Lotus Adds Lightness… To The Toyota Venza?

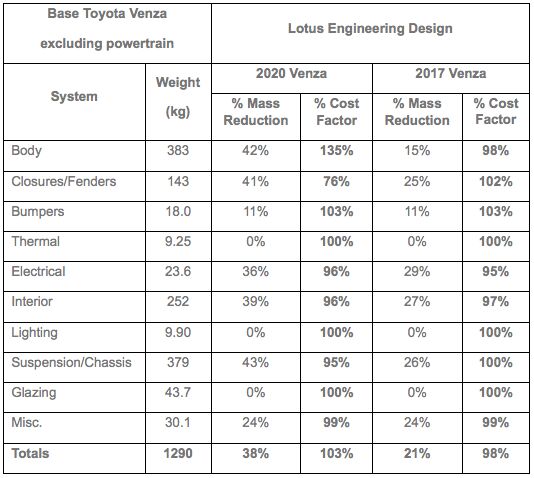

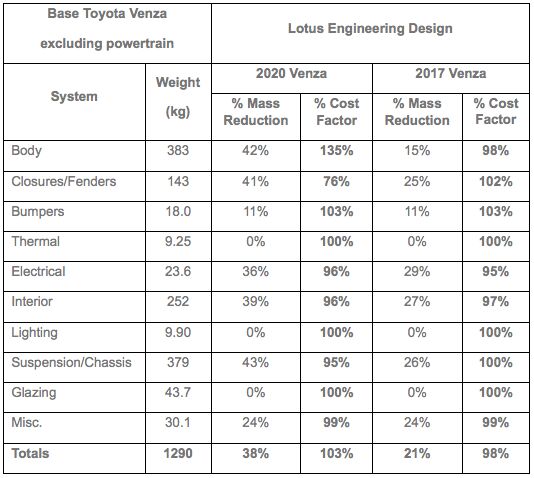

In a study for the International Council on Clean Transportation [ full study in PDF format here], Lotus Engineering sought to prove that major reductions in the mass and fuel consumption of mass-market vehicles would be possible by 2020 through the use of new materials and architectures. Starting with a Toyota Venza crossover, Lotus was able to show that a 38 percent reduction in vehicle mass (not counting the powertrain, 33 percent reduction including powertrain) will be possible with a mere three percent increase in component costs. Based on DOE estimates, that means the Venza’s efficiency could be improved by 23 percent solely through changes in materials and design, with future powertrain efficiency gains adding cumulative benefits.

The study also considered a 2017 model-year concept, and found that a similar program of weight-saving could reduce vehicle mass by 21 percent (excluding powertrain) and actually reduce costs by two percent. Weight and cost reductions are summarized below.

The moral of the story? Reducing the weight of new vehicles remains an effective option for improving efficiency without huge cost increases. Lotus may have picked an easy target for weight reduction in the 5,000+ pound, five-passenger Venza, but it’s still an effective demonstration of Colin Chapman’s principles.

More by Edward Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Lorenzo The Longshoreman/philosopher Eri Hoffer postulated "Every great cause begins as a movement, becomes a business, and ends up as a racket." That pretty much describes the progression of the United Auto Workers since World War II, so if THEY are the union, the answer is 'no'.

- Redapple2 I think I ve been in 100 plants. ~ 20 in Mexico. ~10 Europe. Balance usa. About 1/2 nonunion. I supervised UAW skilled trades guys at GM Powertrain for 6 years. I know the answer.PS- you do know GM products - sales weighted - average about 40% USA-Canada Content.

- Jrhurren Unions and ownership need to work towards the common good together. Shawn Fain is a clown who would love to drive the companies out of business (or offshored) just to claim victory.

- Redapple2 Tadge will be replaced with a girl. Even thought -today- only 13% of engineer -newly granted BS are female. So, a Tadge level job takes ~~ 25 yrs of experience, I d look at % in 2000. I d bet it was lower. Not higher. 10%. (You cannot believe what % of top jobs at gm are women. @ 10%. Jeez.)

- Redapple2 .....styling has moved into [s]exotic car territory[/s] tortured over done origami land. There; I fixed it. C 7 is best looking.

Comments

Join the conversation

Subaru beat everyone else to the punch with this, using smart manufacturing and new technologies to make the 05-09 Legacy a remarkably lightweight car (3200 with AWD, which is only a few hundred above the original Impreza) while still being the most refined, safest and best built car they've ever made. Then, in typical Subaru fashion, they totally undid it for the 2010 model and made it another bloated family sedan in a fatsuit. Bizarre engineering decisions. It's what makes a Subaru, a Subaru.

Just a point to clear up an error in the article. The Venza’s weight starts at 3760 lbs. Even with the V6 AWD, it’s just a tad over 4000 lbs. Heavy, yes, but not “5,000 +” lbs.