Memoirs Of An Independent Repair Shop Owner: How Honda's CVCC Gave Me My 10 Best Years-Part Two

There are those times when some truths seem so apparent, one would think they would be that apparent to others. Of course, that isn’t always the case; which is why historical eyewitness reporting often results in a very different accounting of events. That isn’t to say that every report is necessarily “the truth”, even if there is that conviction on the individual reporter’s part.

Since this is an editorial column, I really can freely spout off opinions on any subject without ANY level of objectivity, if I’m so inclined. But that’s not the way I roll, which is why I think this site is a very appropriate place for my postings.

That being said, I’m going to provide some additional evidence to support my statements in (what can now be considered) Part One.

It’s not my intent to turn this into some sort of an unsolicited testimonial for the Honda Motor Company; in fact, I’m making a conscious effort to avoid this sort of thing in ANY of my entries. Nevertheless, I have to call it as I see it—and I certainly did have an excellent vantage point, with my hands-on experience on many different vehicles from the period that is the basis for our dialogue.

When I consider what other manufacturers were producing during this period, I am not experiencing any warm and fuzzy feelings about spending time under their hoods.

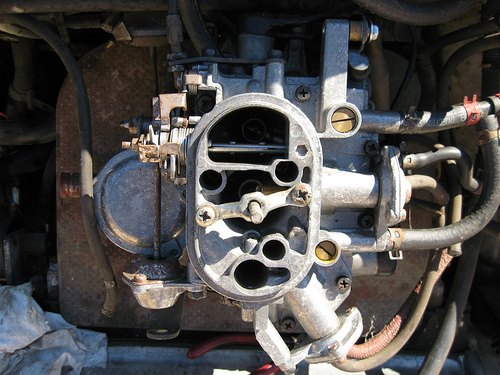

Carburetors—ANY carburetor—from this period were generally just appalling, for the most part: The Blue Oval’s Feedback Variable Venturi, The General’s CCC, The Five-Point-Star’s Feedback Holley-Weber, to name a few. All a distant memory, thank the Car God’s! Yes, the European use of the Continuous Injection System was one of the bright spots, having replaced their by-and-large hideous emission carburetors preceding it.

But the Honda’s CVCC carburetor was really a REVELATION! It’s basic design didn’t change fundamentally from its introduction all the way until the end of the CVCC engine’s run. Yes, there was the 1983 CVCC Prelude—a one year only offering—with its dual sidedraft carbs, but otherwise we techs had only one design to familiarize ourselves with.

Honda never went to any sort of feedback mixture control variant (the feedback control they later added was an air-bleed system outside of the carb), or any other technology that made servicing the carb more difficult and expensive.

Techs could service the carburetor on-car; Honda even provided what they called an “On-Car Repair Kit”, containing all of the essentials for performing this service. It was a very rare occurrence that this carb had to be removed for repair. I NEVER had occasion to actually be required to replace one! There were a couple of instances where, if going by the factory recommendations in the service manual, I SHOULD have replaced the unit, but having a deeper grasp of the actual engineering and principles of operation, I was able to make a viable repair, instead.

Yes, it’s true that these carbs did have an “Achilles Heel” in the form of what seemed to be rather expendable floats (they had two, one for the main chambers and one for the auxiliary chamber). I think the failures might have had something to do with the changing fuel formulas of the time. At any rate, they eventually got it right. The shops I worked for at the time gave reduced rates for the float replacement procedure; and we didn’t mind, because it was so easy for us to do.

Some techs complained about the degree of difficulty involved in the removal of the air cleaner assembly for this procedure, but compared to some other imported cars of the day, I didn’t find it that big of a deal.

Regarding the CVCC cylinder head servicing, when it came to the servicing of the Auxiliary Valve / Prechamber unit, us full-time Honda techs didn’t have a problem with it, either. Throughout the years, we could do what we called a Prechamber Overhaul with pretty much the same minimal set of special tools. There weren’t a bunch of new additions required with each successive model year.

Some complained about the frequency of headgasket problems with these engines, but as far as I could tell, poor design was a factor on only the earliest models. Otherwise, headgasket failure was just collateral damage inflicted by some other cause: loss of coolant through some cause other than the headgasket itself, poor owner maintenance (failed thermostats, radiator fan switches, broken water pump belts, failed water pumps—usually due to over-tightened belts or poor coolant maintenance, etc.).

It’s also true that, on earlier models, Honda engineers had the radiator fan switch supplying the high-amperage current to the motor—which did cause rather premature failure of the switch. I engineered a relay system where the switch only controlled the low-amperage current in the relay solenoid circuit, resulting in big-time longevity for these otherwise overloaded switches.

Regarding the vacuum system on the CVCC engines: yes, they did get quite complicated on later models, but I found them to be very reliable, and not really that difficult to service. Often, serious difficulty was almost always caused by a previous encounter with an inept and impatient “tech”.

The underhood vacuum schematics were very easy to follow, and the hoses were numbered and color-coded, not to mention the fact that they were made out of an incredibly durable rubber compound.

Savvy techs made it a point to only remove hoses for other service when absolutely necessary—an then using the right technique to avoid damaging the hoses, steel tubing or components. We generally left everything connected when removing cylinder heads. The whole removed assemblage of head, manifolds, carb and vacuum system was still relatively light, so again, it was no big deal to do it this way.

I could go on and on with more reasons why it was a real pleasure working on these cars during this period (did I mention that—along with the Catalytic Converter—there was no EGR system to deal with until the early ‘80’s, too?), but I’m hoping my point has been defined and clarified a bit better than at the end of the first part.

Other car companies may have had the ability to do what Honda did, but only Honda actually DID it, for which I’m very grateful, indeed.

Phil ran a successful independent repair shop on the West Coast for close to 20 years, working over a decade before that at both dealer and independent repair shops. He is presently semi-retired from the business of auto repair, but still keeps his hand in things as a consultant and in his personal garage.

More by Phil Coconis

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Michael S6 Very confusing if the move is permanent or temporary.

- Jrhurren Worked in Detroit 18 years, live 20 minutes away. Ren Cen is a gem, but a very terrible design inside. I’m surprised GM stuck it out as long as they did there.

- Carson D I thought that this was going to be a comparison of BFGoodrich's different truck tires.

- Tassos Jong-iL North Korea is saving pokemon cards and amibos to buy GM in 10 years, we hope.

- Formula m Same as Ford, withholding billions in development because they want to rearrange the furniture.

Comments

Join the conversation

I still drive a 4-speed 77' Civic CVCC wagon. Don't drive it daily, but it's my only car, so she sees the road a few times a week. I've heard the carbs are tough to rebuild, haven't tried ti myself yet, but will in time. I'll be doing the headgasket sooner than later too, got a leak there that will lead to bigger problems. But she passed California emissions testing a few months ago, so she's still good in that regard. Only difficult thing is trying to find parts.

I was a young mechanic in 1978 and worked for a Pontiac/Honda dealership in Falls Church. I had just passed my NIASE certifications for all 9 areas (engines, electrical systems, air conditioning, transmissions etc.) and my shop manager sent me to the Honda School in the Cherry Hill area of NJ, for all the different courses they offered on Honda cars, including CVCC engine rebuilds. at that time there was a major recall for a defective head gasket that would leak antifreeze into No. 4 cylinder. The recall involved at a minimum replacing the connecting rod bearings, the head gasket, piston rings, and is the leak was bad a complete overhaul of the engine. I was doing 3 of these rebuilds a week. Between 1976-77 there were some 300,000 CVCC engines under the recall. They paid 5.6 hours for the recall and it took 8 hours to complete. On the other hand the 1978 Accords and Civics did not come factory equipped with air conditioning. In the Washington DC area summers are God awful hot, so Honda AC kits were selling like hotcakes. It would take four hours to install an R-12 ref. system and the pay was 12 hours. So what we would loose in the CVCC engines we'd make up for in the AC kits. The carburetors were unbelievable. No one was good at rebuilding them and they were particularly sensitive to dirt and water in the gas. The filters were not that great so the float bowls would collect debris. The carb was ingenious, really two in one. There was a two barrel for the main chamber feeding a rarified 23:1 air gas ratio. Then there was a pre-chamber carb built into the carb. This fed a rich 5:1 air gas ratio to the small steel cup "prechamber". The prechamber ignited with a spark plug and would torch into the main chamber. The carb had a complicated system of vacuum lines that controlled various servos etc. If you didn't get the right hose on the right vacuum port the car wouldn't work right. Mechanics that didn't know what they were doing could really screwed up the carburetor. On the 1978 model Honda got the bright idea to control hydrocarbon emissions from the float bowl by placing vacuum operated plugs to the float bowl vent. If the vacuum lines to the valve mounted on the firewall was accidentally switched the vacuum would be cut from the plugs and the float bowl was not open to atmosphere. When the line was switched the car wouldn't go more than 10 mph, backfired and ran in wild fits and starts. One new mechanic got a car that had been serviced by a local shop. The mechanic had switched the line and the Accord acted like there was something majorly wrong with the engine.Those damned carbs used steel screws to bolt the top on (about 14 of these tiny screws). The bi metal condition (electrolsis) would corrode the screws in the float body and they'd snap. This guy must have snapped half the screws. After three days of rebuilding the carb, and replacing it with two new carbs, the car wouldn't run any better. Being the young guy in the shop I usually kept a low profile, but after 3 days of getting nowhere and no with about 5 "top" shop mechanics crowding around the car I came over too to take a look. The week before I had taken a Honda air emissions control systems course and noticed that the vacuum line to the servo on the firewall was swapped onto the wrong nipples. I switched them and said, try the car. It ran like new. This guy had the car 3 days , ruined on carb and replaced two new carbs and all it was was a switched vacuum line. This design was particular to the 1978 CVCC engines. God the air lines coming off those carbs looked like a plate of spaghetti. Man do I have stories about my early years as an auto mechanic. At age 26 I went to college for physics and got my MS in Engineering. I pretty much got out of cars. I was never much of a gearhead anyway. But I do look back on those days fondly. Now I'm 66 and look at the possibilities. I'm probably one of the few people left who knew anything about the Honda 1200 cc Civic engines, 1975 1500CVCC engines and the 1600 1976-1978 CVCC engines. Hondas began moving towards fuel injection by around 1980 and used electronic ignition, which reduced the amount of "real" mechanical work to be done. Honda was the kind of motor company that had their mechanics do a lot of their own machine work. I did a lot of machining. The only work I didn't do was machine warped cylinder heads. That work was sent out. Honda even made us mechanics rebuild alternators instead of simply replacing them with rebuilts. We'd actually test the diodes for problems and replace them. We did everything except the windings. That would have been ridiculous. But we did a lot of work with Hondas that most other manufacturers would have their mechanics do. If anyone is having trouble with a Honda CVCC I must have rebuilt 200-300 of them between 1978-1980.