A Renaissance For The Automotive Steam Engine?

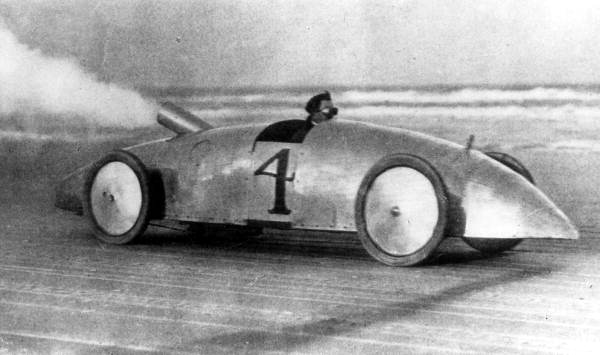

The steamer is the granddaddy of all engines, dating back some 2,000 years. All of the earliest “cars” were steamers, and the golden age of steam cars in the teens and twenties resulted in some fabulously refined vehicles. The Stanley was very successful and set the world speed record in 1906 that was only broken recently; and the ultimate development, the highly refined Doble, created a legend. The advantages of the steam engine are the ability to burn almost any kind of fuel, generate maximum torque at starting rpm, no need for a transmission, and the ability to power the loudest of horns. There have been numerous attempts at automotive steam engine revivals; but their many downsides have relegated them to the obscure pages of wikipedia: delay in getting up a head of steam, bulky condensers, oil contamination of the steam, inefficiencies, etc.. But Cyclone Power Technologies has been developing a radical update on a compact, efficient, eco-friendly steam engine. Before we dismiss it as more hot vapor in our usual dismissive TTAC manner, let’s take a closer look first:

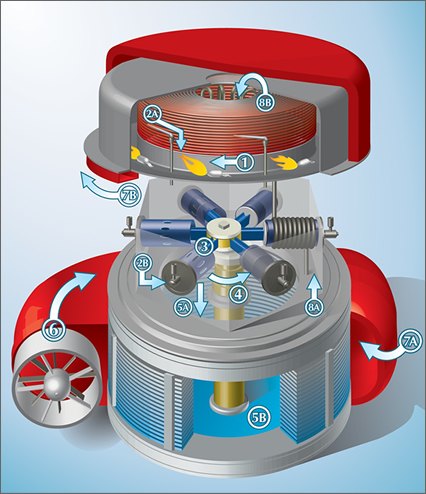

Under development for quite some time, Cyclone claims to have addressed all the shortcomings of steamers in one compact package. For a detailed explanation, go here, or here’s my Cliff Notes version: almost any fuel can be burned in the flash boiler (1), which super heats water to 1200 degrees F in as little as five seconds. Steam powers the pistons in the radial engine (4), which spins on hi-tech ceramic bearings that are lubricated only by water. There is no need for any type of oil for lubrication, eliminating contamination and the need for oil changes, etc. Spent steam enters the condensing unit (5B), where a fan powered heat exchanger preheats the intake air for more efficient combustion. Cyclone promises efficiencies comparable to gas and diesel engines, potentially even higher, depending on the fuel and its source (orange peel oil, for instance). Emissions for external combustion engines are intrinsically low. Sound perfect? Well, there are a few issues to sort out. But it should smell good burning that orange peel oil.

First, Cyclone has yet to complete development of the whole integrated package. They’ve operated the engine and various components separately, but not as contemplated here. The engine is going to be used for US Land Steam Record Team in their attempt to break the world land speed record for steam vehicles in Bonneville, UT, as early as next August (see separate post).

The warm up time is still an issue. Cyclone says ten to fifteen seconds to generate steam, but that’s not a full head. That will take about a minute or more. And that’s all dependent on how cold it is outside. No quick morning get-aways. Well, remote starters would deal with that. Questions as to mass-production build costs are unknown, as well as the reliability of the water-lubricated engine.

There are two main attractive features that will likely keep Cyclone in development money for at least a while longer. Number one is the ability to burn almost any type of fuel from orange peels, palm oil, cottonseed oil, algae, used motor oil and fryer grease, as well as traditional fossil fuels, propane, butane, natural gas and even powdered coal. In a post-oil world, that might come in handy. By then, they should have it fleshed out.

The other intriguing possibility is in using waste heat to generate the steam. Theoretically, a diesel truck engine could be combined with a Cyclone, running mainly off the diesel’s exhaust, and burning additional diesel if needed to provide a quick burst of extra power. It lends a whole new meaning to the word hybrid . In a scenario like this, efficiencies of up to 55% or greater could be contemplated. That compares to about 30 to 35% for the diesel alone. For a more extensive discussion on this and other possibilities, head over to GreenCarCongress’ article on the Cyclone.

The verdict? It sounds more promising than the steam-injected Bobcat by the length of a Bonneville record run. But then I’m old enough to remember reading several articles titled “A Renaissance For The Automotive Steam Engine?” or something along those lines in Popular Science over the decades. So here’s my addition to the genre. I somehow suspect it won’t be the last either.

More by Paul Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Master Baiter There are plenty of affordable EVs--in China where they make all the batteries. Tesla is the only auto maker with a reasonably coherent strategy involving manufacturing their own cells in the United States. Tesla's problem now is I think they've run out of customers willing to put up with their goofy ergonomics to have a nice drive train.

- Cprescott Doesn't any better in red than it did in white. Looks like an even uglier Honduh Civic 2 door with a hideous front end (and that is saying something about a Honduh).

- Kwik_Shift_Pro4X Nice look, but too short.

- EBFlex Considering Ford assured us the fake lightning was profitable at under $40k, I’d imagine these new EVs will start at $20k.

- Fahrvergnugen cannot remember the last time i cared about a new bmw.

Comments

Join the conversation

Water-lubricated ceramic bearings to eliminate oil-changes? The lubrication of bearings was never a problem with steam engines. It is the lubrication of cylinders, especially when using superheated steam at very high pressures that caused problems, or rather separating the oil from the exhaust steam before condensing.

A true hybrid indeed. I have always thought that a simple car which runs on banana peels - even badly - would be infinitely more progressive than a complex car which merely extracts a few more BTUs from the last few barrels of oil. It's more Harrowsmith than Ward's, but innovation often does come from the last place you'd look. The only question is what to do about Al Gore. One can only imagine the pressure to send billions of dollars to developing nations struggling under the devastating effects of Global Peeling.