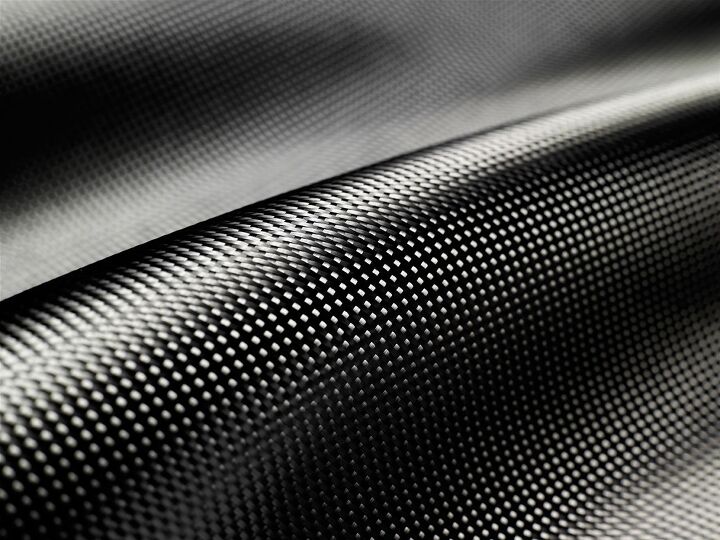

Fiber Fever: Carbon Goes Mainstream

For a long time, carbon fiber was a high tech, high cost product. Slowly, carbon fiber is going mainstream. From Volkswagen to Toyota and GM, large automakers have carbon fiber projects in the works. Now, Ford is joining the bandwagon made from lightweight fiber.

Ford joined up with fiber specialist Dow Chemical “to develop cost-effective ways of using carbon fiber in high-volume cars and trucks as the No.2 U.S. automaker moves to cut vehicle weight to improve overall fuel economy,” Reuters writes.

Shedding weight is one of the most efficient ways to increase fuel economy. If you don’t have to drag around superfluous weight, your car will go farther on a tank of gas, or a fully charged battery for that matter. By 2020, Ford aims to cut between 250 pounds and 750 pounds from its new cars and trucks, partly by using lighter materials.

Using carbon fiber instead of steel can lower the weight of a vehicle component by up to 50 percent, says to the U.S. Department of Energy. Cutting a car’s weight by 10 percent can improve fuel economy by as much as 8 percent.

The biggest problem is cost: These space-aged materials command spaced-out prices. Bringing cost and weight down is the biggest challenge.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Comments

Join the conversation

There is a bit of experience in using carbon fiber in race cars - IndyCar for instance. But a chassis costs hundreds of thousands of dollars and are practically custom made. Speaking of repairs, I've often wondered about how suspensions are attached to the carbon fiber frame. And how the suspension "gives away" when having an accident - allowing for new suspension parts to be re-attached. I don't think that carbon fiber can be repaired - once it is damaged - a new part is needed.

Except as it is, carbon can be toxic to cure and is not recyclable. The industry is built up around recycling old car bodies, even if composite manufacturing was suddenly cheap, the end of life issues would be challenging. However, carbon reinforced safety cages would be a tremendous thing.

I could see carbon fibre being used for things like seat and door frames. It already is for high-end Porsches and BMWs For recycling carbon fibre, there are many potential solutions; it can be ground down into pellets and mixed with tar and gravel and used in tarmac for roads.

When I saw the title, I thought Carbon Motors had given up on police cars, and was going to try selling cars to the public.