Toyota And BMW Plan To Take The Lead In Commercializing Fuel Cell Cars. Let's Revisit

The intensified alliance between Toyota and BMW shines a new light on a technology that has been discussed for decades, but that never quite made it: Hydrogen fuel cells. BMW will get access to Toyota’s fuel cell technologies. This most likely spells the end of the fuel cell cooperation between BMW and GM. Let’s take another look.

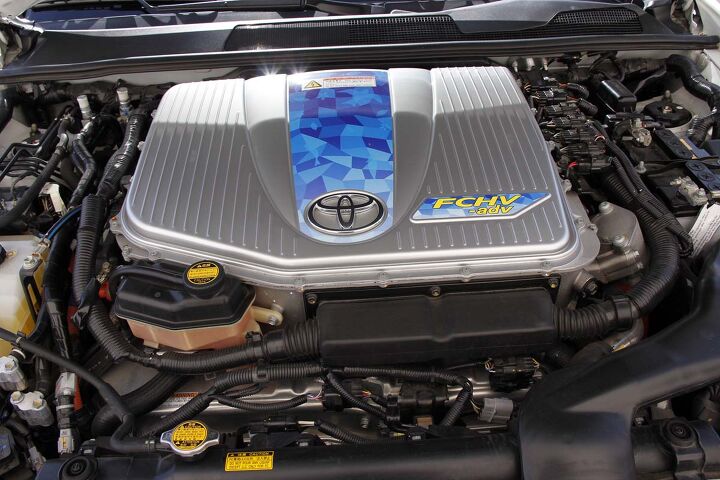

Toyota is far ahead with the technology. The company had Fuel Cell Hybrid Vehicles (FCHV) on the roads for ten years. In 2009, it “launched” its FCHV-adv, basically a Highlander with the hybrid synergy drive from the Toyota Prius connected to a 90kW fuel cell stack. A few months ago, editor-at-large Ed Niedermeyer and I had it on a short test ride through the scenic warehouse landscape of Torrance, CA. Except for an eerily quiet drive, the ride was uneventful.

On a full tank of – this time real – gas, we could have taken it all the way to San Francisco and beyond – no range anxiety here. Fuel cell vehicles have all the advantages of a battery-operated vehicle, i.e. no emissions (the fuel stack produces water), and nearly none of its drawbacks.

If you want to drive tailpipe emission free, your choices are battery, or fuel cell. A fuel cell is basically a battery. Fuel cells and batteries use a chemical reaction to make electricity. When the chemicals in a battery are depleted, you must recharge or throw away the battery. The chemicals of a fuel cell are hydrogen and oxygen. You provide the hydrogen. The fuel cell stack uses free-of-charge oxygen from the air and produces electricity plus H2O – water. Proponents of the technology say that well-to-wheel, fuel cells involve much lower emissions than batteries. Refilling the hydrogen tank should not take longer than filling up with unleaded. Next stop after 400+ miles.

The only way to extend the range of a BEV (if you don’t want to add an ICE) is by adding more batteries. This quickly becomes an exercise in futility. Each added battery cell means more weight, heavier brakes, a larger traction motor, a stronger body to carry the mass, and in turn even more batteries. And most of all, it becomes insanely expensive.

Not so with fuel cells. Fuel cells can make electricity at weights that are between eight to 14 times less than current batteries. Extending the range of a fuel cell vehicle has negligible impact on its weight.

Like electricity, hydrogen is not a way to make energy, it is a way to transport energy. Hydrogen can be made in the same number of ways as electricity.

And why aren’t we all driving around in fuel cell vehicles by now? There were a number of technical challenges, but as Toyota Chief Engineer Satoshi Ogiso had told us last year, the challenges have all been mastered. The only real problem Ogiso is facing with hydrogen fuel cell vehicles is money:

“For us, the only remaining real issue that stands in the way of fuel cell electric vehicles is mass production cost.”

Current fuel cell technology is big, bulky, heavy and expensive. With enough scale, package size and price can come down considerably. Toyota plans to launch a commercial FCV in 2015. It still will be expensive, the Nikkei figures 5 million yen, or $62,000. By 2020, Ogiso plans to have an affordable FCV.

Luxury vehicles are much better for early-tech alternative propulsion, because the cars are big enough to hide the heft and expensive enough to mask the price. With their alliance, Toyota and BMW plan to “take the lead in commercializing fuel cell cars,” as The Nikkei [sub] writes. Says The Nikkei:

“Other automakers are forging ties over green technologies. Daimler AG is rushing to develop a fuel cell car with capital partner Nissan Motor Co. Meanwhile, Honda Motor Co. and Hyundai Motor Co. are developing fuel cell cars on their own. General Motors Co. has been considering a fuel cell tie-up with BMW, but it may have to change course now that the German firm has opted to partner with Toyota.”

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jalop1991 does the odometer represent itself in an analog fashion? Will the numbers roll slowly and stop wherever, or do they just blink to the next number like any old boring modern car?

- MaintenanceCosts E34 535i may be, for my money, the most desirable BMW ever built. (It's either it or the E34 M5.) Skeptical of these mods but they might be worth undoing.

- Arthur Dailey What a load of cow patties from fat cat politicians, swilling at the trough of their rich backers. Business is all for `free markets` when it benefits them. But are very quick to hold their hands out for government tax credits, tax breaks or government contracts. And business executives are unwilling to limit their power over their workers. Business executives are trained to `divide and conquer` by pitting workers against each other for raises or promotions. As for the fat cat politicians what about legislating a living wage, so workers don't have to worry about holding down multiple jobs or begging for raises? And what about actually criminally charging those who hire people who are not legally illegible to work? Remember that it is business interests who regularly lobby for greater immigration. If you are a good and fair employer, your workers will never feel the need to speak to a union. And if you are not a good employer, then hopefully 'you get the union that you deserve'.

- 28-Cars-Later Finally, something possibly maybe worth buying.

- EBFlex The simple fact is very small and cheap ICE vehicles have a range thats longer than all EVs. That is the bar that needs met. And EVs cannot meet that.Of course range matters. But that's one element of many that make EVs completely ineffective at replacing ICE vehicles.

Comments

Join the conversation

The future of fuel cells is Solid Oxide Fuel Cells (SOFC).. these take a hydrocarbon and process it to get hydrogen, then the hydrogen is used to make electricity. My local supermarket has an emergency power supply based on this.. the unit is about the size of a railroad car and runs on diesel (it has internal diesel tanks). The Bloom box is another example, running on natural gas. Some run on methanol and power laptops. The issue with SOFC is that the high temperature they operate at is not well suited for cars, the rapid cycling up and down literally grinds the parts away. Work is ongoing since they dont have the efficiency limitation of heat engines. Platinum is not needed.

Thank you BS for this informative piece. Many people misunderstand the use of Hydrogen in cars as a fuel source and not just a battery replacement. However, I still don't think that pervasive use of FCHV is just around the corner. The discovery in the US and China of ample natural gas reserves will probably mean that wider use of CNG is more likely in the next 10 years than FCHVs.