Carbon Fiber Vs. Carbon Dioxide: German Car Maker Risks A Big Gamble

Except for a lot of green talk, my German compatriots are not known for enthusiastically embracing the EV idea. Japan, even China is way ahead of them. Despite high gasoline costs (taxes, taxes), even hybrids are everything but runaway successes in the Fatherland. If Germans want to save, they buy a Diesel, or take the train. But even the train isn’t the bargain it used to be. One car company bets big on Electric Vehicles. So big, that they built a whole new factory for them. You won’t believe who.

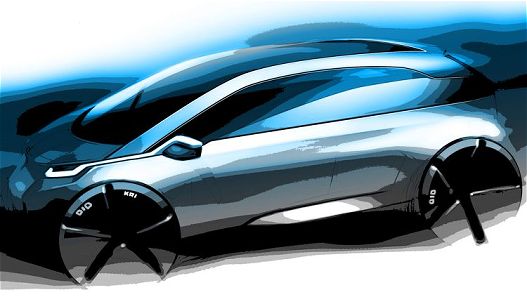

It’s BMW. With Chancellor Merkel in attendance, BMW started construction of a factory only for EVs. The plant is outside of Leipzig, and looks “like a stranded UFO,” as Die Welt reports. In 2013, the factory will churn out BMW’s EVs that currently go by the working title “Megacity Vehicle.” Instead of putting a battery and electric motors into a (more or less) existing vehicle, BMW will build a whole new vehicle around battery and electric motors. Or so they say.

Here is the big EV conundrum: The car has to lug a heavy battery around. Weight is the enemy of range. The bigger the battery, the bigger the weight. Can’t win. So BMW makes the car itself as light as possible. Instead of heavy steel, even instead of light aluminum, there will be carbon fiber. “Less weight, more range” taught CEO Reithofer the assembled press and luminaries, just in case they had slept during Newton. So get ready for a future that replaces carbon dioxide with carbon fiber.

BMW started a joint venture with SGL Carbon. They are building a factory in Washington State that will mass produce carbon fiber in an environmentally-friendly fashion. “When we make carbon fiber in our state, no harmful substances will be emitted into the air,” bragged Washington State Governor Christine Gregoire, who was also in attendance. Even the power to make the fiber is green: Hydroelectric power, there is one plus to all that rain in the Northwest.

Still, BMW has to deal with the usual problems that plague EVs. First, there is the nasty price. It won’t be cheap. But BMW customers usually don’t rely on social security. Then, there is range. Klaus Draeger, head of R& at BMW says it will go for 200km (124 miles) – no wonder it’s for megacities. Its range is barely enough for the M25, London’s ring road. In a true megacity, like Beijing, it will run out of juice before circumnavigating the 140mile long 6th Ring Road.

Then, there is a huge gamble: Currently, carbon fiber is obscenely expensive. Two to three times as dear as aluminum. Nearly 30 times as expensive than steel – if you go by weight. BMW is betting that the price of carbon fiber (and hopefully that of batteries) will come way down before they launch their Megacity Vehicle in 2013. If not, it will be a megadud.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Michael S6 Very confusing if the move is permanent or temporary.

- Jrhurren Worked in Detroit 18 years, live 20 minutes away. Ren Cen is a gem, but a very terrible design inside. I’m surprised GM stuck it out as long as they did there.

- Carson D I thought that this was going to be a comparison of BFGoodrich's different truck tires.

- Tassos Jong-iL North Korea is saving pokemon cards and amibos to buy GM in 10 years, we hope.

- Formula m Same as Ford, withholding billions in development because they want to rearrange the furniture.

Comments

Join the conversation

Battery prices aren't coming down. I don't know why no one pointed this out before, because it's so darned obvious: The lithium ion cells that are the basic building block of all EV battery packs are already a commodity item. There aren't new economies of scale or refinements of production that are going to bring cost down significantly. And these basic cells are overwhelmingly the majority of the cost of the battery pack. EV batteries are not going to get significantly less expensive. And let me make a final point: carbon fiber is similar to lithium ion. It's a mature technology. It's not going to get cheap.

The only reason cars are made of steel is because it's strong and cheap. It's heavy as hell though, but that was OK because the energy to move it around was dirt cheap. Our paradigm is based on cheap energy. Now that the power source (batteries) are expensive, it makes sense into putting the money into ways to dramatically reduce the size of that component- namely, needing less of it. It's the same as alternative energy for homes. It just isn't cost effective because our homes were designed around cheap energy, so require a lot of it. Instead of replacing that cheap energy with expensive renewables, it makes a lot more sense to limit your demand first, then go to the alternative energy. This is done by lighting that requires 1/8 the power, cooling that is 2-3x as efficient, limiting "vampire" loads, air-drying clothes, etc.