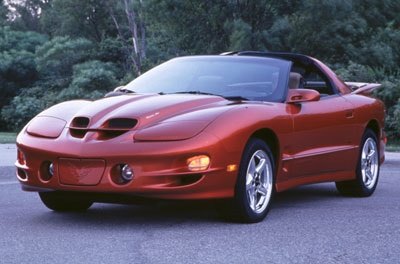

Piston Slap – Poncho Muscle Flex and Panic at the Opera (light)

Mikey, TTAC’s personal window into the CAW, writes:

My 2001 Firebird 3800 V6 convertible will shear left hand motor mount bolts and break them off in the block. The first time it happened my mechanic replaced the original bolts with 8.8 hardness. It took 2 years and 15000 kms for them to shear again. This time he went to aircraft quality bolts: so far so good, but the car hasn’t moved 2000 kms since.

The car was 5yrs old when I bought it. I don’t THINK it’s been hit. I can’t see obvious evidence nor can my mechanic. The trans support/mount looks ok, it tracks fine and tire wear isn’t an issue. One would think a bent K-member might be the culprit? But then you would have alignment problems would you not?

My mechanic looked at the engineering of the mounts.The engine is suspended as opposed to being in cradle. He figures that [be]cause GM was in such a hurry to put the 3800 in production that they just reworked the (60-degree V6) 3.1 engine mounts. The extra torque and weight of the 90 degree 3.8 v6 was too much strain? I don’t drive hard or fast, but our roads suck. I’ve owned lots of convertibles and they do twist and turn and rattle. Could these factors cause my problem?

Sajeev responds:

Mikey, you mentioned replacing the bolt, but have you changed the rubber part of the engine mount? And is the LS1/LT1 mount beefier and compatible? I say this because the diff-to-frame mount on my car had a slightly compressed bushing, a fraction of a millimeter was squished down. No big deal, I thought: but it was the source of a vibration above 65mph. And vibrations can lead to broken bolts.

After that, rule out the K-member by having a body shop (with a laser-guided chassis rack) check the frame: it’s possible that it’s bent enough to mess with the mounts but not go beyond the parameters of a front-end alignment. Not likely, but it’s good to know for sure.

Hopefully one of these two will address the problem. If not, screw it and do an LS-1 swap.

SexCpotatoes writes:

I was hoping to pick your brain in coming up with a workable, totally brilliant modification to one of my cars. I want to replace the opera lights on my ’91 Grand Marquis with strips of LEDs. I want them to light up, in sequence bottom to top, based on how much throttle is applied. I’ve thought of two different ways to do this:

1. Tap into the Throttle Position Sensor wiring and use some sort of cheap, dumb circuit board to vary the lights on the pillars.

2. Install a digital Tachometer, and link said imaginary circuit board to it, so that lights increase with engine RPMs.

I don’t have the electronics knowledge to know what type of circuits I need to buy, etc. I could really use some help in pointing me in the right direction, as I think I’m the first person to ever come up with this idea, and would love to implement it.

Sajeev responds:

I can’t help with the circuit board conversion of the Ford signal to your LED lights, but I would not tap the TPS sensor because it’s an input for the engine computer.

The tachometer is a logical choice, but I have a better idea: tap into pin #34 of the EEC-IV computer so the lights run off fuel flow calculations. That’s a calculated output from the computer, not an input used for engine control. If you’ve upgraded to mass-air Mustang stuff, that PIN exists, even if the wiring diagrams say otherwise.

Pin #34 will give you the signal you need. Don’t ask me how I know.

[Contact Piston Slap with your technical queries @ sajeev.mehta@thetruthaboutcars.com]

More by Sajeev Mehta

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy I am slashing my food budget by 1%.

- ToolGuy TG grows skeptical about his government protecting him from bad decisions.

- Calrson Fan Jeff - Agree with what you said. I think currently an EV pick-up could work in a commercial/fleet application. As someone on this site stated, w/current tech. battery vehicles just do not scale well. EBFlex - No one wanted to hate the Cyber Truck more than me but I can't ignore all the new technology and innovative thinking that went into it. There is a lot I like about it. GM, Ford & Ram should incorporate some it's design cues into their ICE trucks.

- Michael S6 Very confusing if the move is permanent or temporary.

- Jrhurren Worked in Detroit 18 years, live 20 minutes away. Ren Cen is a gem, but a very terrible design inside. I’m surprised GM stuck it out as long as they did there.

Comments

Join the conversation

Good luck, Mikey. :) SexCPotatoes: I’ve got the instructions for conversion to four always on high/low beams bookmarked on Grandmarq.net, and I also want to convert the “brights” switch to a kick-on brights switch on the floor (like is in my brother’s ‘79 F-250), but those changes should be relatively simple compared to figuring out how to make a (relatively) affordable dual-sequence LED fuel flow display mod. I’m definitely converting it to the 3-G alternator setup before messing with any wiring though. 3G alternator is excellent, don't forget the big gauge power wire too. But that probably won't affect the four headlight conversion...my quad headlight Continental has a puny alternator and runs all four from the factory. (And it's never caught on fire!)

Replacing the opera lights with a strip of LEDs whose illumination is based on throttle position sounds cooler than what the reality likely will be. If you are like most people, most of your driving is at a very low throttle position, and rarely touch WOT. Unless you drive like a idiot, or idle at traffic lights with the throttle wide open, most of the time, your LEDs will be mostly dark.