Wankel + Automatic = Ideal Truck Drivetrain?

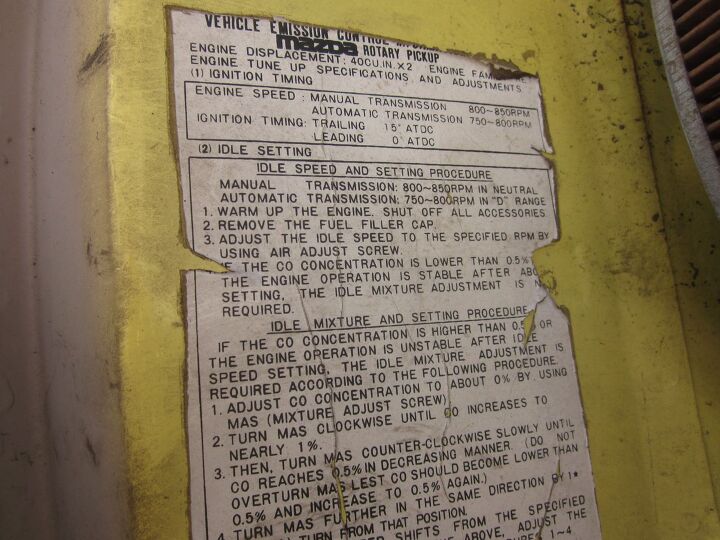

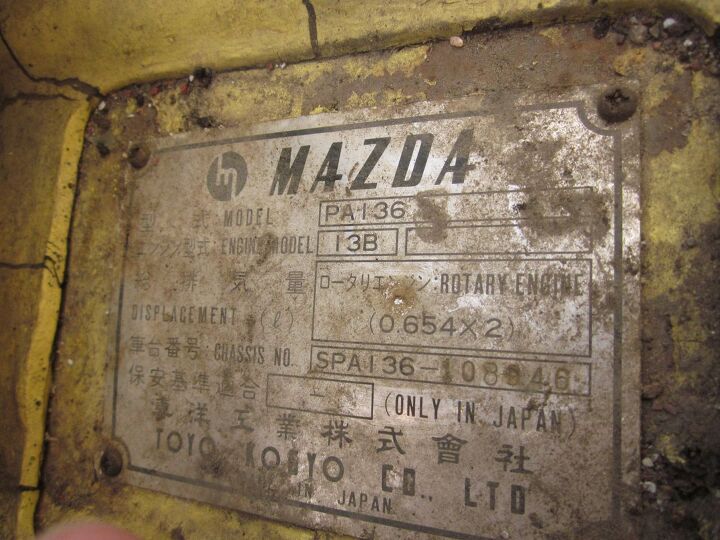

You’d think that the zilch-o-torque characteristics of a Wankel engine wouldn’t be so great for hauling heavy loads, and you’d be right! Adding an automatic transmission to the mix, as is the case with this ’75 Mazda pickup, no doubt made for some interesting driving experiences when hauling, say, a dozen sacks of concrete mix in the back.

I can’t remember the last time I saw a Mazda rotary pickup on the street, but this one— which I spotted in a Denver self-service wrecking yard a couple days ago— survived long enough to stay out of The Crusher’s way until the second decade of the 21st century.

Murilee Martin is the pen name of Phil Greden, a writer who has lived in Minnesota, California, Georgia and (now) Colorado. He has toiled at copywriting, technical writing, junkmail writing, fiction writing and now automotive writing. He has owned many terrible vehicles and some good ones. He spends a great deal of time in self-service junkyards. These days, he writes for publications including Autoweek, Autoblog, Hagerty, The Truth About Cars and Capital One.

More by Murilee Martin

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Varezhka Maybe the volume was not big enough to really matter anyways, but losing a “passenger car” for a mostly “light truck” line-up should help Subaru with their CAFE numbers too.

- Varezhka For this category my car of choice would be the CX-50. But between the two cars listed I’d select the RAV4 over CR-V. I’ve always preferred NA over small turbos and for hybrids THS’ longer history shows in its refinement.

- AZFelix I would suggest a variation on the 'fcuk, marry, kill' game using 'track, buy, lease' with three similar automotive selections.

- Formula m For the gas versions I like the Honda CRV. Haven’t driven the hybrids yet.

- SCE to AUX All that lift makes for an easy rollover of your $70k truck.

Comments

Join the conversation

I love REPU's. I would love to add one to the fleet, but this on is a bit far away I think. Very cool truck, and have a huge following amongst Rotary fans. I'm amazed this one got junked. There were two at the Deal's Gap Rotary Rally last year, and were crowd favorites. One of them was still original paint/unrestored.

I learned to drive in a '75 mazda B1600. That truck was absolutely indestructible. And, having a manual choke in hand was a great "feature". I always loved the sorta military look of the rear end.