"Tin Whiskers" Implicated In Unintended Acceleration Problems

A number of articles have appeared implicating tin whiskers as a potential source or complicating factor in Toyota’s (and other manufacturers’) unintended acceleration issues. The phenomenon of tin whiskers, a crystalline metallurgical phenomenon involving the spontaneous growth of tiny, filiform hairs from a metallic surface, can cause short circuits and arcing in electric equipment. First discovered in phone switching equipment in the 1940’s, the addition of lead to tin solder largely eliminated the problem. But the push to eliminate lead from electronic assemblies has led to a nasty re-growth of the pesky whiskers. And some are pointing fingers.

Satellites, including the failure of Galaxy IV, nuclear power facilities,pacemakers, and numerous other electronic assemblies have suffered from the effects of tin whiskering ( here’s an explanation). In an article at TechEYE.net, a document that details the issues with lead-free soldering is referred to. Another expert in the field Henning Leidecker, chief engineer of the electronic parts office of NASA’s Goddard Space Flight Center in Greenbelt, Md., and an expert on tin whiskers, said in the last four years his office has been contacted by seven major suppliers of automotive electronics inquiring about failures in their products caused by tin whiskers.

More by Paul Niedermeyer

Comments

Join the conversation

There is a quick fix for the tin whisker problem: http://www.youtube.com/watch?v=5ziP3FBbR2I http://www.hybridplastics.com/docs/tds/ShortStop.pdf

Funny, when I posted this news blog about tin whiskers a couple years ago, most commentators didn't think it would be a problem. http://www.thetruthaboutcars.com/auto-electronics-could-get-buggier-still/

Having recently purchased a 2010 Flex, I experienced a brief unintended acceleration incident. Actually it was the second occurrence within a week, the first occurring during a test drive of the same model vehicle from a different Ford store. That said, I was engaged as a Materials Scientist by a very large computer firm back in the 1970s. Metal migration (whiskers / fibers) was a great cause for concern. It was a well known failure mechanism within semiconductors and their packages. This was particularly troublesome in industrial or environmentally hostile operation environments (like under the hood of a car.) The rapid advances in manufacturing technology allowed increasing device densities but also increased the propensity for this failure mode at the device level. Many proprietary changes in metallurgy and fabrication methods were tried before satisfactory solutions were implemented. Now nearly 50 years later, reading of this phenomena, is mind boggling. We do seem to be constantly having to reinvent things because we fail to be willing to borrow from history lessons.

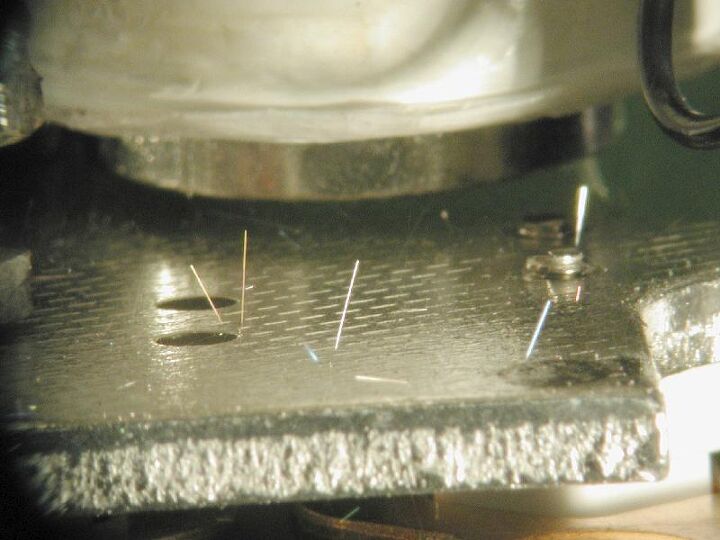

Has anyone here seen a tin whisker? I have (I have some samples from NASA). Until I saw them, I had no idea what I was looking for. Thanks to an invitation from a scientist at NIST, I have been participating in an aerospace industry weekly teleconference on tin whiskers for the past two years. Participants, including myself have consider it possible that tin whiskers could be responsible for sudden acceleration and other odd behavior in automobiles manufactured after 2002-2003. Dr. Gilbert of Southern Indiana University has participated in the teleconference and shared with us what he had learned (I was the one who invited him to attend). Dr. David Gilbert has demonstrated that a low resistance or shorted input between the wires from the pedal electronics to the electronics control module will cause Toyotas to open their throttles full. A tin whisker could induce such a short and as Dr. Gilbert proved, pushing as hard as you can on the brake pedal will not overcome the throttle being held full open. Perhaps the problem is due to leadfree manufacturing (which Toyota states on its website it began in 2002-3)? Perhaps it is software? We don't yet know but we can be reasonably certain that not all the accidents are caused by the owners of the vehicles. You can see pictures of the Toyota parts at my website [www.hlinstruments.com//RoHS_articles/Toyota/] The pedal assembly has a printed circuit board layout that is not as well designed as it could be. In particular, the tiny integrated circuit that converts the signals from the Hall effect sensors (that senses pedal position via a magnet attached to the pedal arm) into 1-5Vdc signals sent to the electronic control module is very close to the edge of the board. The board has serrated edges which indicates it was snapped out of a large panel of these boards after the parts were soldered to it. It's possible a trace or lead has fractured or one of the capacitors or resistors. We know that leadfree solder is more brittle than tin-lead. Perhaps a few boards are marginal and over time a lead opens or becomes intermittent? Whiskers are very hard to find. Only about 20% of them are visible to the naked eye and only in light reflecting off them at a certain angle. The remainder require a microscope and to see them in great detail you need a scanning electron microscope with an X-ray fluorescence detector. Not something you average auto repair shop has. Even if tni-lead solder is still being used, the components themselves, thanks to RoHS, are now mostly pure tin plated. Some companies have the gall to advertise their tin platings won't grow whiskers. Only time will tell if that's true. The standard (industry approved test) for whisker proof tin finish (JESD-201) is 4000 hours and the resulting whiskers can be no longer than 50 microns (0.002"). 4000 hours is less than a year. What happens after 4000 hours? Your guess is as good as mine. To quote a NASA researcher friend (Lyudmyla Panashchenko), "sometimes tin whiskers". Auto dealers call another friend of mine (Dr Henning Leidecker) at NASA Goddard Space Flight Center, who is one of the world's experts on the subject of tin whiskers. This is why the US DOT contacted NASA to investigate Toyota's problems. And, by the way, DOT may have said they found no problems, but NASA isn't finished with it's investigation nor is the National Academy of Sciences. Dr. Leidecker said that in the last four years his office has been contacted by seven major suppliers of automotive electronics inquiring about failures in their products caused by tin whiskers. He said his office has contacted Toyota offering to help analyze its acceleration problem, but hasn't heard back. For full context, read the rest of the article [http://wtop.com/?nid=108&sid=1898265]. It's not just the removal of lead from tin-lead solder that is a potential whisker problem, its' that parts are now being plated in pure tin and they can grow tin whiskers "with a certain amount of aging". According to NASA, whiskers can grow in hours, days, weeks, months or years. It depends on at least six factors; the quality of the tin plating, the residual stress in the coating, was the coating annealed or not, grain uniformity, temperature, humidity, and unknown other factors we don’t yet understand which is what makes it so difficult to stop whiskers from growing and is why there are so many papers published on the subject yet we still do not understand why or how they grow. So yes, is entirely within the realm of possibility that "new" products have failed due to tin whiskers or perhaps dendritic growth. NASA cannot tell us who the manufacturers are who reported these events due to confidentiality agreements. Dr. Leidecker says they get these calls from other industries as well and most request a non-disclosure agreement. NASA feels it’s better to get some information rather than none, don't you agree? A few months ago I was at the 4th International Conference on Tin Whiskers at CALCE at the University of Maryland where it was reported that 31% of all laptops fail within 3 years. This is the link to the report http://www.squaretrade.com/pages/laptop-reliability-1109/ No information is given as to what has failed. Is it due to whiskers? We do not know. What we do know is that the laws of physics have not been repealed. Tin will most certainly grow whiskers so using leadfree solder and tin plated components has to result in tin whiskers growing. NASA continues to log failures. NASA Goddard has signed a non-disclosure statement so they cannot comment on the study at this time. The EU was warned that tin whiskers and brittle joints would result if lead was banned from electronic assemblies but went ahead and banned lead from tin-lead solder and platings on parts. They acknowledged the possibility of reduced reliability under intense pressure from hi reliability industries and did exempt some products (military, aerospace, etc...). What difference did it make since the majority of component manufacturers refused to continue to offer tin-lead plated leads? That is why NASA replates it's components with tin-lead at Corfin Industries and uses only tin-lead solder.