GM's Own Turbine Car Program

No, Virginia, that’s not a turbo Eldo, that’s a turbine Eldo

Paul Niedermeyer’s article and more recent book review concerning Chysler’s Turbine car show that Chrysler was savvy to use it as a halo vehicle – its appeal continues to resonate today. Though we’re learning new details all the time, most car enthusiasts know that Chrysler made a turbine powered car in the 1960s. Less well known is the fact that General Motors also had their own turbine program. While Chrysler’s Turbine Car was mostly a short lived PR effort, it happens that GM had a much longer lasting automotive turbine development program, starting in the 1950s and lasting for at least 40 years, without ever coming anywhere near to production. TTAC commenter jmo, alerted us to the existence of a powdered coal fired turbine powered Eldorado that GM developed after the oil crises of the 1970s, and we were hooked.

It shouldn’t surprise us that GM dumped a bunch of money into an idea or technology, only to abandon that investment – see also Wankel rotary, Fiat, Hughes, et al. Still, not many people, besides jmo that is, know that GM also had a running prototype of a turbine powered car, and it ran on coal to boot. Turbines have been one of the more popular automotive pipe dreams (though there have been successful applications of turbines in large trucks and most famously the M1A1 Abrams tank). Apparently starting in the late 1950s with a Boeing aircraft turbine shoehorned into a two-seat T’bird, Ford had its own gas-turbine program under manager Connie Bouchard. Bouchard said that the non-regenerative turbine in the prototype put out so much exhaust heat that roadside grass and weeds would catch fire. Ford Motor Company now says that it was a regenerative low pressure turbine installed in a 1954 model, which couldn’t have been a Thunderbird. The Big Three Detroit automakers were all attracted to turbines’ long life, lower maintenance costs, low weight and smooth vibration-free running. It was hoped that development would get over the barriers of high cost and relatively high fuel consumption.

Some of GM’s most dramatic show cars, the Firebirds of the 1950s Autoramas, actually had turbine engines and apparently were not just static show cars (though the Firebird I so easily broke the rear tires free that race car driver Maury Rose ended up doing some of the testing at Indy). While the Firebirds actually could drive, in a manner of speaking, some of their show car features were pure science fiction at the time.

GM had started research on turbines in the 1930s and their Allison division was building aircraft jet engines by the 1950s.

GM put Emmett Conklin in charge of the project to build the powerplants for three of Harley Earl’s most famous (and outrageous) show cars.

The Firebird I was a single seater, weighing only 2,500 lbs and had a 370 hp turbine driving the rear wheels. GM dubbed their in-house turbine the “Whirllfire Turbo Power” engine. It had a two-speed transmission (probably an early Powerglide), and it’s exhaust was hot enough to melt plastic and blister paint if you happened to be sitting behind it in traffic, 1,250 °F. In addition to air cooled brake drums, the Firebird I used air flaps to slow the car at speed.

For the 1956 Autorama, a slightly more practical Firebird II was introduced. It was a family vehicle with four seats, and per au courant jet design themes, a canopy top, and two huge circular air intakes that make me think of 1950s science fiction robots. Again, keeping with the jet theme, Earl had one of the two Firebird II bodies fabricated out of unpainted titanium. In 1956 that must have been outrageously expensive. Engine output was down to 200 HP but engine heat was less of a problem as a regenerative system allowed the motor to run about a thousand degrees F cooler as well as power the accessories.

1959’s Firebird III, the only one of the 3 that comes close to looking like a car, was a two-seater with two canopy bubbles. By then the engine’s name was changed to the “Whirlfire GT-305, with 225 hp (168 kW) to the wheels and a small 10 hp gasoline engine to run all the accessories.

According to a forum on GM Inside News, William Turunen headed GM’s automotive turbine program for most of its life. Albert Bell III’s name also frequently pops up in accounts of GM turbine cars. Bell went to his grave believing that the turbine could still be a practical car motor.

Bell was involved when GM recycled the turbine as a response to the oil shortages of the 1970s. Though turbines aren’t particularly gas misers, they can run on a variety of flammables, including perfume, and in this case coal dust. Don’t laugh, Rudolph Diesel’s earliest experiments with compression ignition engines used coal dust as a fuel. To be clear, those experiments failed, forcing Diesel to switch to fuel oil, but coal dust has a lot of BTUs. America also has a lot of coal, 500 billion tons of it, at least half easily recoverable. It’s also cheaper per btu than just about any other fuel, hence GM’s interest in a coal burning engine in the late 1970s.

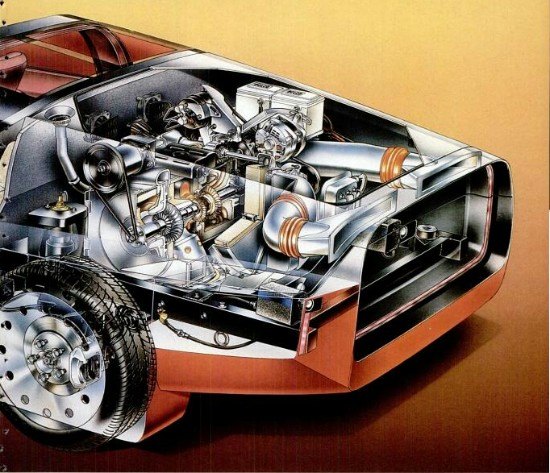

GM Photo from Automobile Magazine

As a test mule, GM used the last full sized Eldorado, the 1978 model. The 1979s were already in production but they were downsized. The big Eldo’s cavernous engine compartment, designed to take a 500 CI big block with ease, and its gigantic trunk, capable of carrying a foursome’s clubs and luggage for a long golfing trip (or, if you prefer a different metric, as many hookers, dead or alive, as your little heart desires), had more than enough room for whatever machinery the prototype needed.

And the prototype indeed needed special machinery, … of the Rube Goldberg variety according to retired GM engineer John Schult, who described the system to the NY Times in 2009:

“To keep the coal dust ready for delivery to the engine, it had to be continuously agitated. Then a small conveyor belt delivered the coal to the gasifier, the first section of G.M.’s automotive turbine engine. When you stepped on the gas pedal, it actually moved a potentiometer that varied the speed of the coal conveyor belt. More fuel resulted in more power.”

Schult said that the fuel delivery system added additional delay to the lag that automotive turbines experienced. Schult did point out that the car did launch fairly well due to turbine’s high torque at low engine speeds. Shult didn’t mention if GM ever learned that if you brake-torque a turbine car and let the motor spool up to full speed, it develops, like electric motors, maximum torque at stall, and makes an excellent drag strip car, turbine lag or not. The experimental Eldorado’s turbine, which idled at a non-automotive 35,000 RPM, was geared down and that power was fed to a standard 3 speed THM transmission.

The car had a small tank of diesel/kerosene for starting the turbine. Once fired, it automatically changed over to the coal dust. Schult said that with the turbine whine and buzz of the coal dust agitator, plus compressed air blowing the dust into the gasifier, it didn’t sound much like a conventional Detroit V8 engine.

Only a single prototype was made. Apparently refueling was about as messy as changing toner powder on a copier machine, getting greasy coal dust everywhere.

Nobody knows what happened to the one coal powered Eldorado. Schult and fellow GM retiree Paul Ulrich say that the car was shipped to Allison when the project was moved there. That’s where the trail ends.

That was not the end of the dream of turbine power for cars at General Motors. In the April 1987 issue of Popular Science, right after an ad for the “first ever Star Trek collector plate” (of Mr. Spock) is an article by Dan McCosh about the Chevy Express, a 150 mph turbine powered concept that from its styling appears to have been part of GM’s EV1 program.

The Express concept, which appeared in one of the Back To The Future movies, was powered by an ACT-5 turbine with a regenerator, developed by a team headed by Albert Bell.

GM continued to work into the 1990s on automotive turbines, when the program was moved to GM’s Allison division, which had done the actual work on the prototype coal turbine. GM’s automotive engineers shifted emphasis to fuel cells and other projects, since the high exhaust temperatures and oxides of nitrogen that turbines produce create issues with emissions regulations.

That wasn’t the end of turbine cars at GM. Also as part of the EV1 program, at the 1998 North American International Auto Show in Detroit GM revealed a number of alternative EV1 drivetrain concepts, including the EV1 Series Hybrid Concept. In range extended mode, the EV1 Series Hybrid used an auxilary power unit powered by a small turbine developed with Williams International. In one of those Detroit ironies, Williams International was founded by Sam B. Williams, who as a young engineer worked at Chrysler on their turbine project.

According to AutoWorld, the EV1 Series Hybrid concept’s APU was, at the time, the smallest, lightest and most efficient APU made. The single-stage, single-shaft recuperated gas turbine was integrated into a single compact cylindrical unit with a 40 kW AC generator.

As the Chevy Volt is just now coming to market, it’s interesting to note the performance specs for the EV1 Series Hybrid concept of 1998:

Still, hope springs eternal. Earlier this month Jaguar introduced the C-X75 serial hybrid concept, with a serial-hybrid genset driven by a pair of… micro turbines.

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- 1995 SC I wish them the best. Based on the cluster that is Ford Motor Company at the moment and past efforts by others at this I am not optimistic. I wish they would focus on straigtening out the Myriad of issues with their core products first.

- El Kevarino There are already cheap EV's available. They're called "used cars". You can get a lightly used Kia Niro EV, which is a perfectly functional hatchback with lots of features, 230mi of range, and real buttons for around $20k. It won't solve the charging infrastructure problem, but if you can charge at home or work it can get you from A to B with a very low cost per mile.

- Kjhkjlhkjhkljh kljhjkhjklhkjh haaaaaaaaaaahahahahahahahaha

- Kjhkjlhkjhkljh kljhjkhjklhkjh *Why would anyone buy this* when the 2025 RamCharger is right around the corner, *faster* with vastly *better mpg* and stupid amounts of torque using a proven engine layout and motivation drive in use since 1920.

- Kjhkjlhkjhkljh kljhjkhjklhkjh I hate this soooooooo much. but the 2025 RAMCHARGER is the CORRECT bridge for people to go electric. I hate dodge (thanks for making me buy 2 replacement 46RH's) .. but the ramcharger's electric drive layout is *vastly* superior to a full electric car in dense populous areas where charging is difficult and where moron luddite science hating trumpers sabotage charges or block them.If Toyota had a tundra in the same config i'd plop 75k cash down today and burn my pos chevy in the dealer parking lot

Comments

Join the conversation

Anyone. Please show one, just one, example of a turbine-powered vehicle that achieved anywhere near the fuel economy (let alone drivability) of an equal HP/TQ ICE. Just one. Can't? Shocking. Turbines are neat for a few applications. Automotive ain't one of them.

Ronnie, I can tell you what happened to the 1978 Blue and Silver Coal powered Eldorado, it was trash compacted. My father Richard Stettler and his friend and co-work Everett Showes, worked under Al Bell, designed and held the original patent to that engine, I was the girl in the picture next to it as it sat in our driveway in Birmingham, MI. My father and Mr. Showes retired from General Motors Corporation and left the Tech Center in 1986, the patent was sold to Detroit Diesel Allison, both of them spent the next two years in Indianapolis working on that engine in conjunction with DDA. That car was also displayed for a brief time in Epcot center in Florida. Lisa Stettler-Christin