaps the distinction is that AMG was an independent company acquired by Daimler while the PBC has been an in-house project at GM from the get go.

General Motors Performance Build Center floor plan

In Detroit there are skilled trades and then there are skilled trades. While the guy who plugs in your machine in the factory where you work could have the job classification of an “electrician”, you still might not trust him to wire your house. The UAW members that build the engines at the Performance Build Center are indeed about as highly skilled as you’ll find working in industry. Most have, on their CVs, experience with hand building experimental and prototype engines in GM’s Pontiac pilot facility and at the Warren Tech Center. While there were one or two short timers when I was there, to be considered for a long term job building engines at the PBC, regardless of their prior experience, workers still have to first pass an apprentice test. So the facility is a combination of high tech and old-world style guild craftsmanship. The people who work there seem to be very proud of being associated with a world-class facility.

AMG’s Affalterbach engine shop has visitor tours, though they don’t allow photography. Since it was built to serve in part as a showcase, a couple of years ago someone at the PBC got the great idea that not only was it a cool place to show off to the media, they could also show it off to customers though GM went AMG a step or two beyond just letting you take some pictures. They started the Corvette Engine Build Experience for any customer buying a Corvette equipped with one of the PBC engines and have since expanded it to crate motor and COPO customers as well (if they want to, COPO buyers can build all three engines they buy). Of course it’s not free. GM charges $5,800 for the “experience”.

When a customer builds an engine they have options from just standing there and watching an expert technician build their motor to pretty much putting in every part and torquing every bolt and everything in between. You’re scheduled to arrive at 7:00 AM. If you don’t do much, you might be done by early afternoon. If you do a lot of the work, like to talk, ask a lot of questions and are busy taking pictures and shooting video for TTAC, it can take most of the day. That means that on a Build Experience day the aforementioned highly skilled worker only “builds” one engine that day instead of two or three.

One cost that GM doesn’t have to worry about is an incompetent customer building a crappy engine. The plant’s normal quality control and testing procedures are impressive and designed around consistent and uniform high quality. Every fastener’s torque is applied with a computer controlled device and those torques are logged by the control system. Bar codes are used at every step of the process. If something hasn’t been tightened properly, the system knows it. If too few bolts were fastened the system knows it. If too many bolts are fastened, it has to be accounted for. When everything is copacetic, the panel on the bar code reader flashes a graphic of Jake, the Corvette mascot, in green and you can proceed to the next station. Fixtures are used when alignment of parts, like the dry sump oil pump, is critical and in one case a runout gauge is used. Add in good instruction plus continuous very close supervision and providing you know which end of a socket goes on a bolt, the engine a customer builds should be as powerful and reliable as any that come out of the PBC. I’m not saying that a trained monkey could do a customer build, and “idiot proof” is a crude way of characterizing the sophisticated QC systems in place, but in a sense the PBC is gilding refined gold with the skill of the assemblers during normal production.

Though they don’t do a full throttle gasoline powered power and torque test on each engine, during the build at a couple of points torque needed to spin the engine is measured to make sure that internal friction is within tolerances and the almost assembled engine is also tested with air pressure to make sure that there are no leaks in the cooling and lubrication systems. Once competed, the engine is filled with oil and coolant for a cold spinning test and then it’s run, powered by natural gas, on a dynamometer in a test cell during the final harmonic balancing. As mentioned, that’s not a full gasoline fired dyno test, but it is used as a final check to screen out engines with anomalies before shipping. Assuming everything checks out, most of the engines built at the PBC are shipped to the Corvette assembly plant in Bowling Green, KY, where they will again be tested, once installed in a Corvette, on a chassis dynamometer. The customer built engines come with the identical warranty as any of the other engines produced by the facility. In addition to all that testing, the engines are not just rated under SAE test procedures, the plant is “SAE Certified”, which means that GM is effectively guaranteeing advertised power ratings.

While five or six grand for a one day event isn’t cheap, GM isn’t exploiting anyone, and the revenue probably comes close to the cost of the program. Based on my own experience and the fact that the actual customers are likely to already be Corvette fan boys and girls, I don’t think that they’ll be having any dissatisfied customers. About 50 customers have built engines so far, and paying participants get their picture on the PBC’s wall of fame, plus, I’m guessing, some cool swag. GM also supplies lodging, food and ground transportation, everything but transportation to the Detroit area.

As a car guy living near Detroit, I know that a lot of people, including many Americans, think that the entire Detroit area is an actual, not virtual, hellhole filled with the indolent, lazy, stupid and talent-challenged, but like Peter DeLorenzo likes to say, there are still plenty of true believers with plenty of smarts, talent and a personal drive to make great cars in this town. The GM Performance Build Center appears to be staffed by some of those true believers.

Disclaimer: GM let me participate in the Engine Build Experience and bought me a vegetarian salad and a root beer for lunch. Oh, and a Pepsi. I provided transportation. I did get one of Mike Priest’s “assembled with pride” plates that gets attached to each engine he builds. Actually, as I applied the plate to the side of the intercooler housing per the placement fixture Mike had set in place, I asked him if I might be able to have one as a souvenir. He smiled and took the one out of his shirt pocket that he’d already gotten for me. I’m guessing that for their $5,800, actual Engine Build Experience customers also get a shirt and some swag. That and a very cool, very powerful engine.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can dig deeper at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- SCE to AUX Range only matters if you need more of it - just like towing capacity in trucks.I have a short-range EV and still manage to put 1000 miles/month on it, because the car is perfectly suited to my use case.There is no such thing as one-size-fits all with vehicles.

- Doug brockman There will be many many people living in apartments without dedicated charging facilities in future who will need personal vehicles to get to work and school and for whom mass transit will be an annoying inconvenience

- Jeff Self driving cars are not ready for prime time.

- Lichtronamo Watch as the non-us based automakers shift more production to Mexico in the future.

- 28-Cars-Later " Electrek recently dug around in Tesla’s online parts catalog and found that the windshield costs a whopping $1,900 to replace.To be fair, that’s around what a Mercedes S-Class or Rivian windshield costs, but the Tesla’s glass is unique because of its shape. It’s also worth noting that most insurance plans have glass replacement options that can make the repair a low- or zero-cost issue. "Now I understand why my insurance is so high despite no claims for years and about 7,500 annual miles between three cars.

Comments

Join the conversation

Very good article, Mr. Schreiber. Hats off to GM for trying this. Its good to see they are willing to try different things. I shudder to think what this took to get it approved - legal and insurance alone (someone could be injured ! oh, the horror!) What I find curious is that only about 50 people have taken advantage of this. You would think that anyone that could spend $100k on a vehicle with little practical value (you don't see soccer Mom's shlepping kids around in too many Vettes) wouldn't bat an eye at shelling out for this experience. If I had that kind of money laying around, you bet, I would be off to put my engine together.

@ajla-I can vouch for 25 minutes alone with an LS7 being an incredible experience! I have a fairly hot LS6 and it is a child's toy in comparison. The naturally aspirated torque is always their and it hits 60 in first gear with 7,000 RPM! I have been limited to 159 at grounds and on expressways, but it was still pulling very strongly. I hope the C7 brings the prices down (a lot!).