Memoirs Of An Independent Repair Shop Owner: My Formative Years Wrenching on British Steel, Or: How Whitworth, Lucas, Girling and Other General B.S. (British Standard) Set Me On a Skewed-And Stimulating-Career Path

“We don’t need mechanics…we need MAGICIANS!”

In a heavy accent loaded with London grit, that was the response of the proprietor of the local—and at that point in time, quite vital—independent British Car garage, when I approached him to inquire as to whether he was in the market for hired help.

Not even twenty years of age, with a whopping one-year’s worth of experience servicing used cars for a BMC/Jaguar/Toyota dealership, just up the Pacific Coast Highway, I was still in the process of formulating an opinion as to what it took to make a success of wrenching (or should I call that “spannering?”) on things British.

I hadn’t yet appreciated the truthfulness of the point he was making; but I detected a seriousness veiled by his Shakespearean theatrics.

After less than another year, though, I fully understood “The Crux”: British repair shops had the virtually impossible mission of rendering as reliable transportation—in a vastly different set of circumstances than in their country of origin—basically flawed vehicles with an equally flawed support infrastructure.

Although there have probably been many BOOKS written on this very subject, I think I could throw my “hat in the ring” without being completely redundant. There is just so much material to work with —the people involved and the cars themselves, not to mention our specific locality— that, although there is certainly a common thread, there have to be many valid and interesting points-of-view on the subject, including mine.

Due to the nature of our format, I’ll only be able to relate a couple of noteworthy experiences in this entry that tend to prove my point.

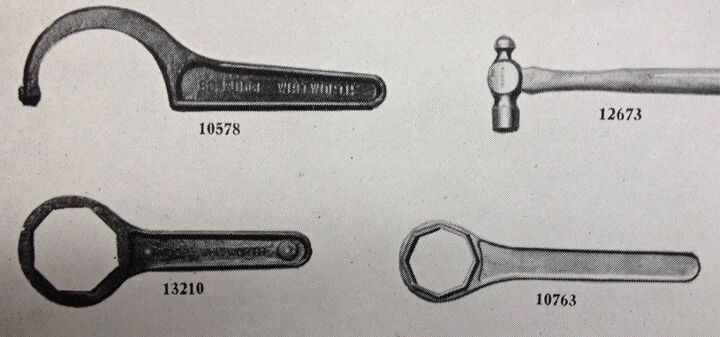

The first involves the actual hand tools needed to work on these cars.

The fasteners and plugs used were neither Metric, nor SAE, but of a design that may have predated either, or at least were developed at a concurrent time: WHITWORTH.

All I knew, in my fledgling days of working on autos for pay, was that most of my paychecks were going towards the purchase of hand tools; and NOW, besides needing a proper set of BOTH Metric and SAE wrenches and sockets, I was going to have to purchase a THIRD SET of the British-Size-In-Between!!

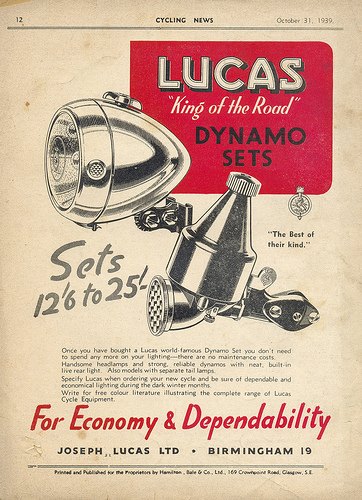

Many things have been said in jest about Lucas Electrics, and if not absolutely true-to-the-letter, are certainly true in spirit. I have seen problems with creations from the so-called “Prince of Darkness” that I have not seen ANYWHERE else!

Take, for example the “78 MGB that had to be pushed off the Delivery Truck and rolled onto the New Car Lot at the dealership I was then employed by. That in itself was not completely uncommon, even for one of the Toyota models, which were becoming known for reliability by that time. Typically a battery recharge or the addition of a little more gasoline would clear up such a problem.

But THIS was something “Other”, so a few of us underlings got the privilege of pushing the “B” into my tech neighbor’s work bay.

By definition, he was considered a PDI (Pre-delivery Inspection) tech; but PDI on British Cars often involved CONSIDERABLY more technical “chops” than those needed for Toyota PDI.

In proof of this, within a couple of days, he had determined that it would not be cost effective to repair the existing Main Wiring Harness, and he had the old one removed for replacement. Of course, when the new one arrived and was installed, the best that could be said about IT was that it was going to actually BE cost effective to repair! About a week later, all was sorted, and the brand-spanking-new “B” was ready for sale!

Another feature of these late-‘70’s British Leyland products was their electronic ignition systems.

Apparently not wanting to spoil their reputation for unreliability, Lucas managed to produce a distributor-mounted “amplifier” (module) that couldn’t seem to outlast a set of points found on the old-style distributor. Replacement units didn’t seem to last any longer, so eventually the repair procedure —and we’re talking about the dealer’s repair procedure— was to replace the entire electronic distributor with an earlier-style contact points model!

When Lucas finally decided to get into the Electronic Fuel Injection arena, they teamed up with Robert Bosch—maker of really good electrics and electronics found on European vehicles down to this day. Unfortunately, due to the hyphenation issue created from this union (Lucas-Bosch) the resulting systems proved to be only half-good.

One of my memorable discoveries—and there were many—was the design of the conduit tube connecting the Airflow Meter to the Throttle Body on some models, including the TR7. It was constructed of what appeared to be a glorified form of “Tar Tape” (used to wrap wiring harnesses on early-model vehicles), wrapped around a thin-wire coil structure. Of course, the Tar Tape would deteriorate in short order, resulting in acceleration “flat-spots” initially—and eventually and engine that would not run at all. Since the replacement units were expensive, of the same design, and often unavailable (due to popular demand), I got good at rewrapping the tube with fresh Tar Tape.

Then there was the hydraulics these cars were equipped with.

I can say that I got a LOT of experience rebuilding clutch and brake Master Cylinders, wheel cylinders, and calipers (this was when “rebuilding” such units was not legally objectionable). No matter how good a job I—or anyone else—did, they’d be leaking within a year or two, and I’d get to do it all over again. Sure, it was job security, but of a temporary nature, as such levels of “routine maintenance” were becoming a thing of the past on vehicles of Other Manufacture.

Were only scratching the surface, as it were, with these stories. If there’s a demand, I’ll be happy to provide more.

Phil ran a successful independent repair shop on the West Coast for close to 20 years, working over a decade before that at both dealer and independent repair shops. He is presently semi-retired from the business of auto repair, but still keeps his hand in things as a consultant and in his personal garage.

More by Phil Coconis

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jeff Good review but the XLT although not a luxury interior is still a nice place to be. The seats are comfortable and there is plenty of headroom. The main downside is the limited availability resulting in dealer markups above MSRP. I have a 2022 hybrid Maverick XLT for over 2 years and it has more than met my expectations. I believe for many who do not need a truck most of the time but want one the Maverick will meet their needs.

- Kwik_Shift_Pro4X I use a now discontinued Kuhmo AT tire that is surprisingly good in the snow, even in 2WD. However since most of my driving is on road, I'm going to look for a more highway friendly tire for smoother quiet. I'm sure it can still handle the forest roads leading to my fishing spots.

- MaintenanceCosts So this is really just a restyled VW Fox. Craptacular tin can but fun to drive in a "makes ordinary traffic seem like a NASCAR race" kind of way.

- THX1136 While reading the article a thought crossed my mind. Does Mexico have a fairly good charging infrastructure in place? Knowing that it is a bit poorer economy than the US relatively speaking, that thought along with who's buying came to mind.

- Lou_BC Maybe if I ever buy a new car or CUV

Comments

Join the conversation

I'm amazed that anyone, let alone a shop owner would think that Whitworth tools were necessary for 1970s era British cars. Whitworth was pretty much phased out following the MG "T" series ara in the mid 1950s. The vast majority of threads became the same as the American NC and NF series. Of course the people who want to sell you expensive and unecessary tools have a slightly different take on this...

Usual rant about Lucas, when really, the blame should be put squarely on the shoulders of people like BMC, Triumph, Rover and Standard. Rootes didn't seem too bad, and Ford and GM in the UK had no problems to speak of. Lax standards, nobody in engineering charge except for flighty types like Issigonis at BMC. I mean, c'mon, the distributor for the Mini and 1100/1300 was right behind the grille where it stopped the rain from hitting the engine! When I went to England in 1969 for an extended stay, there were cars stopped at the side of the road after every rain storm. ALL of them were BMC models, most the above two models. Then someone had a brainwave and a rubber covering was put over the distributor. Fine in the rain, but bad in humid weather for condensation and the usual result. You can go to Curbside Classics where there is a reasonable article on Lucas. The author says the Lucas stuff itself was well made, but that didn't stop people using it in dumbass fashion. Whitworth threads? See TR4 above.